At its core, a PTFE-lined bottle cap is defined by two key factors: its mechanical closure type and the composition of its liner. The primary mechanical types include screw-on, snap-on, crimp, and vented caps, while liner options range from pure PTFE to composite materials like PTFE-faced silicone, each designed for specific sealing and chemical compatibility requirements.

The term "PTFE-lined cap" is not a single product but a system. The optimal choice depends entirely on matching the cap's physical design and the liner's specific properties to the chemical, temperature, and sealing demands of your application.

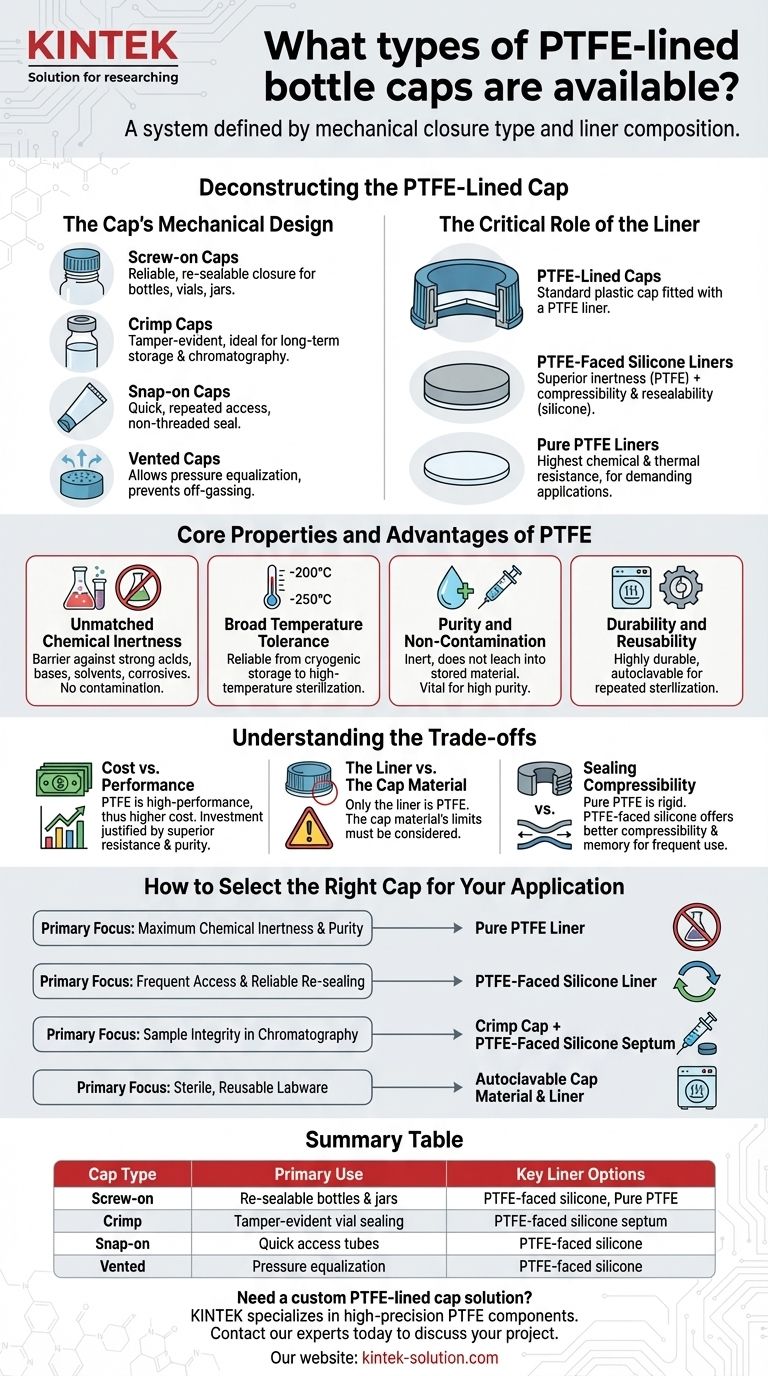

Deconstructing the PTFE-Lined Cap

To select the correct cap, you must understand its two fundamental components: the mechanical design of the cap itself and the material composition of the liner that provides the seal.

The Cap's Mechanical Design

The cap's structure determines how it attaches to a container. The most common types include:

- Screw-on Caps: The most prevalent design, offering a reliable, re-sealable closure for bottles, vials, and jars.

- Crimp Caps: Used extensively for vials in pharmaceutical and laboratory settings, providing a tamper-evident seal that is ideal for long-term sample storage and chromatography.

- Snap-on Caps: Designed for quick, repeated access, often used on tubes and smaller containers where a threaded seal is unnecessary.

- Vented Caps: A specialized design that allows for pressure equalization, critical when storing substances that may off-gas.

The Critical Role of the Liner

The liner is the disc that sits inside the cap and makes direct contact with the container's rim. This is where the benefits of PTFE are realized.

- PTFE-Lined Caps: This typically means a standard plastic cap (like polypropylene) is fitted with a separate liner that has a PTFE layer.

- PTFE-Faced Silicone Liners: This is a highly common and effective composite. It combines the superior chemical inertness of a thin PTFE layer with the compressibility and elasticity of a silicone backing, ensuring an excellent reseal after repeated punctures or openings.

- Pure PTFE Liners: For the most demanding applications, a solid PTFE liner offers the highest level of chemical and thermal resistance, though it is less compressible than composite liners.

Core Properties and Advantages of PTFE

The decision to use a PTFE-lined cap is driven by the material's unique and powerful properties, which are essential for protecting sensitive or aggressive contents.

Unmatched Chemical Inertness

PTFE is famously non-reactive. It provides an exceptional barrier against strong acids, bases, solvents, and nearly all corrosive chemicals, ensuring that the container's contents are not contaminated and the cap itself does not degrade.

Broad Temperature Tolerance

PTFE liners perform reliably across an extreme temperature range, typically from -200°C to +250°C. This makes them suitable for applications ranging from cryogenic storage to high-temperature sterilization.

Purity and Non-Contamination

Because PTFE is inert, it does not leach substances into the stored material. This property is non-negotiable in pharmaceutical, high-purity chemical, and environmental sampling applications where sample integrity is paramount.

Durability and Reusability

These caps are designed for long-term use. Both the cap and the PTFE liner are highly durable and resistant to wear. Crucially, they are autoclavable, allowing for repeated sterilization and reuse without compromising performance.

Understanding the Trade-offs

While highly effective, PTFE-lined caps are not a universal solution. Understanding their limitations is key to proper selection.

Cost vs. Performance

PTFE is a high-performance polymer, and its cost reflects that. Caps with PTFE liners are typically more expensive than those with simpler liners like LDPE or foam. The investment is justified by the need for superior chemical resistance or purity.

The Liner vs. The Cap Material

It is critical to remember that in a "PTFE-lined cap," only the liner is PTFE. The cap itself is usually polypropylene or another plastic. This means the cap's material has its own, more limited, chemical and temperature tolerances that must be considered for the overall application.

Sealing Compressibility

A solid, pure PTFE liner is relatively rigid. While it provides a tight seal, a PTFE-faced silicone liner offers better compressibility and "memory," making it a superior choice for applications requiring frequent opening or sample extraction via a syringe.

How to Select the Right Cap for Your Application

Your choice should be guided by the specific demands of your work.

- If your primary focus is maximum chemical inertness and purity: Choose a cap with a solid, pure PTFE liner for storing aggressive reagents or high-purity standards.

- If your primary focus is frequent access and reliable re-sealing: A PTFE-faced silicone liner provides the ideal balance of chemical resistance and the elastic sealing properties of silicone.

- If your primary focus is sample integrity in chromatography: Select a crimp-style vial cap with a PTFE-faced silicone septum designed for clean needle penetration.

- If your primary focus is sterile, reusable labware: Confirm that both the cap material (e.g., polypropylene) and the liner are certified as autoclavable for your sterilization process.

By matching the cap's design and liner material to your specific requirements, you ensure the ultimate protection and integrity of your materials.

Summary Table:

| Cap Type | Primary Use | Key Liner Options |

|---|---|---|

| Screw-on | Re-sealable bottles & jars | PTFE-faced silicone, Pure PTFE |

| Crimp | Tamper-evident vial sealing | PTFE-faced silicone septum |

| Snap-on | Quick access tubes | PTFE-faced silicone |

| Vented | Pressure equalization | PTFE-faced silicone |

Need a custom PTFE-lined cap solution? KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders to meet your exact chemical compatibility, temperature, and sealing requirements. Contact our experts today to discuss your project and ensure ultimate material integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications