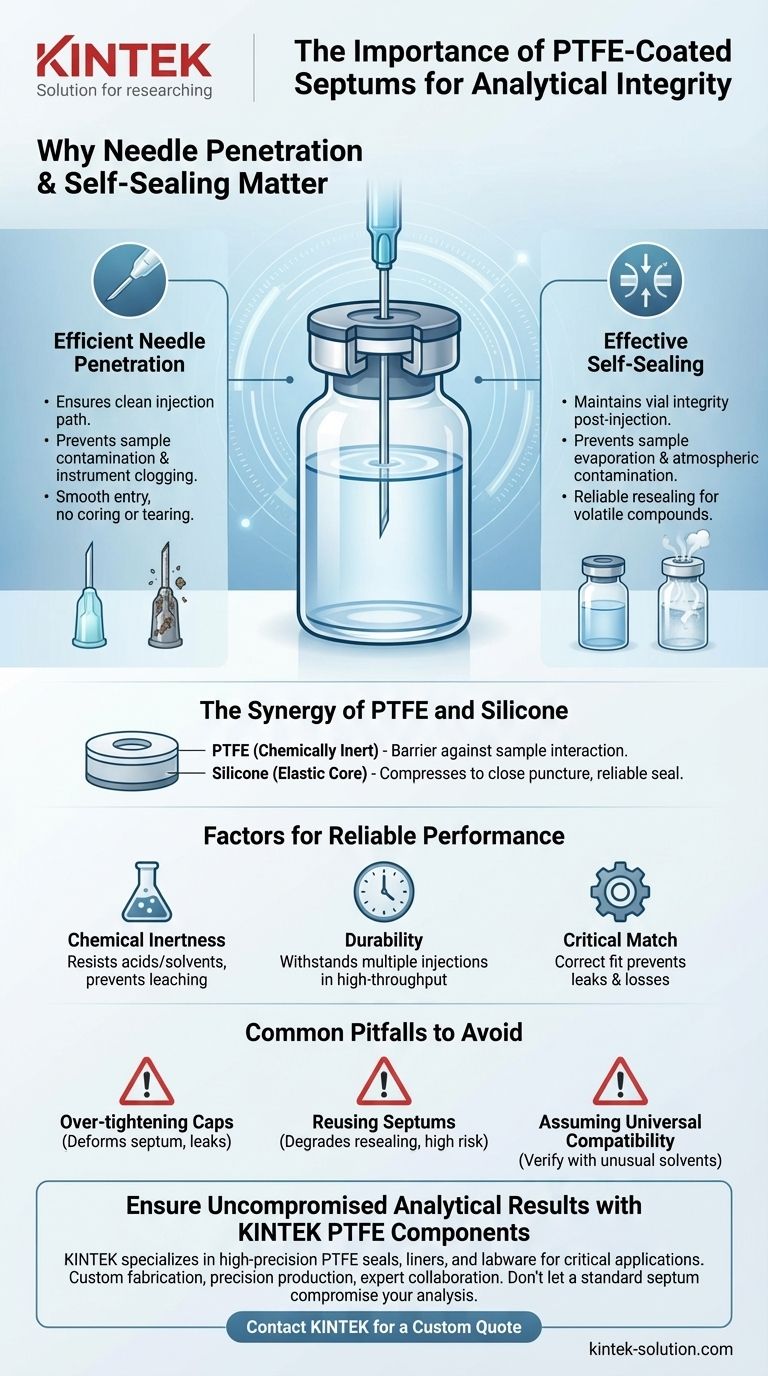

In short, needle penetration and self-sealing properties are critical for two reasons. Efficient needle penetration ensures a clean, smooth injection that does not damage the needle or contaminate the sample with septum debris. Effective self-sealing is essential for maintaining a perfect seal after the needle is withdrawn, preventing sample evaporation and protecting the analysis from atmospheric contamination.

The quality of a septum is not just about its physical components; it is the foundation of sample integrity. Flawless needle penetration and resealing are the two pillars that ensure your analytical results are accurate, reproducible, and free from external interference.

The Septum's Role in Analytical Precision

A vial septum is more than just a lid; it is an active component in the analytical process. Its primary function is to create a barrier that can be temporarily and cleanly breached for sample injection, then perfectly resealed.

Ensuring a Clean Injection Path

Smooth needle penetration is the first step in a successful analysis. The septum must be designed to allow the needle to pass through with minimal force and without being cored or torn.

When a septum is punctured, it should not shed particles into the vial. This debris can contaminate the sample or even clog the narrow tubing of an autosampler or chromatography system, leading to failed runs and instrument downtime.

Preventing Sample Loss and Contamination

Once the needle is removed, the septum's ability to self-seal is paramount. This property is crucial for maintaining the integrity of the vial's contents until the analysis is complete.

For volatile compounds, even a microscopic leak can lead to sample loss through evaporation, altering the sample's concentration and compromising the accuracy of the results. A proper seal also prevents air from entering the vial, which could oxidize sensitive samples.

The Synergy of PTFE and Silicone

The common PTFE/silicone combination is engineered to meet these demands. PTFE (polytetrafluoroethylene) provides a chemically inert barrier that faces the sample, preventing any interaction or leaching.

The silicone layer behind the PTFE provides the elasticity. After the needle is withdrawn, the flexible silicone compresses, closing the puncture and ensuring a reliable, long-lasting seal.

Factors That Guarantee Reliable Performance

While penetration and sealing are the main functions, other characteristics work in concert to ensure the septum performs reliably under demanding laboratory conditions.

The Importance of Chemical Inertness

The primary benefit of the PTFE coating is its exceptional chemical resistance. It is virtually inert to acids, bases, and most organic solvents, which is critical for preventing the septum from reacting with or adsorbing components of your sample.

This inertness ensures that the only thing being analyzed is the sample itself, free from contaminants leached from the septum material.

Durability for Multiple Injections

In automated high-throughput environments, a septum may be punctured multiple times. A thicker PTFE coating improves the septum's resistance to damage from repeated injections.

This extends the life of the septum, ensuring consistent performance throughout a long sequence of analyses and reducing the need for frequent replacement.

The Critical Match of Vial and Septum

The most advanced septum will fail if it does not fit the vial correctly. Ensuring compatibility between the septum's size, design, and the specific vial is essential for creating an effective seal from the start.

An incorrect fit can lead to improper sealing, leaks, and evaporative losses before the needle is ever introduced.

Understanding Common Pitfalls

Even with the right septum, user error can compromise results. Awareness of common mistakes is key to maintaining data integrity.

The Risk of Over-tightening Caps

A common error is to over-tighten the vial cap. This can deform the septum, causing it to bulge or extrude. A distorted septum cannot self-seal properly after being punctured, creating a pathway for leaks.

The Problem with Reusing Septums

While tempting, reusing septums for critical analyses is a significant risk. Each puncture creates a potential failure point, and repeated use degrades the material's ability to reseal effectively, dramatically increasing the chance of evaporation or contamination.

Assuming Universal Compatibility

Although PTFE is highly resistant, you should always verify its compatibility with the specific chemicals used in your laboratory. Extreme or unusual solvents can, in rare cases, compromise the septum's integrity.

Making the Right Choice for Your Goal

Selecting a septum should be a deliberate decision based on the specific demands of your analysis.

- If your primary focus is high-throughput analysis: Prioritize a septum with a thicker PTFE coating designed for high puncture tolerance and durability.

- If your primary focus is analyzing highly volatile compounds: The self-sealing capability is your most critical parameter to prevent sample loss and ensure accurate quantification.

- If your primary focus is trace-level analysis: Absolute chemical inertness is non-negotiable to eliminate any risk of sample contamination from the septum.

Ultimately, treating the septum as a critical component of your analytical method is a crucial step in safeguarding the integrity of your results.

Summary Table:

| Property | Importance | Key Benefit |

|---|---|---|

| Needle Penetration | Ensures a clean injection path | Prevents sample contamination and instrument clogging |

| Self-Sealing | Maintains vial integrity post-injection | Prevents sample evaporation and atmospheric contamination |

| Chemical Inertness (PTFE) | Protects sample purity | Ensures accurate, uncontaminated analytical results |

| Durability | Withstands multiple injections | Provides reliable performance in high-throughput environments |

Ensure Uncompromised Analytical Results with KINTEK PTFE Components

Your laboratory's data integrity depends on the quality of every component, down to the vial septum. Flawless needle penetration and perfect self-sealing are non-negotiable for accurate, reproducible results.

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical role that material performance plays in your applications.

We offer:

- Custom Fabrication: From initial prototypes to high-volume production runs, tailored to your exact specifications.

- Precision Production: Components engineered for superior chemical resistance, durability, and reliable performance.

- Expert Collaboration: Work with our team to select or design the ideal PTFE solution for your specific analytical challenges.

Don't let a standard septum compromise your analysis. Contact our experts today to discuss how our PTFE components can enhance your method's reliability and protect your sample integrity.

Contact KINTEK for a Custom Quote

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance