Polytetrafluoroethylene (PTFE) was discovered accidentally on April 6, 1938, by chemist Dr. Roy J. Plunkett while working for DuPont. He was attempting to create a new, non-toxic refrigerant, but one of his test cylinders of tetrafluoroethylene gas appeared empty despite its weight indicating it was still full. Upon investigating, he discovered the gas had transformed into a strange, waxy white solid with incredibly slippery and inert properties.

The discovery of PTFE is a classic story of scientific serendipity. What began as a failed chemical experiment in 1938 quickly evolved into the development of a strategic, high-performance material that found its first critical use in the Manhattan Project before becoming a household name.

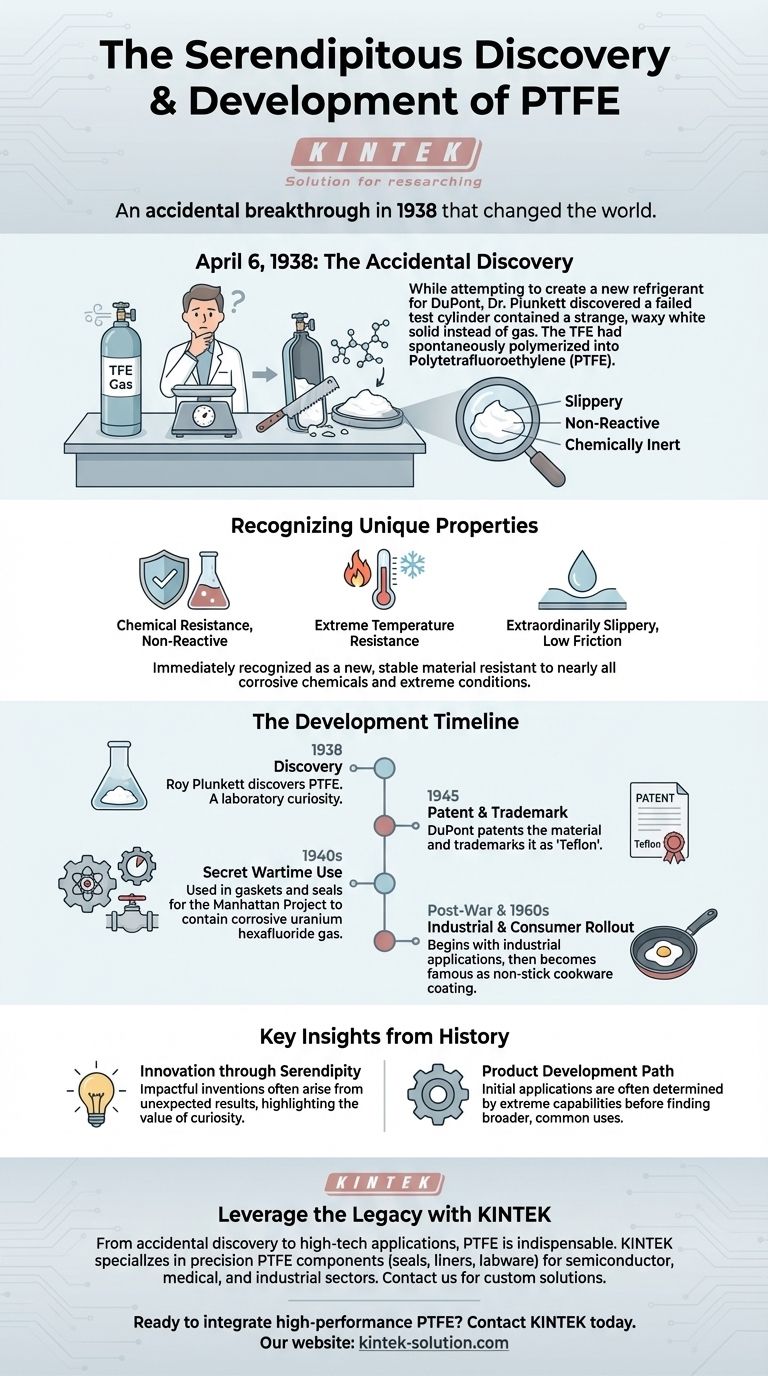

The Accidental Discovery

The creation of PTFE was not the result of a targeted research goal. It was an unexpected outcome of an entirely different project, highlighting how observation and curiosity can lead to breakthrough innovations.

The Refrigerant Experiment

Dr. Plunkett's primary objective was to synthesize a new chlorofluorocarbon (CFC) to be used as a refrigerant. His process involved using tetrafluoroethylene (TFE) gas, which he stored in small, pressurized cylinders.

A Failed Process Reveals a Mystery

During one experiment, the TFE gas stopped flowing from a cylinder before the cylinder's weight indicated it was empty. Rather than discarding the apparently faulty cylinder, Plunkett and his assistant sawed it open to investigate the cause of the blockage.

A Peculiar White Solid

Inside, they did not find gas but a white, waxy solid. The TFE gas had spontaneously polymerized, forming long chains of molecules to create a new substance. This new polymer was polytetrafluoroethylene, or PTFE.

From Lab Curiosity to Strategic Material

Plunkett immediately recognized that the new material was not ordinary. Its unique combination of properties prompted further investigation and a careful, strategic development process by DuPont.

Recognizing Unique Properties

The new polymer was found to be extraordinarily slippery and non-reactive. It was resistant to nearly every corrosive chemical and could withstand extreme temperatures, making it one of the most stable materials ever created.

The Path to Patent and Trademark

Recognizing its potential, DuPont patented the invention in 1945. The material was later given the commercial trademark Teflon, which would eventually become a globally recognized brand.

Secret Wartime Development

Before it ever reached a consumer kitchen, PTFE played a critical role in World War II. Its extreme chemical resistance made it the only material suitable for use in gaskets and seals that could contain the highly corrosive uranium hexafluoride gas used during the Manhattan Project to produce the first atomic bomb.

The Development Timeline Explained

The journey from discovery to widespread use spanned several decades, with its initial applications dictated by global events and its highly specialized nature.

The 1930s: Discovery

The story begins and ends in this decade with the accidental discovery in 1938. For the remainder of the 1930s, PTFE remained a laboratory curiosity while its properties were studied.

The 1940s: Strategic Military Application

This decade was defined by development for military purposes. After its patent in 1945, its primary application was kept secret and used exclusively for the war effort, particularly in nuclear material processing.

Post-War: Industrial and Consumer Rollout

After the war, DuPont began seeking commercial applications for PTFE. It was initially used in specialized industrial settings, but by the 1960s, it famously found its way into households as the non-stick coating for cookware.

Key Insights from PTFE's History

Understanding the origin of PTFE provides a valuable perspective on the nature of scientific progress and material development.

- If your primary focus is on innovation: The discovery of PTFE shows that some of the most impactful inventions are not planned but are born from curiosity in the face of unexpected results.

- If your primary focus is on product development: PTFE's history demonstrates that a material's initial application is often determined by its most extreme capabilities, only later finding broader, more common uses.

This accidental discovery in a New Jersey lab ultimately produced a material that has been indispensable in everything from aerospace engineering to modern medicine.

Summary Table:

| Year | Key Event |

|---|---|

| 1938 | PTFE is accidentally discovered by Dr. Roy J. Plunkett at DuPont. |

| 1945 | PTFE is patented by DuPont and given the Teflon trademark. |

| 1940s | Used as a strategic material for seals and gaskets in the Manhattan Project. |

| 1960s | Gains widespread consumer fame as a non-stick coating for cookware. |

Leverage the Legacy of PTFE with KINTEK

From its accidental discovery to its critical role in high-tech industries, PTFE's unique properties—chemical inertness, high-temperature resistance, and low friction—make it indispensable. At KINTEK, we specialize in manufacturing precision PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Whether you need custom prototypes or high-volume production, our expertise ensures superior performance and reliability.

Ready to integrate high-performance PTFE solutions into your projects? Contact KINTEK today to discuss your specific requirements and discover how our custom fabrication can drive your innovation forward.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the environmental concerns associated with PTFE manufacturing? Assessing the Full Lifecycle Impact

- What are the characteristics of PFA Teflon? | Extreme Performance Meets Design Freedom

- How was PTFE discovered and by whom? A Serendipitous Breakthrough in Material Science

- What industry specifications does PTFE conform to? Ensuring Compliance for Food, Medical, and Aerospace

- What makes PTFE chemically resistant and why is this advantageous? Achieve Unmatched Reliability in Harsh Environments

- What is modified PTFE and how does it differ from standard PTFE? A Guide to Enhanced Performance

- Is PTFE safe for use in electrical environments? Achieve Superior Insulation & Reliability

- What are the physical properties of PTFE? Unlocking Its High-Performance Capabilities