In 1938, a remarkable material was discovered entirely by accident. Dr. Roy Plunkett, a chemist at DuPont, was researching new coolant gases when he found that a cylinder of tetrafluoroethylene gas appeared empty, yet still weighed as much as a full one. Upon cutting it open, he discovered a waxy, white solid that was incredibly slippery and inert, which would later be patented and trademarked as Teflon.

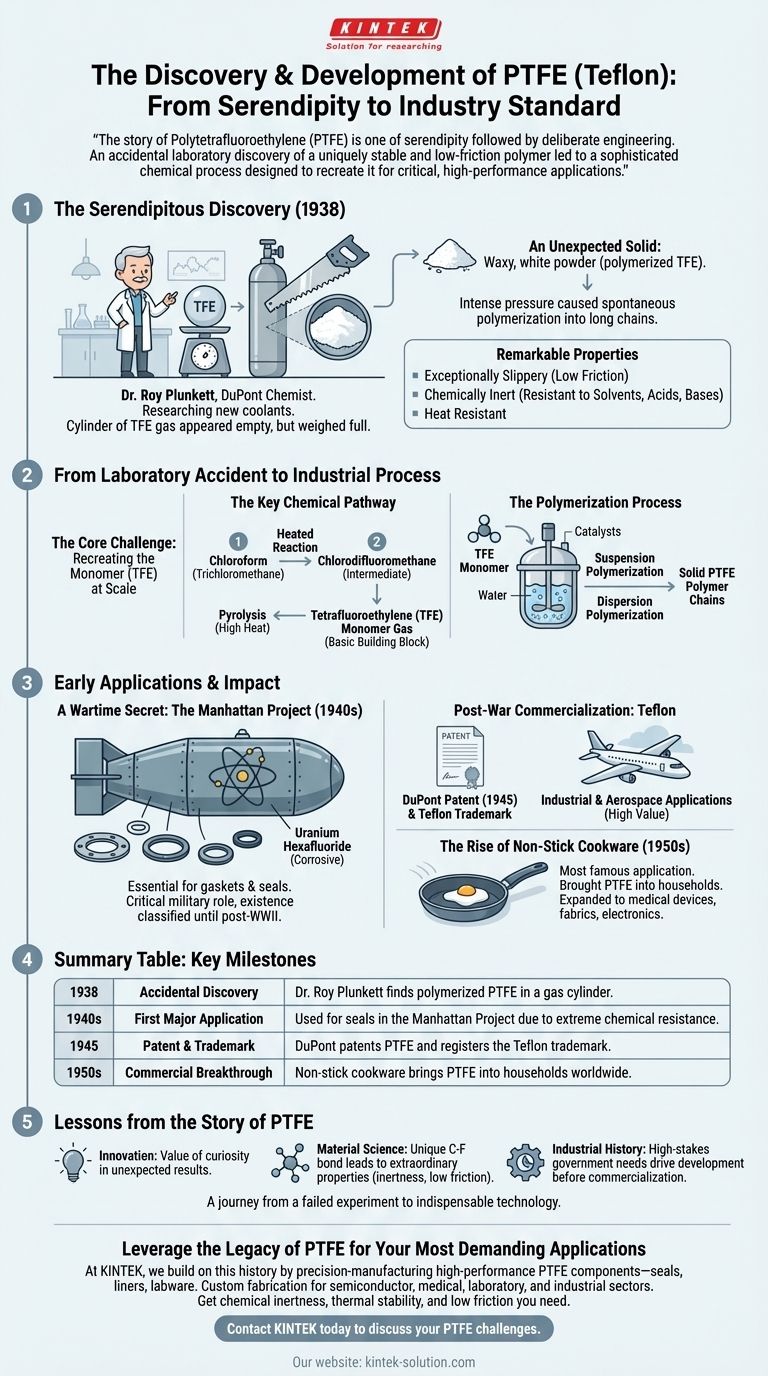

The story of Polytetrafluoroethylene (PTFE) is one of serendipity followed by deliberate engineering. An accidental laboratory discovery of a uniquely stable and low-friction polymer led to a sophisticated chemical process designed to recreate it for critical, high-performance applications.

The Serendipitous Discovery

An Unexpected Solid

Dr. Plunkett was not trying to invent a new polymer. His goal was to develop a new, non-toxic refrigerant, a type of chlorofluorocarbon (CFC).

The experiment involved a cylinder of tetrafluoroethylene (TFE) gas. When his assistant found no gas would come out despite the cylinder's weight, Plunkett investigated the anomaly personally.

Investigating the Anomaly

Instead of discarding the cylinder, his curiosity led him to saw it open. Inside, he found a waxy, white powder that had polymerized from the gas.

The intense pressure inside the cylinder had caused the individual TFE gas molecules to spontaneously link together into the long chains of a solid polymer: PTFE.

Recognizing "Remarkable Properties"

Plunkett and his team immediately began testing the strange new substance. They found it possessed a unique and valuable set of properties.

It was exceptionally slippery, with one of the lowest coefficients of friction of any known solid. It was also extremely resistant to heat and chemical corrosion, failing to react with nearly every solvent, acid, and base.

From Laboratory Accident to Industrial Process

The Core Challenge: Recreating the Monomer

Once the value of PTFE was understood, the challenge became producing it intentionally and at scale. This required a multi-step chemical manufacturing process.

The critical first step is to synthesize the "monomer" or the basic molecular building block—tetrafluoroethylene (TFE) gas—from common industrial chemicals.

The Key Chemical Pathway

The process typically begins with chloroform (trichloromethane). This is reacted to produce chlorodifluoromethane.

This intermediate chemical is then heated in a process called pyrolysis to finally produce the TFE monomer, the same gas Plunkett had in his cylinder.

The Polymerization Process

With a reliable supply of the TFE monomer, the final step is to recreate the conditions for polymerization, turning the gas into a solid.

This is accomplished through either suspension polymerization or dispersion polymerization, processes that use water and catalysts to link the TFE molecules into the long, stable polymer chains of PTFE.

Early Applications and Impact

A Wartime Secret: The Manhattan Project

PTFE's first major application was a closely guarded secret. Its extreme chemical resistance was essential for creating gaskets and seals that could handle the highly corrosive uranium hexafluoride used in the atomic bomb project.

Because of this critical military role, the material's existence was not widely publicized until after World War II.

Post-War Commercialization: Teflon

DuPont patented the substance in 1945 and registered the Teflon trademark. It began looking for commercial applications for its unique material.

The high production cost initially limited its use to high-value industrial and aerospace applications, where its performance justified the expense.

The Rise of Non-Stick Cookware

The most famous application—non-stick cookware—was developed in the 1950s. This brought PTFE into households around the world and made "Teflon" a common name.

From there, its use expanded into countless areas, including medical devices, protective fabrics, and electronics.

Lessons from the Story of PTFE

The history of PTFE provides a clear blueprint for how scientific discovery often unfolds.

- If your primary focus is on innovation: The key takeaway is the immense value of curiosity in the face of an unexpected result.

- If your primary focus is on material science: The key takeaway is how a unique molecular structure—the strong carbon-fluorine bond—can lead to extraordinary properties like chemical inertness and low friction.

- If your primary focus is on industrial history: The key takeaway is how a material's development is often driven by high-stakes government needs before it is refined for the commercial market.

This journey from a failed experiment to a world-changing material exemplifies the powerful path from scientific accident to indispensable technology.

Summary Table:

| Key Milestone | Year | Description |

|---|---|---|

| Accidental Discovery | 1938 | Dr. Roy Plunkett finds polymerized PTFE in a gas cylinder. |

| First Major Application | 1940s | Used for seals in the Manhattan Project due to extreme chemical resistance. |

| Patent & Trademark | 1945 | DuPont patents PTFE and registers the Teflon trademark. |

| Commercial Breakthrough | 1950s | Non-stick cookware brings PTFE into households worldwide. |

Leverage the Legacy of PTFE for Your Most Demanding Applications

At KINTEK, we build on this history of innovation by precision-manufacturing high-performance PTFE components—from seals and liners to custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom fabrication services ensure you get the chemical inertness, thermal stability, and low friction you need, from prototypes to high-volume orders.

Contact KINTEK today to discuss how our PTFE solutions can solve your unique challenges.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- What are the recommended PTFE formulations for the chemical processing industry and why? Optimize for Durability and Chemical Resistance

- What are the mechanical properties of FR4 PCB material? Understanding Rigidity, Thermal Limits & Cost

- Why is PTFE ideal for high-purity applications? Ensuring Absolute Chemical and Biological Inertness

- How does PTFE benefit aerospace applications? Achieve Superior Performance in Extreme Environments

- What are the common grades of PTFE and their properties? Choose the Right Grade for Your Application

- What is ePTFE and how is it produced? Unlock the Power of Microporous PTFE

- How does PTFE compare to Polyethylene (PE) in terms of chemical and temperature resistance? Choose the Right Polymer for Extreme Conditions

- How was PTFE discovered? The Accidental Invention of a Super-Material