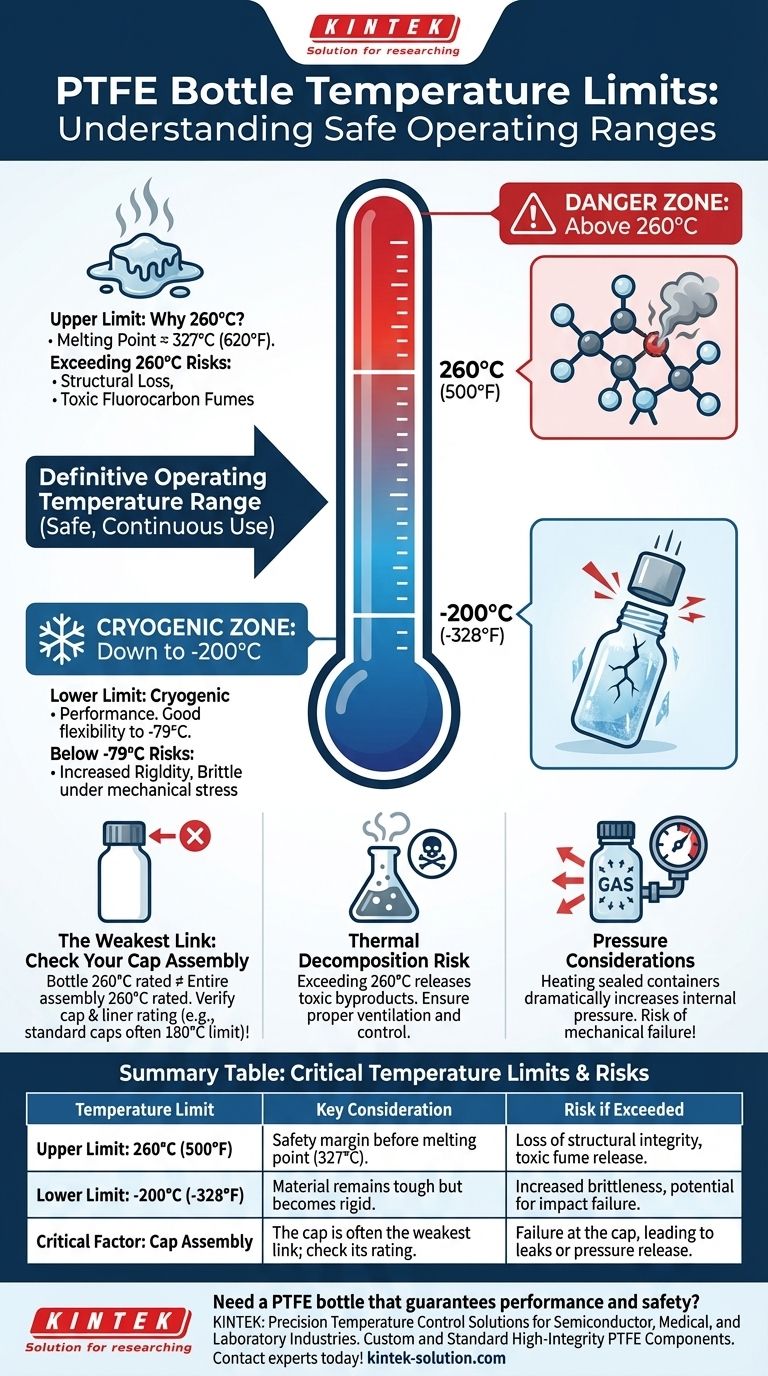

The definitive operating temperature range for a solid Polytetrafluoroethylene (PTFE) bottle is from -200°C to 260°C (-328°F to 500°F). This wide range makes it suitable for both cryogenic storage and high-temperature laboratory procedures. However, this range represents the safe, continuous-use limit for the material, not its absolute failure point.

Understanding the difference between a material's safe operating temperature and its physical melting point is critical. The entire assembly, including the cap, dictates the true thermal limit of your container and is the key to ensuring both safety and experimental integrity.

Deconstructing the Temperature Limits

The stated range of -200°C to 260°C is not arbitrary. It is defined by the physical and chemical behavior of the PTFE polymer at thermal extremes.

The Upper Limit: Why 260°C?

The melting point of PTFE is approximately 327°C (620°F). However, its recommended maximum operating temperature is set lower, at 260°C (500°F), to provide a critical safety margin.

Above this temperature, PTFE begins to soften and lose its structural integrity well before it melts. More importantly, significant thermal decomposition can occur, potentially releasing hazardous fluorocarbon fumes.

Adhering to the 260°C limit ensures the bottle remains structurally sound and chemically inert, preventing contamination of its contents or the creation of a hazardous environment.

The Lower Limit: Cryogenic Performance

PTFE maintains remarkable strength and toughness at extremely low temperatures. While the typical bottle is rated for -200°C (-328°F), the material itself can perform at temperatures approaching absolute zero.

Even so, be aware that material properties change. PTFE maintains good flexibility down to approximately -79°C (-110°F). Below this, it becomes progressively more rigid, which should be considered if mechanical stress is a factor in your application.

Understanding the Trade-offs and Critical Risks

A bottle's material rating is only one part of the equation. In practice, the entire system must be evaluated to determine the true operational limits.

The "Weakest Link" Principle: Check Your Cap

The most common point of failure is not the bottle itself, but the cap or its liner. A bottle rated for 260°C is useless if its cap is only rated for 180°C.

Always verify the temperature rating of the entire assembly. Standard PTFE-lined caps often have a much lower range (e.g., -40°C to 180°C) than the bottle, while specialized caps may match the bottle's full -200°C to +250°C capability.

The Risk of Thermal Decomposition

Exceeding the 260°C safe operating temperature is not a soft limit. Overheating PTFE poses a real risk, as its decomposition byproducts are toxic. Proper temperature control and ventilation are paramount when working near the upper temperature limit.

Pressure Considerations in Sealed Containers

Remember that heating any sealed or semi-sealed container will dramatically increase internal pressure. This pressure can cause mechanical failure of the bottle or cap long before the material's thermal limit is reached. Always account for pressure changes when heating substances in a PTFE bottle.

Making the Right Choice for Your Application

To ensure safety and accuracy, match the equipment's capabilities to your specific procedural needs.

- If your primary focus is high-temperature work (approaching 260°C): Verify that both the bottle and its specific cap are rated for your target temperature and ensure adequate ventilation.

- If your primary focus is cryogenic storage (down to -200°C): Confirm the bottle's rating and handle it with care, as the material will be more rigid and less impact-resistant than at room temperature.

- If your procedure involves sealing the container: Always calculate the potential pressure increase from heating and ensure your application remains safely within the mechanical limits of the bottle and cap.

By respecting these established limits, you ensure the safety, accuracy, and integrity of your work.

Summary Table:

| Temperature Limit | Key Consideration | Risk if Exceeded |

|---|---|---|

| Upper Limit: 260°C (500°F) | Safety margin before melting point (327°C). | Loss of structural integrity, toxic fume release. |

| Lower Limit: -200°C (-328°F) | Material remains tough but becomes rigid. | Increased brittleness, potential for impact failure. |

| Critical Factor: Cap Assembly | The cap is often the weakest link; check its rating. | Failure at the cap, leading to leaks or pressure release. |

Need a PTFE bottle that guarantees performance and safety at your required temperatures?

At KINTEK, we understand that precise temperature control is non-negotiable in the semiconductor, medical, and laboratory industries. We manufacture high-integrity PTFE components—including bottles, seals, liners, and labware—with a focus on precision and material purity. Whether you need a standard solution for cryogenic storage or a custom-fabricated bottle and cap assembly rated for high-temperature applications up to 260°C, we can deliver from prototype to high-volume orders.

Ensure your process integrity and operator safety. Contact our experts today to discuss your specific thermal and chemical resistance requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How is Teflon used in laboratory settings? Essential for Chemical Resistance and Purity

- What are PTFE stirring shafts and what styles are available? Select the Right Impeller for Your Lab

- Why are PTFE/silicone septums considered essential in chromatographic analysis? Ensure Data Integrity and Purity

- Why are PTFE filters advantageous for gravimetric analysis? Achieve Unmatched Accuracy and Precision

- How can PTFE/silicone septa potentially cause contamination in laboratory analyses? Ensure Sample Integrity with the Right Septa

- How are PTFE stirrers and shafts typically constructed for industrial use? Choose the Right Method for Your Process

- What additional advantages does PTFE offer for laboratory use? Maximize Purity and Reliability

- How do PTFE and silicone septa compare in terms of temperature range? Choosing the Right Septa for Your Lab