Contrary to common assumption, pure PTFE (Polytetrafluoroethylene) is an inherently opaque white material. The "transparency" feature in lab vials is typically achieved not by PTFE itself, but by using a related transparent fluoropolymer like PFA (Perfluoroalkoxy alkane) for the vial body or as a liner. This modification provides essential visual access to the sample while retaining most of PTFE's desirable chemical properties.

The core issue is balancing the absolute chemical inertness of opaque PTFE with the practical laboratory need for visual sample inspection. This balance is most often struck by using PFA, a transparent cousin of PTFE, for the vial itself.

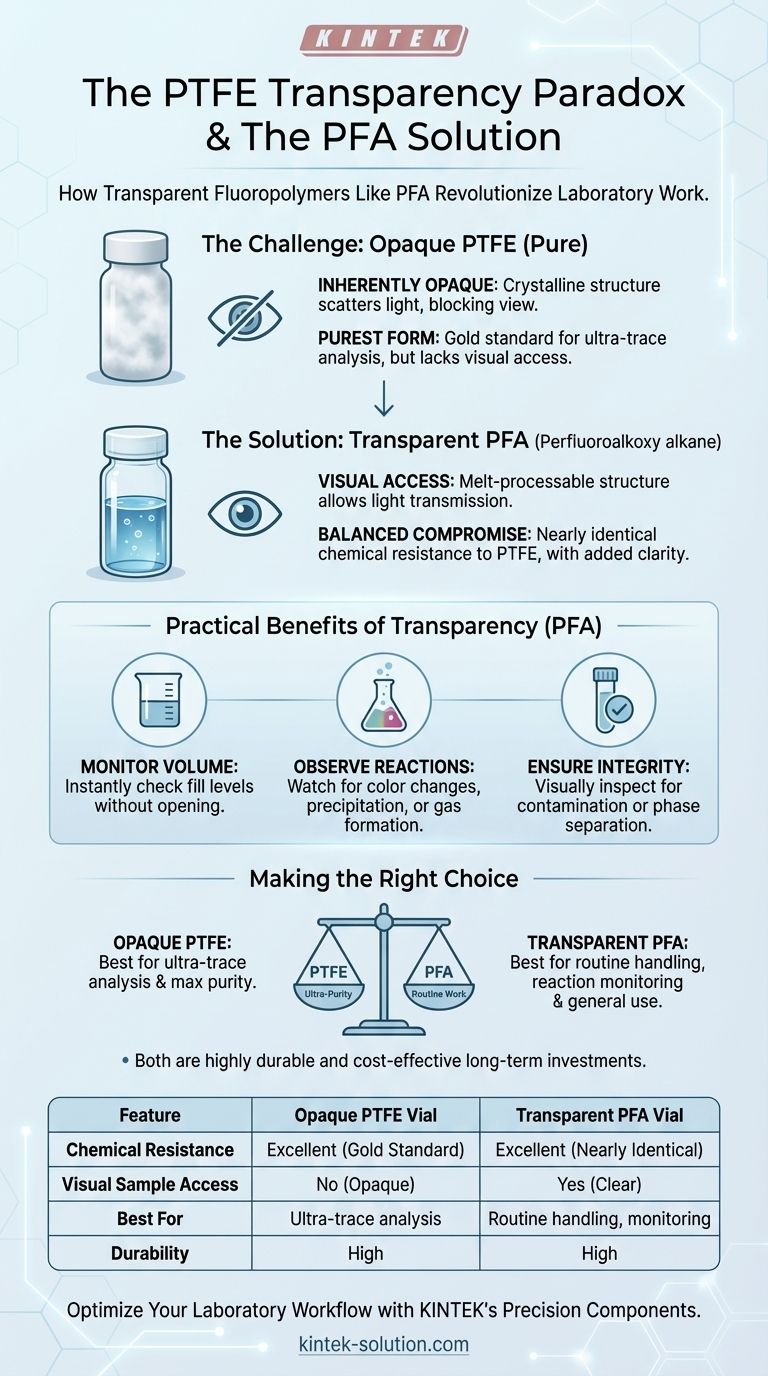

The Challenge: Purity vs. Practicality

In high-purity and critical laboratory work, the material a sample touches is paramount. PTFE became the gold standard for its unmatched chemical resistance and low reactivity, but its natural opacity presents a significant operational drawback.

The Opaque Nature of PTFE

Pure, sintered PTFE is opaque because of its crystalline molecular structure, which scatters light. This means you cannot see the sample volume, check for phase separation, or observe color changes without opening the container, which increases the risk of contamination.

The Need for Visual Confirmation

In a busy lab environment, visual access is not a luxury; it is a critical safety and efficiency feature. Technicians need to quickly confirm fill levels, identify samples at a glance, and monitor reactions or solubility in real time. Working "blind" with an opaque vial is inefficient and prone to error.

The Solution: Transparent Fluoropolymers

To solve this dilemma, manufacturers use fluoropolymers that share PTFE's core chemical backbone but have a modified structure that allows for light transmission.

PFA: The Transparent Workhorse

The most common material used for "transparent PTFE" vials is actually PFA (Perfluoroalkoxy alkane). PFA offers a chemical resistance profile and temperature tolerance that is nearly identical to PTFE. However, because it is melt-processable, it can be injection molded into a smooth, glass-clear container.

Practical Benefits of Transparency

This transparency allows lab personnel to:

- Monitor Sample Volume: Instantly see how much sample or reagent remains without weighing or opening the vial.

- Observe Reactions: Watch for color changes, precipitation, or gas formation during an experiment.

- Ensure Sample Integrity: Visually check for contamination, degradation, or unexpected phase separation before analysis.

Understanding the Trade-offs

While PFA is an excellent solution, it is crucial to understand the subtle differences when choosing a vial for a specific application.

Opaque PTFE: The Gold Standard for Purity

For the most demanding applications, such as ultra-trace metals analysis, many chemists still prefer pure, opaque PTFE. The logic is that it represents the single, most inert material with no possibility of additives or processing aids that could be present in a molded PFA vial.

PFA: The Balanced Compromise

For the vast majority of lab work, the benefits of PFA's transparency far outweigh any minute theoretical differences in purity. It provides the chemical resistance needed for aggressive acids, bases, and solvents, combined with the practical workflow of a clear container.

Durability and Cost

Both PTFE and PFA are extremely durable materials that resist breakage and do not need to be replaced frequently. This longevity makes them a highly cost-effective choice in the long term compared to glass or less robust plastics, despite a higher initial purchase price.

Making the Right Choice for Your Application

Your choice between opaque PTFE and transparent PFA should be dictated entirely by the specific demands of your experiment.

- If your primary focus is the absolute highest level of chemical purity for ultra-trace analysis: Choose an opaque, virgin PTFE vial to eliminate all possible variables.

- If your primary focus is routine sample handling, storage, and reaction monitoring: Choose a transparent PFA vial for its excellent balance of chemical resistance and visual clarity.

- If your primary focus is long-term durability and cost savings: Both PTFE and PFA are superior investments that will outperform and outlast nearly all other labware materials.

Ultimately, understanding the material science allows you to select the precise tool needed to ensure the integrity and efficiency of your work.

Summary Table:

| Feature | Opaque PTFE Vial | Transparent PFA Vial |

|---|---|---|

| Chemical Resistance | Excellent (Gold Standard) | Excellent (Nearly Identical to PTFE) |

| Visual Sample Access | No | Yes |

| Best For | Ultra-trace analysis, maximum purity | Routine handling, reaction monitoring, general use |

| Durability | High | High |

Optimize your laboratory workflow with precision PTFE and PFA components from KINTEK.

Whether your application demands the absolute purity of opaque PTFE for ultra-trace analysis or the practical visibility of transparent PFA for routine monitoring, KINTEK delivers. We manufacture high-quality, custom-fabricated PTFE and PFA components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

Leverage our expertise in precision production from prototypes to high-volume orders. Ensure sample integrity and boost lab efficiency with components built for durability and chemical resistance.

Contact KINTEK today to discuss your specific needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- What are the different types of Teflon available? A Guide to PTFE, FEP, PFA, and More

- How does PTFE's molecular structure contribute to its non-stick properties? The Science Behind Its Slick Surface

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers