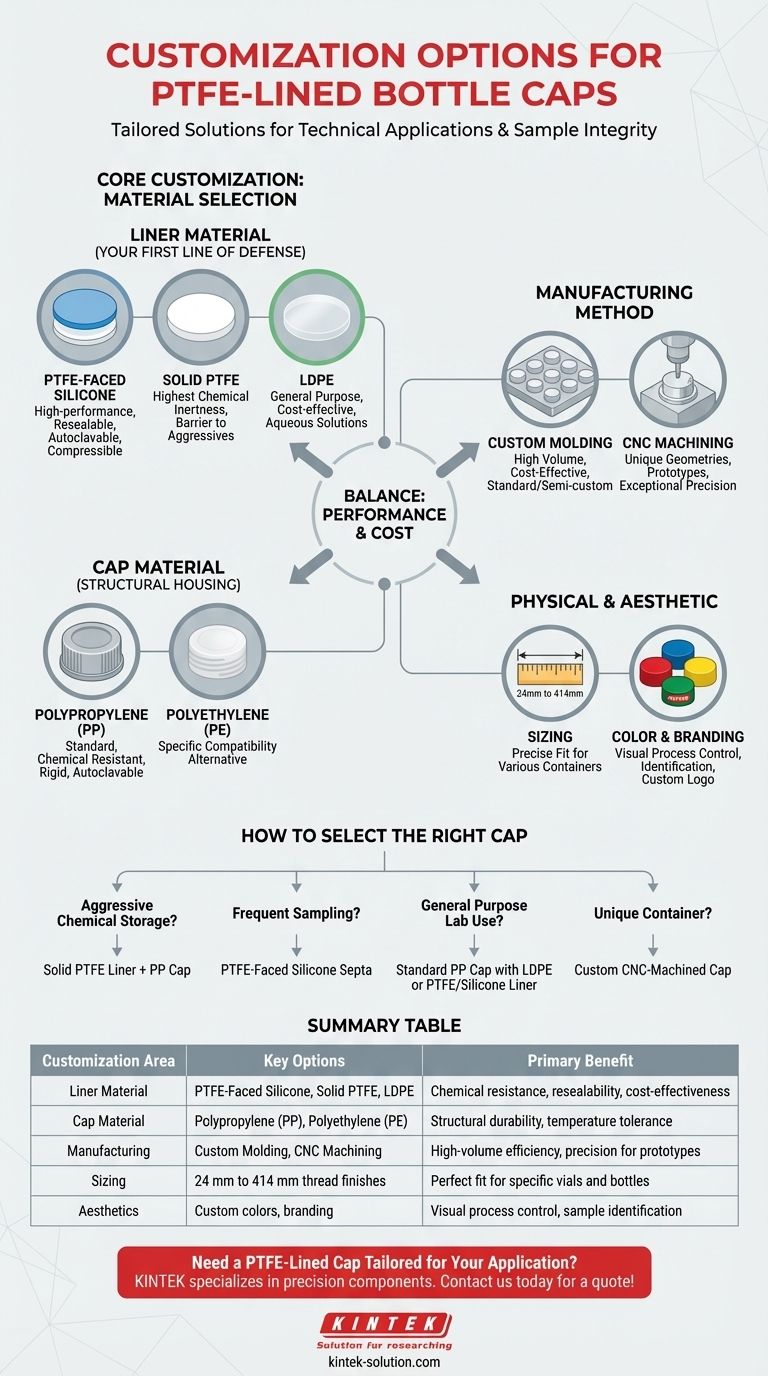

The customization options for PTFE-lined bottle caps are extensive, extending far beyond simple sizing. You can specify the liner and cap materials, the manufacturing method (molded or machined), physical dimensions, and even aesthetic elements like color and branding to create a cap perfectly suited for a specific technical application.

The most critical customization is not the cap's size or color, but the selection of its liner and cap material. These choices directly determine the cap's chemical resistance, temperature tolerance, and sealing performance, which are essential for ensuring sample integrity and safety.

Core Customization: Matching Material to Your Application

The primary function of a PTFE-lined cap is to provide an inert, highly resistant seal. Therefore, the most important customizations involve the materials that come into contact with your substance and its environment.

The Liner: Your First Line of Defense

The liner is the disc inside the cap that forms the seal against the container's rim. Its material is paramount for chemical compatibility.

- PTFE-Faced Silicone: This is a common high-performance option. A silicone core provides excellent compressibility for a tight seal and repeated resealing after needle punctures, while the thin PTFE layer offers a chemically inert contact surface. It is also ideal for repeated autoclaving.

- Solid PTFE: For applications requiring the absolute highest level of chemical inertness and resistance, a solid PTFE liner is the choice. It provides an unparalleled barrier against aggressive acids, solvents, and corrosives.

- LDPE (Low-Density Polyethylene): This liner is a more general-purpose, cost-effective option suitable for less aggressive chemicals and aqueous solutions where the extreme properties of PTFE are not required.

The Cap: Balancing Durability and Compatibility

The cap itself provides the structural housing for the liner and engages with the container's threads.

- Polypropylene (PP): This is the standard material for high-performance caps. It offers a good balance of chemical resistance, rigidity, and temperature tolerance, and it is fully autoclavable.

- Polyethylene (PE): In certain situations, polyethylene may be specified as an alternative cap material, often chosen for its compatibility with specific chemicals where PP might be less suitable.

Manufacturing Method: Molded vs. CNC Machined

The production method affects the cap's precision and is chosen based on volume and design complexity.

- Custom Molding: Injection molding is used for high-volume production of standard or semi-custom cap designs. It is the most cost-effective method for large quantities.

- CNC Machining: For unique geometries, prototypes, or low-volume production runs requiring exceptional precision, caps can be custom-machined from a solid block of PTFE or other polymers.

Physical and Aesthetic Customizations

While secondary to material selection, physical and aesthetic options are crucial for process control and usability.

Sizing and Dimensions

Caps are highly customizable in size to fit a wide range of vials, bottles, and containers. Sizes commonly range from 24 mm to 414 mm thread finishes, ensuring a precise match for your specific container.

Color and Branding

Caps can be produced in custom colors. This is frequently used for visual process control, allowing laboratory or industrial staff to quickly identify container contents by color-coding caps for different chemicals, samples, or production stages. Custom branding can also be added.

Understanding the Trade-offs

Choosing the right customization requires balancing performance needs with practical constraints.

Cost vs. Performance

A standard, injection-molded polypropylene cap with an LDPE liner is a highly economical solution. Conversely, a custom-sized, CNC-machined solid PTFE cap offers ultimate performance but at a significantly higher cost per unit.

Sealing Integrity vs. Reusability

A PTFE-faced silicone liner (septa) is designed for repeated punctures and high reusability. However, for long-term storage of volatile solvents, a solid, non-pierceable liner may provide a more robust vapor seal over time.

Chemical Resistance vs. Physical Properties

While PTFE offers supreme chemical resistance, other materials like polypropylene provide the structural rigidity needed for a cap. This is why multi-material construction (a PP cap with a PTFE liner) is the most common and effective solution.

How to Select the Right Cap

Your choice should be dictated entirely by your application's demands.

- If your primary focus is aggressive chemical storage: Prioritize a solid PTFE liner within a polypropylene cap to ensure maximum chemical inertness and a robust seal.

- If your primary focus is frequent sampling or injection: Choose a PTFE-faced silicone septa for its superior resealability and durability through repeated autoclaving cycles.

- If your primary focus is general-purpose lab use: A standard polypropylene cap with an LDPE or PTFE/silicone liner often provides the best balance of performance and cost.

- If your primary focus is a unique container or prototype: Consider a custom CNC-machined cap to meet precise dimensional requirements that are unavailable with standard molded options.

By aligning your material and design choices with your specific application, you ensure the safety, purity, and integrity of your contained substances.

Summary Table:

| Customization Area | Key Options | Primary Benefit |

|---|---|---|

| Liner Material | PTFE-Faced Silicone, Solid PTFE, LDPE | Chemical resistance, resealability, cost-effectiveness |

| Cap Material | Polypropylene (PP), Polyethylene (PE) | Structural durability, temperature tolerance |

| Manufacturing | Custom Molding, CNC Machining | High-volume efficiency, precision for prototypes |

| Sizing | 24 mm to 414 mm thread finishes | Perfect fit for specific vials and bottles |

| Aesthetics | Custom colors, branding | Visual process control, sample identification |

Need a PTFE-Lined Cap Tailored for Your Application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom bottle caps, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a high-volume molded solution or a custom-machined prototype, we ensure your cap delivers the exact chemical resistance, temperature tolerance, and sealing performance your process demands.

Contact us today to discuss your requirements and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance