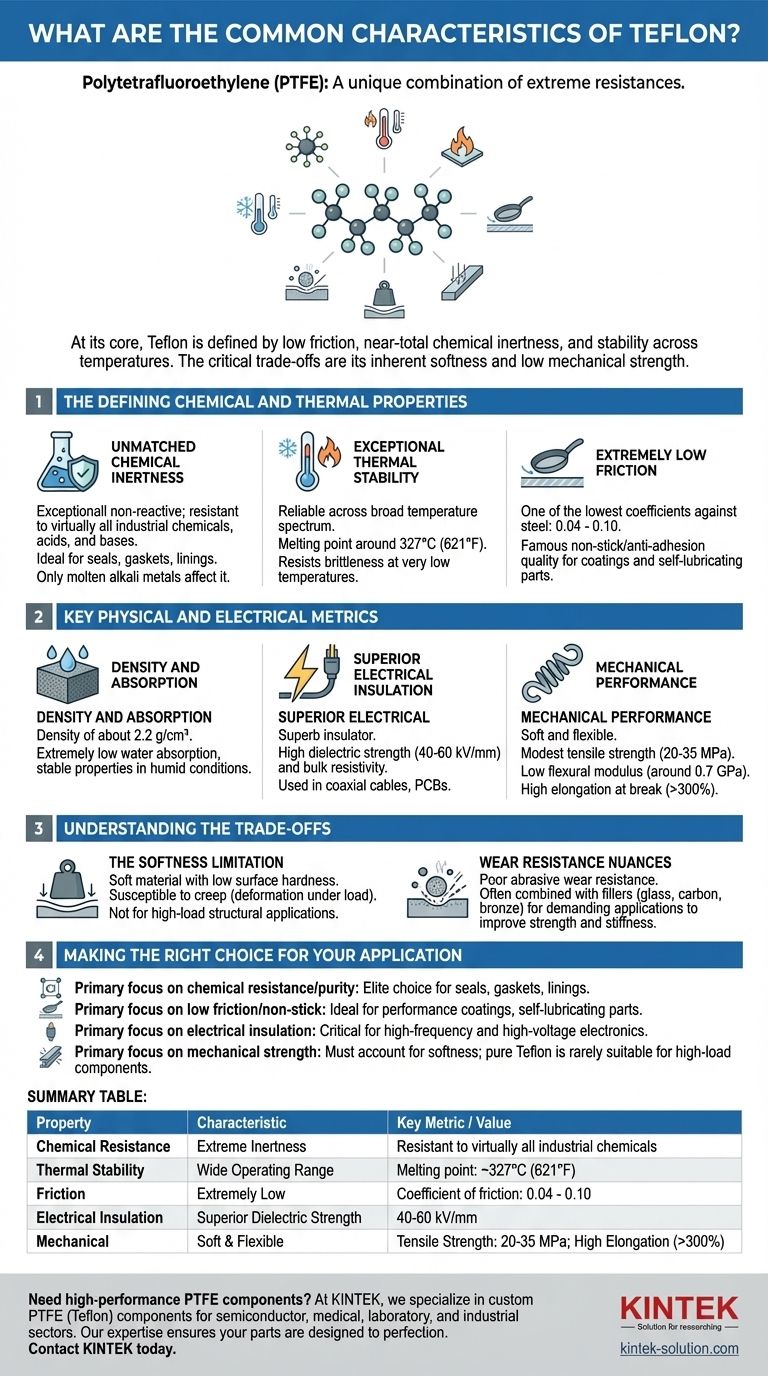

At its core, Teflon is a fluoropolymer defined by a unique combination of extreme resistances. Best known by its chemical name Polytetrafluoroethylene (PTFE), it is a soft, dense material characterized by an incredibly low coefficient of friction, near-total chemical inertness, and stability across a wide range of temperatures.

While Teflon's exceptional resistance to chemicals, heat, and electricity makes it a premier material for harsh environments, its inherent softness and low mechanical strength are the critical trade-offs that must be managed in any design.

The Defining Chemical and Thermal Properties

Teflon's unique molecular structure, a strong chain of carbon atoms completely shielded by fluorine atoms, is the source of its most famous characteristics.

Unmatched Chemical Inertness

Teflon is exceptionally non-reactive and resistant to virtually all industrial chemicals, acids, and bases. This makes it an ideal material for seals, gaskets, and linings in corrosive environments.

Only a few highly reactive substances, such as molten alkali metals, are known to affect it.

Exceptional Thermal Stability

The material performs reliably across an extremely broad temperature spectrum. It remains stable at high temperatures, with a very high melting point around 327°C (600 K).

It also maintains its properties at very low temperatures, resisting brittleness where other polymers would fail.

Extremely Low Friction

Teflon has one of the lowest coefficients of friction of any known solid, with values against steel as low as 0.04 - 0.10.

This property is responsible for its famous non-stick or anti-adhesion quality, which is fundamental to its use in cookware, coatings, and self-lubricating bearings.

Key Physical and Electrical Metrics

Beyond its core resistances, Teflon's physical properties define its use in specific engineering applications.

Density and Absorption

Teflon is a relatively dense polymer, with a typical density of about 2.2 g/cm³.

It also exhibits extremely low water absorption, ensuring its properties remain stable and predictable even in humid or submerged conditions.

Superior Electrical Insulation

The strong carbon-fluorine bonds prevent the free flow of electrons, making Teflon a superb electrical insulator.

It has a very high dielectric strength (40-60 kV/mm) and bulk resistivity, making it a top choice for high-frequency applications like coaxial cable insulation and printed circuit boards.

Mechanical Performance

Mechanically, Teflon is a soft and flexible material. It has a modest tensile strength (20-35 MPa) and a low flexural modulus (around 0.7 GPa), meaning it is not rigid.

However, it is tough, with a very high elongation at break (over 300%), allowing it to deform significantly without fracturing.

Understanding the Trade-offs

Teflon's greatest strengths are directly linked to its primary limitations. An effective design must account for these trade-offs.

The Softness Limitation

The same chemical stability that makes Teflon non-stick and non-reactive also results in a soft material with low surface hardness.

It is susceptible to creep (deformation under sustained load) and is not suitable for high-load structural applications where rigidity and compressive strength are required.

Wear Resistance Nuances

While its low friction reduces adhesive wear, pure Teflon's softness can lead to poor abrasive wear resistance.

For demanding mechanical applications like bearings or seals, Teflon is often combined with fillers (like glass, carbon, or bronze) to significantly improve its strength, stiffness, and wear resistance.

Making the Right Choice for Your Application

Selecting Teflon depends entirely on whether your application prioritizes its unique resistances over the need for mechanical strength.

- If your primary focus is chemical resistance or purity: Teflon is an elite choice for seals, gaskets, and linings in aggressive chemical environments.

- If your primary focus is low friction or non-stick surfaces: Its uniquely low coefficient of friction makes it ideal for performance coatings and self-lubricating mechanical parts.

- If your primary focus is electrical insulation: Its high dielectric strength is critical for insulating high-frequency and high-voltage electronics.

- If your primary focus is mechanical strength: You must account for its softness and low rigidity; pure Teflon is rarely suitable for high-load structural components.

Understanding this balance between extreme resilience and mechanical softness is the key to successfully applying Teflon to your most demanding engineering challenges.

Summary Table:

| Property | Characteristic | Key Metric / Value |

|---|---|---|

| Chemical Resistance | Extreme Inertness | Resistant to virtually all industrial chemicals |

| Thermal Stability | Wide Operating Range | Melting point: ~327°C (621°F) |

| Friction | Extremely Low | Coefficient of friction: 0.04 - 0.10 |

| Electrical Insulation | Superior Dielectric Strength | 40-60 kV/mm |

| Mechanical | Soft & Flexible | Tensile Strength: 20-35 MPa; High Elongation (>300%) |

Need high-performance PTFE components that leverage these unique characteristics?

At KINTEK, we specialize in the precision manufacturing of custom PTFE (Teflon) components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between Teflon's unparalleled resistances and its mechanical limitations. Our expertise ensures your parts are designed and fabricated to perfection, from prototypes to high-volume orders, delivering the reliability your harsh environments demand.

Contact KINTEK today to discuss your specific application and receive a quote for custom PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does PTFE contribute to sustainable and eco-friendly design practices? Enhance Durability and Efficiency

- What are the key characteristics of PTFE? A Guide to Its Extreme Performance

- What are the key properties of Teflon (PTFE) that make it suitable for industrial applications?

- What are the characteristics of PFA material? A Guide to Its High-Performance Balance

- What are the limitations of PTFE materials? Understand the Key Trade-Offs Before You Spec

- Why is understanding Teflon's friction mechanism important? Master Its Self-Lubricating Wear for Better Applications

- What are some common household uses of Teflon? Discover the Material Science in Your Home

- What are some common uses of PTFE? Unlock Extreme Performance for Your Industry