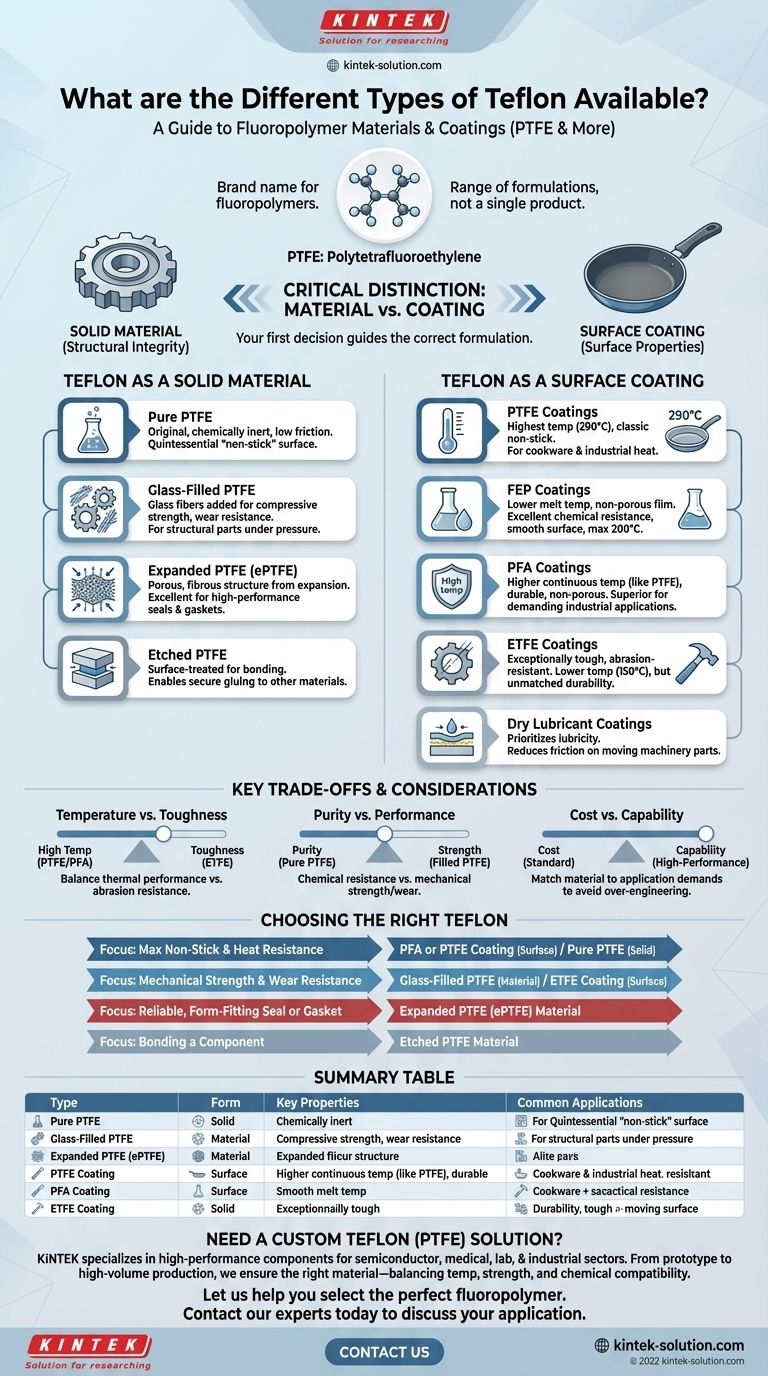

When we talk about "Teflon," we are referring to the brand name for a family of fluoropolymer plastics, the most famous of which is Polytetrafluoroethylene (PTFE). This material isn't a single product but a range of formulations available as either solid materials for manufacturing components or as liquid coatings applied to surfaces. The main types are distinguished by their chemical composition and the fillers used, which alter their mechanical properties, temperature resistance, and ideal applications.

The critical distinction is not just which fluoropolymer to choose, but how it will be used. Your first decision is whether you need Teflon as a solid, structural material for a part or as a thin coating for a surface, as this will guide you to the correct formulation.

Understanding Teflon: Materials vs. Coatings

Before selecting a type of Teflon, you must identify your core need. Are you machining a part, like a bushing or a seal, or are you applying a non-stick layer to a metal substrate?

This distinction is the most important factor in navigating the different options available. Solid materials are chosen for their structural integrity, while coatings are chosen for their surface properties.

Teflon as a Solid Material

When you need to create a physical component, you will use a solid form of Teflon, often supplied in rods, sheets, or tubes. The primary variations involve adding fillers to pure PTFE to enhance specific properties.

Pure PTFE

This is the original formulation known for its exceptional chemical inertness and extremely low coefficient of friction. It provides the quintessential "non-stick" surface.

Glass-Filled PTFE

By adding glass fibers to the PTFE base, the material gains significant compressive strength and wear resistance. This makes it ideal for structural parts that need to withstand pressure without deforming.

Expanded PTFE (ePTFE)

This variant is created by expanding PTFE, which introduces a porous, fibrous structure. This unique property makes it exceptionally good for creating high-performance seals and gaskets.

Etched PTFE

One of PTFE's greatest strengths—its non-reactivity—also makes it nearly impossible to bond with adhesives. Etched PTFE is surface-treated on one side to allow it to be securely glued to other materials.

Teflon as a Surface Coating

Coatings are applied as a liquid and then cured with heat to form a solid film on a substrate. These are chosen when you need to impart Teflon's properties onto another object.

PTFE Coatings

This is the most well-known coating, offering the highest operating temperature (up to 290°C) and the classic non-stick performance. It's often used in cookware and industrial applications requiring heat resistance.

FEP (Fluorinated Ethylene Propylene) Coatings

FEP melts at a lower temperature than PTFE and forms a non-porous film. This provides excellent chemical resistance and a very smooth surface, but its maximum use temperature is lower, around 200°C.

PFA (Perfluoroalkoxy) Coatings

PFA offers the benefits of FEP but with a higher continuous use temperature, similar to PTFE. It is tougher and more durable than PTFE, making it a superior choice for demanding industrial applications.

ETFE (Ethylene Tetrafluoroethylene) Coatings

Often sold under the brand name Tefzel, ETFE is an exceptionally tough and abrasion-resistant coating. While its temperature resistance is lower (around 150°C), its durability is unmatched among fluoropolymer coatings.

Dry Lubricant Coatings

These are specialized coatings that prioritize lubricity over other factors. They use PTFE and other binders to create a slick surface ideal for reducing friction on moving parts in machinery.

Key Trade-offs and Considerations

Choosing the right Teflon type involves balancing competing properties. Understanding these trade-offs is crucial for a successful application.

Temperature vs. Toughness

Generally, coatings with the highest temperature resistance, like PTFE and PFA, are not as mechanically tough as options like ETFE. You must decide whether thermal performance or abrasion resistance is your primary concern.

Purity vs. Performance

Pure PTFE offers the best chemical resistance and lubricity. However, adding fillers like glass drastically improves mechanical strength and wear resistance, which may be necessary for structural components.

Cost vs. Capability

High-performance variants like PFA coatings or specialized materials like expanded PTFE carry a higher cost. It's essential to match the material's capability to the actual demands of the application to avoid over-engineering.

Choosing the Right Teflon for Your Application

Your final decision should be based on the primary goal of your project.

- If your primary focus is maximum non-stick performance and heat resistance: A PFA or PTFE coating is your best choice for surfaces, while pure PTFE is ideal for solid parts.

- If your primary focus is mechanical strength and wear resistance: Select a glass-filled PTFE material for components or a tough ETFE coating for surfaces.

- If your primary focus is creating a reliable, form-fitting seal or gasket: Expanded PTFE (ePTFE) is the material specifically engineered for this purpose.

- If your primary focus is bonding a Teflon component to another material: You must use a specially prepared material like Etched PTFE to ensure proper adhesion.

By understanding these key distinctions, you can select the precise fluoropolymer engineered to solve your specific challenge.

Summary Table:

| Type | Form | Key Properties | Common Applications |

|---|---|---|---|

| Pure PTFE | Solid Material | Excellent chemical inertness, low friction, high temp (260°C+) | Seals, bushings, labware |

| Glass-Filled PTFE | Solid Material | High compressive strength, improved wear resistance | Structural components, bearings |

| Expanded PTFE (ePTFE) | Solid Material | Porous, flexible, excellent sealing properties | Gaskets, seals |

| PTFE Coating | Coating | Highest heat resistance (up to 290°C), non-stick | Cookware, industrial surfaces |

| PFA Coating | Coating | High heat resistance, durable, non-porous | Chemical processing, demanding industrial uses |

| FEP Coating | Coating | Good chemical resistance, smooth surface, lower heat (200°C) | Non-stick surfaces, electrical insulation |

| ETFE Coating | Coating | Extreme toughness, abrasion resistance | Machinery parts, wire coatings |

Need a Custom Teflon (PTFE) Solution?

KINTEK specializes in manufacturing high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a standard part or a custom-fabricated solution from prototype to high-volume production, our expertise in precision manufacturing ensures you get the right material for your specific requirements—balancing temperature resistance, mechanical strength, and chemical compatibility.

Let us help you select the perfect fluoropolymer for your project. Contact our experts today to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries