In the modern laboratory, PTFE syringe filters are indispensable because of their exceptional chemical resilience and thermal stability. This unique combination allows them to handle a vast range of aggressive solvents and extreme temperatures without degrading, making them a versatile and reliable tool for ensuring the accuracy of complex analyses.

The true value of a PTFE filter lies not just in its durability, but in its chemical inertness. This quality is the ultimate safeguard for your results, preventing filter-induced sample contamination and protecting sensitive analytical instruments from damaging particulates.

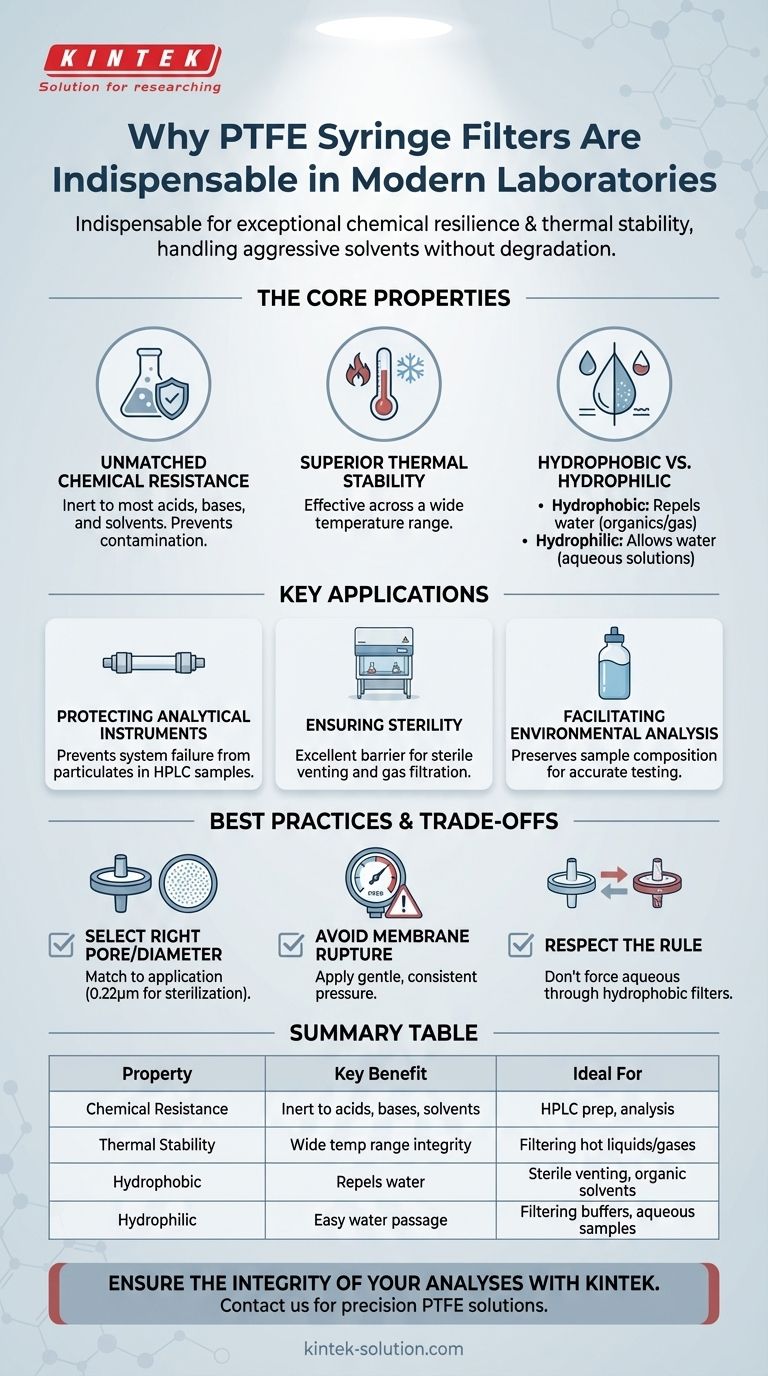

The Core Properties of PTFE Filters

To understand why PTFE (polytetrafluoroethylene) is so essential, we must look at its fundamental characteristics. These properties directly translate into higher quality data and more reliable experimental outcomes.

Unmatched Chemical Resistance

PTFE is virtually inert to most chemicals, including strong acids, bases, and aggressive organic solvents. This means the filter will not break down, swell, or leach extractables into your sample filtrate.

This is critical in applications like chromatography, where even trace contaminants can obscure results or damage expensive equipment.

Superior Thermal Stability

These filters operate effectively across a very wide temperature range. This makes them suitable for applications that involve filtering hot liquids or gases without compromising the integrity of the filter membrane.

The Critical Distinction: Hydrophobic vs. Hydrophilic

The versatility of PTFE is greatly enhanced by the availability of two distinct types, each suited for different liquids.

Hydrophobic PTFE is the standard form and naturally repels water. It is the ideal choice for filtering non-aqueous organic solvents, as well as for sterile air and gas filtration, as it prevents moisture from passing through.

Hydrophilic PTFE is a treated version of the membrane that readily allows water to pass. This makes it perfect for filtering aqueous solutions, buffers, and mixed solvents without the high backpressure or pre-wetting steps required by hydrophobic filters.

Key Applications Across Scientific Disciplines

The robust properties of PTFE filters make them a critical component in workflows ranging from pharmaceutical development to environmental science.

Protecting Analytical Instruments

In High-Performance Liquid Chromatography (HPLC), unfiltered samples are a primary cause of system failure. Particulates can easily clog the narrow tubing and expensive columns.

Using a PTFE syringe filter to clarify samples containing organic solvents is a simple, non-negotiable step to protect the instrument and ensure reproducible results.

Ensuring Sterility in Biological Workflows

The hydrophobic nature of standard PTFE makes it an excellent barrier against aqueous aerosols. This property is leveraged for sterile venting of containers or bioreactors and for filtering gases to prevent microbial contamination in molecular biology and cell culture labs.

Facilitating Environmental Analysis

When analyzing water or air samples for pollutants, the samples can contain a wide array of unknown and potentially aggressive chemicals.

PTFE’s chemical inertness ensures that the filter itself does not react with or add contaminants to the sample, preserving the original composition for accurate testing.

Understanding the Trade-offs and Best Practices

While highly effective, using PTFE filters correctly is key to maximizing their benefits and avoiding common experimental errors.

Select the Right Pore Size and Diameter

Filter choice must match the application. A smaller pore size (e.g., 0.22 µm) is needed for sterilization, while a larger pore size (e.g., 0.45 µm) is sufficient for general particulate removal. The filter diameter should correspond to your sample volume to ensure efficient filtration without excessive clogging.

Avoid Membrane Rupture

Always apply gentle, consistent pressure to the syringe plunger. A sudden application of high pressure can build up too quickly and burst the filter membrane, contaminating your sample and ruining the procedure.

Respect the Hydrophobic/Hydrophilic Rule

Attempting to force an aqueous solution through a hydrophobic PTFE filter will result in extremely high backpressure and little to no flow. Conversely, while a hydrophilic filter can handle some organic solvents, it may not be as robust as a hydrophobic one for highly aggressive chemicals.

Making the Right Choice for Your Experiment

Choosing the correct filter is a simple decision that has a significant impact on your results.

- If your primary focus is preparing HPLC samples in organic solvents: A hydrophobic PTFE filter is the industry standard for removing particulates and protecting your column.

- If your primary focus is filtering aqueous solutions, buffers, or protein samples: A hydrophilic PTFE filter provides the best performance and flow rates without requiring pre-wetting.

- If your primary focus is sterile venting or gas filtration: The water-repellent nature of a hydrophobic PTFE filter is essential for blocking aqueous aerosols while allowing gases to pass freely.

Ultimately, selecting the correct PTFE filter is a foundational step in safeguarding the integrity of your experiment from start to finish.

Summary Table:

| Property | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to acids, bases, solvents; prevents sample contamination | HPLC sample prep, environmental analysis |

| Thermal Stability | Maintains integrity across a wide temperature range | Filtering hot liquids/gases |

| Hydrophobic | Repels water; ideal for organic solvents and gas filtration | Sterile venting, organic solvent clarification |

| Hydrophilic | Treated for easy water passage; low backpressure with aqueous solutions | Filtering buffers, aqueous samples, proteins |

Ensure the integrity of your most critical analyses with precision PTFE filters from KINTEK.

Our PTFE components—including seals, liners, labware, and custom-fabricated syringe filters—are engineered for the demanding environments of semiconductor, medical, laboratory, and industrial applications. We prioritize precision production to deliver reliable performance with aggressive solvents and extreme temperatures, protecting your sensitive instruments and ensuring accurate results.

Whether you need standard options or custom fabrication from prototypes to high-volume orders, KINTEK provides the chemical inertness and durability your lab requires.

Contact us today to discuss your specific filtration needs and discover how our PTFE solutions can enhance your workflow.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications