At its core, PTFE vials are considered environmentally friendly primarily because of their exceptional durability and chemical inertness. This allows them to be reused extensively in demanding laboratory settings, drastically reducing the consumption and disposal of single-use alternatives over time.

The environmental benefit of PTFE is not rooted in its production, which has notable concerns, but in its performance. Its long service life and reusability can lead to a significant net reduction in laboratory waste when managed correctly.

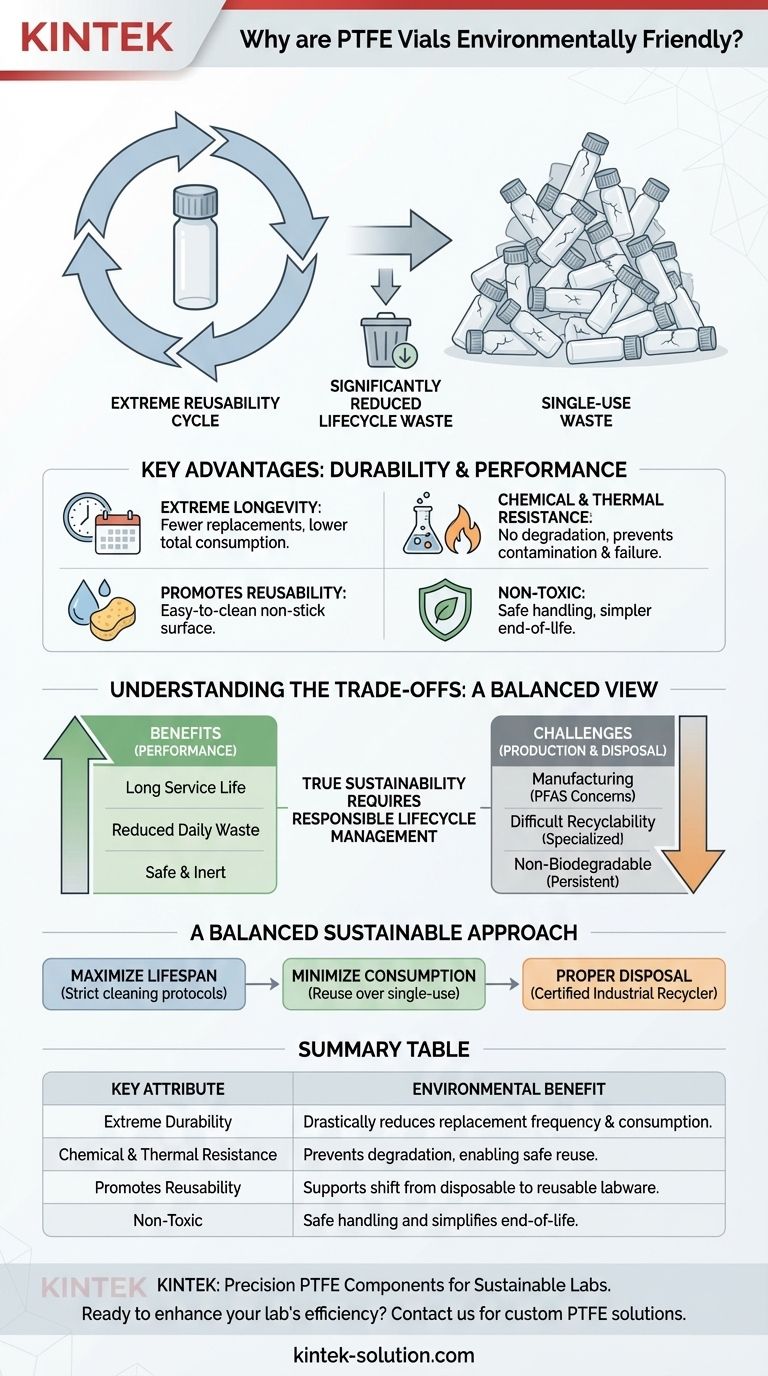

The Foundation of PTFE's "Green" Claim: Unmatched Durability

The primary argument for PTFE's environmental friendliness is its lifecycle. By lasting significantly longer than other materials, it reduces the overall need for manufacturing, shipping, and disposal.

Extreme Longevity Reduces Replacement Cycles

PTFE is an incredibly durable material. Vials made from it withstand physical stress far better than many common plastics or even glass in some applications.

This resilience means they are replaced far less frequently, leading to a substantial reduction in the total number of vials consumed over years of lab work.

High Chemical and Thermal Resistance

PTFE is famous for being chemically inert and resistant to high temperatures (up to 260°C or 500°F).

This means it won't degrade, leach, or react when exposed to harsh solvents or extreme heat. Vials maintain their integrity, preventing sample contamination and eliminating the need to discard them due to material failure.

A Lifecycle Approach to Waste Reduction

When you consider the entire lifecycle, the impact of manufacturing one PTFE vial that can be used hundreds of times is often far lower than manufacturing hundreds of single-use plastic vials that are discarded after one use.

Beyond Durability: Secondary Environmental Benefits

While durability is the main factor, other properties contribute to PTFE's sustainable profile in a lab environment.

Promoting Reusability in the Lab

Unlike many disposable plastics, PTFE's non-stick, inert surface makes it easy to clean thoroughly for reuse.

This directly supports a core tenet of laboratory sustainability: transitioning from a disposable-first to a reusable-first mindset, which immediately cuts down on daily waste generation.

Non-Toxicity for Safer Handling

PTFE is non-toxic and has been approved by the FDA for food-contact applications.

This quality ensures it doesn't pose a health risk during handling and simplifies its end-of-life management, as it is not considered hazardous waste.

Understanding the Trade-offs: The Full Environmental Picture

To make an informed decision, you must weigh PTFE's benefits against its known environmental drawbacks. The "environmentally friendly" label is highly dependent on context.

The Challenge of Recyclability

While some sources claim PTFE is recyclable, this is not straightforward. It cannot be melted and reformed like common plastics.

Recycling PTFE is a specialized, industrial process that grinds it down for use as a filler or additive. This process is not widely accessible, meaning many PTFE products are ultimately sent to a landfill.

The Manufacturing Concern: PFAS Chemicals

This is the most significant counter-argument. The production of PTFE is historically linked to the use of per- and polyfluoroalkyl substances (PFAS), often called "forever chemicals."

These substances are persistent in the environment and have been associated with harmful environmental and health effects. Choosing PTFE means accepting the environmental burden of its manufacturing process.

Durability vs. Biodegradability

The same chemical stability that makes PTFE durable also means it will not biodegrade. If a PTFE vial ends up in a landfill or the natural environment, it will persist for centuries.

Proper disposal through designated industrial waste streams is therefore critical to preventing long-term pollution.

Making the Right Choice for Your Lab

Your decision should be based on a clear understanding of your laboratory's specific sustainability priorities and operational realities.

- If your primary focus is minimizing daily waste and long-term costs: PTFE is an excellent choice due to its extreme reusability and durability, which drastically cuts down on the consumption of single-use plastics.

- If your primary focus is avoiding materials linked to "forever chemicals": You should investigate and validate PTFE-free alternatives, as the production of PTFE has a significant and well-documented environmental impact.

- If your primary focus is a balanced, sustainable approach: Maximize PTFE's lifespan with a strict cleaning and reuse protocol to offset its production impact, and partner with a certified industrial recycler for end-of-life disposal.

Ultimately, true sustainability requires evaluating a material's entire lifecycle, from creation to disposal, not just a single attribute.

Summary Table:

| Key Attribute | Environmental Benefit |

|---|---|

| Extreme Durability | Drastically reduces replacement frequency and overall consumption. |

| Chemical & Thermal Resistance | Prevents degradation, enabling safe reuse and eliminating disposal due to failure. |

| Promotes Reusability | Supports a shift from disposable to reusable labware, cutting daily waste. |

| Non-Toxic | Safe handling and simplifies end-of-life management. |

Ready to enhance your lab's sustainability and efficiency with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our commitment to quality ensures your PTFE vials and other products offer the unmatched durability and chemical resistance needed to maximize reuse, reduce waste, and lower long-term costs.

We provide custom fabrication from prototypes to high-volume orders, tailored to your specific requirements. Let us help you make a smarter, more sustainable choice for your laboratory.

Contact us today to discuss your PTFE needs and request a quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are PTFE stirring shafts and what styles are available? Select the Right Impeller for Your Lab

- What are the temperature limits for the PTFE bottle? Ensure Safety from -200°C to 260°C

- Why are needle penetration and self-sealing properties important in PTFE-coated septums? Ensure Sample Integrity in Your Lab

- What types of PTFE-lined bottle caps are available? Find the Perfect Seal for Your Application

- What customization options are available for PTFE-lined bottle caps? Tailor Caps for Chemical & Temperature Resistance

- Why are PTFE filters advantageous for gravimetric analysis? Achieve Unmatched Accuracy and Precision

- Why are PTFE syringe filters indispensable? For Superior Chemical Resistance and Sample Integrity

- How does the transparency feature of PTFE vials aid in laboratory work? Enhance Visibility and Efficiency