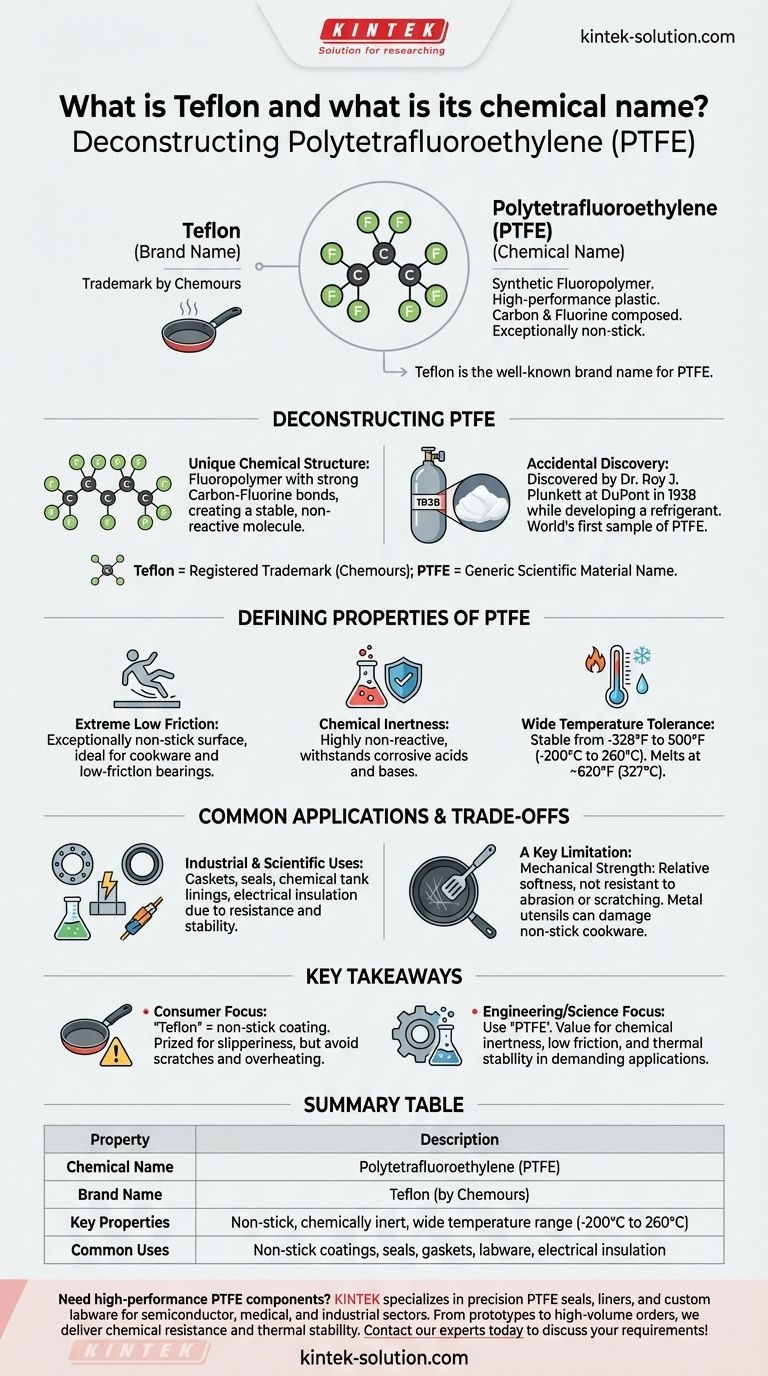

In short, Teflon is the well-known brand name for a synthetic fluoropolymer whose chemical name is Polytetrafluoroethylene, most often abbreviated as PTFE. It is a high-performance plastic composed of carbon and fluorine, renowned for its exceptionally non-stick surface, chemical resistance, and stability across a wide range of temperatures.

While most people know it as the coating on non-stick pans, the name "Teflon" is actually a trademark. The material itself is Polytetrafluoroethylene (PTFE), a unique polymer whose properties make it indispensable in countless industrial and scientific applications.

Deconstructing Polytetrafluoroethylene (PTFE)

A Unique Chemical Structure

Polytetrafluoroethylene is a fluoropolymer, a type of plastic. Its structure consists of a long chain of carbon atoms, where each carbon is bonded to two fluorine atoms.

This strong carbon-fluorine bond is the source of PTFE's remarkable properties. It creates a very stable and non-reactive molecule.

An Accidental Discovery

PTFE was discovered by accident in 1938 by Dr. Roy J. Plunkett at DuPont. While working to develop a new refrigerant, he opened a pressurized gas cylinder that appeared to be empty but still weighed as much as if it were full.

Upon cutting it open, he found it was coated with a waxy, incredibly slippery white solid. This new material was the world's first sample of PTFE, which was later trademarked as Teflon.

"Teflon" is the Brand, "PTFE" is the Material

It is critical to distinguish between the brand name and the chemical name. Teflon is the registered trademark for PTFE, now owned by the company Chemours (a spin-off from DuPont).

PTFE is the generic, scientific name for the material itself. While Teflon is the most famous brand of PTFE, other companies can and do manufacture PTFE under different names.

The Defining Properties of PTFE

The unique chemical makeup of Polytetrafluoroethylene gives it a combination of characteristics that are highly valuable in engineering and manufacturing.

Extreme Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This is what creates its famous "non-stick" quality, making it ideal for cookware and low-friction bearings.

Chemical Inertness

The material is exceptionally non-reactive. It can withstand a vast range of highly corrosive acids and bases without degrading. Only a few substances, like molten alkali metals, are known to affect it.

Wide Temperature Tolerance

PTFE remains stable and functional across an impressively broad temperature spectrum, typically from -328°F to 500°F (-200°C to 260°C). It melts at approximately 600 K (620°F or 327°C).

Common Applications and Trade-offs

While its most famous application is in the kitchen, PTFE's properties make it a workhorse material in demanding industrial environments.

Industrial and Scientific Uses

Because of its chemical resistance and temperature stability, PTFE is widely used for gaskets, seals, linings for pipes and chemical tanks, and electrical insulation.

A Key Limitation: Mechanical Strength

A primary trade-off of PTFE is its relative softness. As a material, it is not very resistant to abrasion or scratching. This is why metal utensils can easily damage the non-stick coating on a frying pan.

Key Takeaways for Practical Understanding

- If your primary focus is consumer products: Recognize that "Teflon" refers to the non-stick PTFE coating on items like cookware, which is prized for its slipperiness but can be damaged by scratches and overheating.

- If your primary focus is engineering or science: Use the chemical name Polytetrafluoroethylene (PTFE) and value it for its unique combination of chemical inertness, low friction, and thermal stability in demanding applications.

Understanding the distinction between the Teflon brand and the PTFE material is the key to appreciating its role in both everyday life and advanced engineering.

Summary Table:

| Property | Description |

|---|---|

| Chemical Name | Polytetrafluoroethylene (PTFE) |

| Brand Name | Teflon (by Chemours) |

| Key Properties | Non-stick, chemically inert, wide temperature range (-200°C to 260°C) |

| Common Uses | Non-stick coatings, seals, gaskets, labware, electrical insulation |

Need high-performance PTFE components for your application? KINTEK specializes in manufacturing precision PTFE seals, liners, and custom labware for the semiconductor, medical, and industrial sectors. From prototypes to high-volume orders, we deliver the chemical resistance and thermal stability your project demands. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries