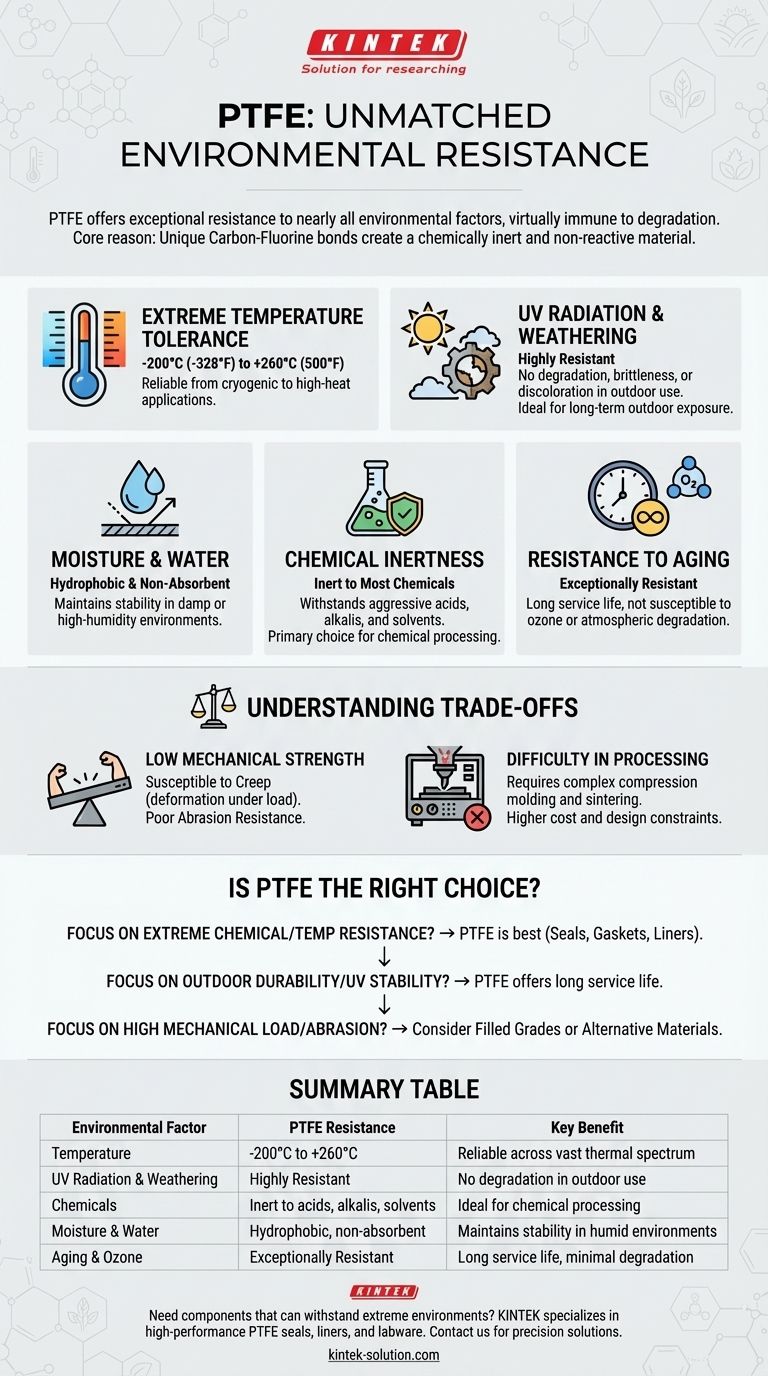

In essence, Polytetrafluoroethylene (PTFE) offers exceptional resistance to nearly all environmental factors it might encounter. It is virtually immune to degradation from UV radiation, weathering, moisture, and ozone. Furthermore, it maintains its integrity across an extremely wide temperature range and is inert to most chemicals.

The core reason for PTFE's remarkable environmental durability lies in its unique molecular structure. The incredibly strong carbon-fluorine bonds create a chemically inert and non-reactive material that is highly stable across a vast range of conditions.

A Breakdown of Key Environmental Resistances

PTFE's resilience is not just a single property but a combination of several distinct resistances that make it suitable for the most demanding applications, from outdoor infrastructure to harsh industrial settings.

Extreme Temperature Tolerance

PTFE performs reliably across a vast thermal spectrum, far exceeding the limits of most other plastics and elastomers.

It maintains its properties in continuous service at temperatures from -200°C (-328°F) up to +260°C (500°F). This makes it suitable for both cryogenic and high-heat applications.

UV Radiation and Weathering

Components made from PTFE are ideal for outdoor use because they do not suffer degradation from long-term exposure to sunlight.

The material is highly resistant to UV radiation, meaning it won't become brittle, discolor, or lose its mechanical properties when used in outdoor machinery, construction, or architectural elements.

Moisture and Water

PTFE is hydrophobic, meaning it repels water and resists moisture absorption.

This property ensures that components like seals and gaskets maintain their dimensional stability and performance even in damp or high-humidity environments.

Chemical Inertness

One of PTFE's most defining characteristics is its resistance to chemical attack.

It can withstand exposure to a wide range of aggressive substances, including strong acids, alkalis, and solvents, without degrading. This makes it a primary choice for seals, linings, and components in chemical processing.

Resistance to Aging

Unlike many other materials, PTFE is not susceptible to degradation over time from atmospheric factors.

It does not break down from exposure to ozone or the effects of aging, ensuring an exceptionally long and reliable service life for critical components.

Understanding the Trade-offs

While its environmental resistance is world-class, PTFE is not the ideal solution for every engineering problem. Its unique properties come with mechanical limitations that must be considered.

Low Mechanical Strength

PTFE is a relatively soft material. It is susceptible to creep (deformation under a sustained load) and has poor abrasion resistance compared to other engineering plastics.

Difficulty in Processing

PTFE cannot be processed using conventional melt techniques like injection molding. It must be processed through more complex methods like compression molding and sintering, which can impact design complexity and cost.

Is PTFE the Right Choice for Your Application?

Choosing the correct material requires balancing environmental needs with mechanical demands.

- If your primary focus is extreme chemical and temperature resistance: PTFE is almost certainly the best choice, especially for static applications like seals, gaskets, and liners.

- If your primary focus is outdoor durability and UV stability: PTFE offers an exceptionally long service life with virtually no degradation from weather, making it ideal for long-term installations.

- If your primary focus is high mechanical load or abrasion resistance: You should consider using filled grades of PTFE (e.g., glass or carbon-filled) or alternative materials designed for mechanical strength.

Ultimately, PTFE's unparalleled environmental stability makes it a foundational material for creating components that must survive in the most challenging conditions.

Summary Table:

| Environmental Factor | PTFE Resistance | Key Benefit |

|---|---|---|

| Temperature | -200°C to +260°C | Reliable from cryogenic to high-heat applications |

| UV Radiation & Weathering | Highly Resistant | No degradation or brittleness in outdoor use |

| Chemicals | Inert to acids, alkalis, solvents | Ideal for chemical processing components |

| Moisture & Water | Hydrophobic, non-absorbent | Maintains stability in humid environments |

| Aging & Ozone | Exceptionally Resistant | Long service life with minimal degradation |

Need components that can withstand extreme environments?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services ensure your parts deliver unmatched durability, chemical resistance, and long-term reliability, whether for prototypes or high-volume orders.

Let’s engineer a solution for your toughest conditions. Contact us today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- What are the disadvantages of bronze bushings? Understanding the Trade-Offs for Heavy-Duty Applications

- What are the dielectric properties of PTFE products? Ensure Stable, High-Performance Electrical Insulation

- Why is PTFE considered biocompatible and inert? The Science Behind Its Chemical Stability

- What are some common applications of PTFE based on its electrical properties? | High-Frequency & High-Voltage Solutions

- How is PTFE utilized in the medical and pharmaceutical industries? Ensure Purity and Biocompatibility

- What are the key characteristics of polytetrafluoroethylene (PTFE)? Unlocking High-Performance Material Properties

- What makes PTFE difficult to adhere to or weld? Unlocking the Secrets of Teflon® Bonding

- What are the safety considerations when using PTFE at high temperatures? Managing Decomposition Risks