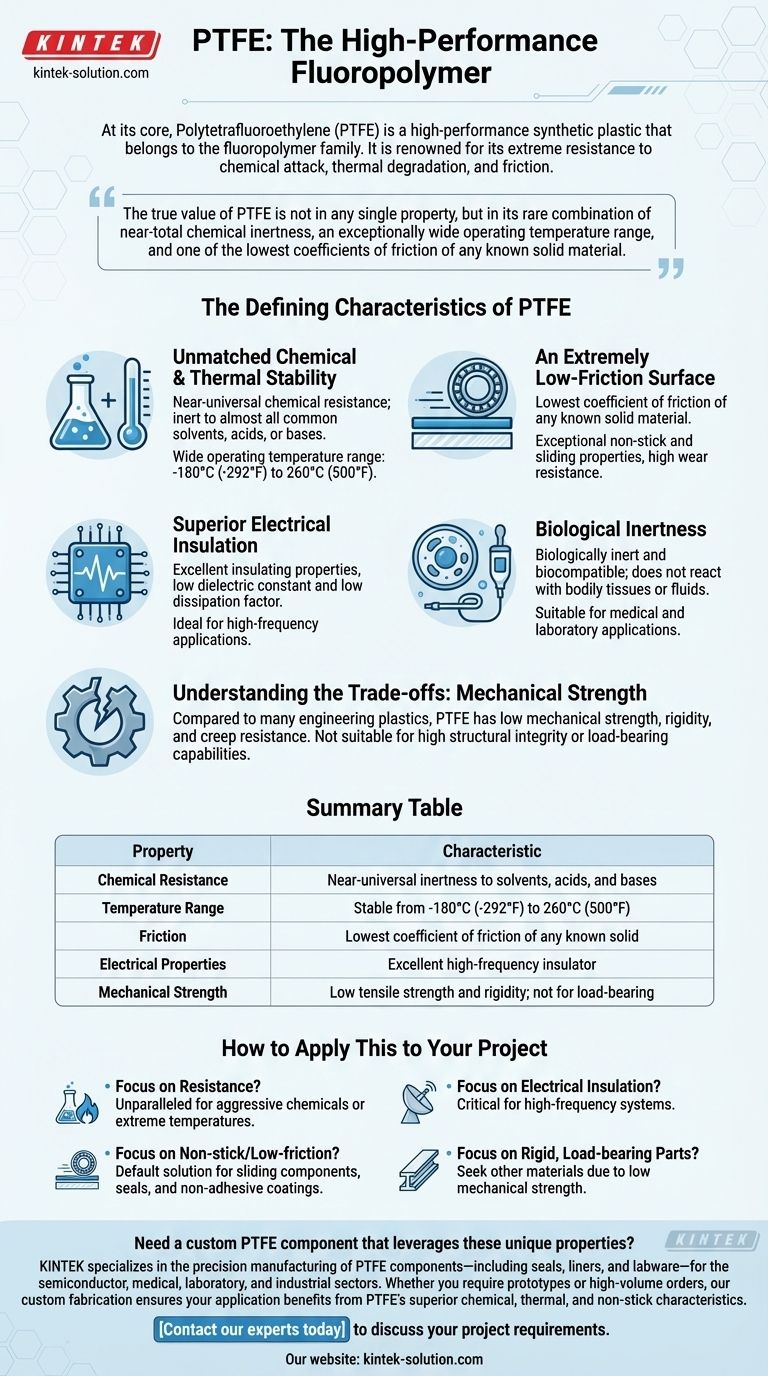

At its core, Polytetrafluoroethylene (PTFE) is a high-performance synthetic plastic that belongs to the fluoropolymer family. It is renowned for its extreme resistance to chemical attack, thermal degradation, and friction, making it one of the most versatile and specialized materials in modern engineering.

The true value of PTFE is not in any single property, but in its rare combination of near-total chemical inertness, an exceptionally wide operating temperature range, and one of the lowest coefficients of friction of any known solid material.

The Defining Characteristics of PTFE

PTFE's unique molecular structure gives it a set of properties that are difficult to find in any other single polymer. Understanding these characteristics explains why it is chosen for such demanding applications.

Unmatched Chemical & Thermal Stability

PTFE exhibits near-universal chemical resistance. It is virtually inert and will not react with almost any common solvent, acid, or base.

This stability extends to temperature. PTFE maintains its properties across a vast working temperature range, from as low as -180°C (-292°F) up to 260°C (500°F).

An Extremely Low-Friction Surface

PTFE has the lowest coefficient of friction of any known solid material. This gives it exceptional non-stick and sliding properties, which is why it is famous as a coating on non-stick cookware.

This low friction also contributes to its high wear resistance, as surfaces can move against it with minimal abrasion.

Superior Electrical Insulation

The material possesses excellent insulating properties. Its low dielectric constant and low dissipation factor make it an ideal choice for high-frequency applications.

This is why it is frequently used in insulators for cables, connectors, and printed circuit boards, especially in radio frequency systems.

Biological Inertness

PTFE is biologically inert and biocompatible, meaning it does not react with bodily tissues or fluids. This property makes it suitable for certain medical and laboratory applications where purity and non-reactivity are critical.

Understanding the Trade-offs: Mechanical Strength

While PTFE's properties are exceptional, it is not the right material for every job. Its primary limitation is a critical factor in its application.

Low Tensile Strength and Rigidity

Compared to many engineering plastics, PTFE has low mechanical strength, rigidity, and creep resistance. It is a relatively soft and flexible material.

This means it is generally unsuitable for applications that require high structural integrity or load-bearing capabilities. It is not designed to be a primary structural component.

Leveraging Strengths Over Weaknesses

Engineers select PTFE for applications that specifically leverage its thermal, chemical, or frictional properties. In these contexts, its low mechanical strength is either irrelevant or can be compensated for by incorporating it into a composite assembly.

How to Apply This to Your Project

Choosing a material requires matching its profile to your primary goal. PTFE is a problem-solver for specific, challenging conditions.

- If your primary focus is resistance to aggressive chemicals or extreme temperatures: PTFE is an unparalleled choice due to its chemical inertness and wide, stable operating range.

- If your primary focus is creating a non-stick, low-friction surface: PTFE's exceptionally low coefficient of friction makes it the default solution for sliding components, seals, and non-adhesive coatings.

- If your primary focus is electrical insulation for high-frequency systems: PTFE's excellent dielectric properties are critical for maintaining signal integrity and preventing loss.

- If your primary focus is building rigid, load-bearing parts: You should seek other materials, as PTFE's low mechanical strength is its most significant limitation.

Ultimately, understanding PTFE is about recognizing its power as a specialized material designed for performance under conditions where most other plastics would fail.

Summary Table:

| Property | Characteristic |

|---|---|

| Chemical Resistance | Near-universal inertness to solvents, acids, and bases |

| Temperature Range | Stable from -180°C (-292°F) to 260°C (500°F) |

| Friction | Lowest coefficient of friction of any known solid |

| Electrical Properties | Excellent high-frequency insulator |

| Mechanical Strength | Low tensile strength and rigidity; not for load-bearing |

Need a custom PTFE component that leverages these unique properties?

KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our custom fabrication ensures your application benefits from PTFE's superior chemical, thermal, and non-stick characteristics.

Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- What precautions should be taken when using Teflon cookware? Essential Safety Tips for Non-Stick Pans

- What chemicals is Teflon resistant to? The Ultimate Guide to PTFE Chemical Inertness

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are common uses of PTFE? Unlock Versatility for Your Industry

- What are the key properties of Teflon (PTFE) that make it suitable for industrial applications?

- Is PTFE safe for use in electrical environments? Achieve Superior Insulation & Reliability

- Which industries commonly use PTFE materials? A Guide to High-Performance Polymer Applications

- How does the molecular structure of PTFE differ from regular plastics? Discover the Power of the Fluorine Sheath