In its most practical sense, Polytetrafluoroethylene (PTFE) is a problem-solving surface treatment. A PTFE coating provides a unique combination of four key advantages: exceptional non-stick properties, extreme chemical resistance, stability across a wide temperature range, and high-performance electrical insulation.

While many materials excel in one area, PTFE's true advantage lies in its rare combination of elite properties. It simultaneously provides an ultra-low-friction surface that is also chemically inert and stable in extreme temperatures, making it a uniquely versatile solution for hostile and demanding environments.

The Defining Characteristic: Extreme Chemical Inertness

A primary advantage of PTFE is its ability to resist degradation from nearly all common chemicals. This makes it a critical material for protecting components in corrosive environments.

The Strength of the Carbon-Fluorine Bond

At a molecular level, PTFE consists of a chain of carbon atoms completely shielded by fluorine atoms. The carbon-fluorine (C-F) bond is one of the strongest single bonds in organic chemistry.

This powerful bond structure makes the material non-reactive and inert to most acids, bases, and solvents.

Implications for Industrial Use

This chemical resistance is not just a lab curiosity; it is essential for industrial applications.

Equipment, vessels, and pipes coated with PTFE can safely handle highly corrosive materials without degrading the underlying substrate, significantly extending the life of critical components.

Unmatched Surface Properties: Non-Stick and Low Friction

PTFE is perhaps most famous for its non-stick and low-friction characteristics, often marketed under the brand name Teflon®.

An Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid, typically measured between 0.04 and 0.15.

This means that very few materials stick to its surface, and objects slide across it with minimal resistance. This property is often referred to as non-adhesiveness or having outstanding release capabilities.

From Cookware to Industrial Molds

The most recognized application is in non-stick cookware, but this property is vital in industry.

It is used on molds for manufacturing plastics and composites, allowing for easy release of the finished part. It also prevents buildup on machinery that processes sticky substances.

Performance in Extreme Temperatures

PTFE coatings maintain their integrity and performance across an exceptionally wide operational temperature range.

A Vast Operational Window

PTFE can withstand continuous service temperatures up to 260°C (500°F) without significant degradation.

On the other end of the spectrum, it remains stable and functional at cryogenic temperatures as low as -270°C (-454°F), where many other materials would become brittle and fail.

Superior Electrical Insulation

For electrical and electronic applications, PTFE is a first-class insulator.

High Dielectric Strength

Dielectric strength is a measure of a material's ability to withstand a high voltage without an electrical breakdown. PTFE exhibits excellent dielectric strength, exceeding 30 kV/mm.

It effectively blocks the flow of electricity, making it ideal for insulating wires, cables, and sensitive electronic components. Its low dielectric constant also makes it valuable in high-frequency applications.

Understanding the Trade-offs

No material is perfect. Acknowledging PTFE's limitations is key to using it effectively.

Softness and Abrasion Resistance

While durable in many ways, PTFE is a relatively soft material. In its pure form, it is not ideal for applications involving high mechanical wear or abrasion.

For high-wear scenarios, reinforced PTFE coatings that include other materials (like graphite or glass fiber) are often used to improve hardness and durability.

Not a Structural Material

PTFE is a surface coating, not a load-bearing structural material. Its benefits are realized when applied as a thin layer—typically 0.0003 to 0.0008 inches—onto a stronger substrate.

Application Sensitivity

The performance of a PTFE coating is highly dependent on proper surface preparation and application. An improperly applied coating can fail to adhere or deliver the expected benefits.

Making the Right Choice for Your Goal

To decide if PTFE is the right solution, match its strengths to your primary objective.

- If your primary focus is corrosion protection: PTFE's chemical inertness makes it one of the most reliable choices for protecting parts from acids, bases, and solvents.

- If your primary focus is reducing friction or creating a release surface: PTFE's ultra-low coefficient of friction is nearly unmatched, making it a default choice for non-stick and low-drag applications.

- If your primary focus is performance in extreme temperatures: PTFE's stability from cryogenic lows to high heat provides a consistent and reliable surface where other polymers would fail.

- If your primary focus is abrasion or wear resistance: Pure PTFE may not be the best fit; you should explore reinforced PTFE composites or harder coating materials.

Understanding these core properties and their inherent trade-offs is the key to leveraging PTFE's unique capabilities for your specific project.

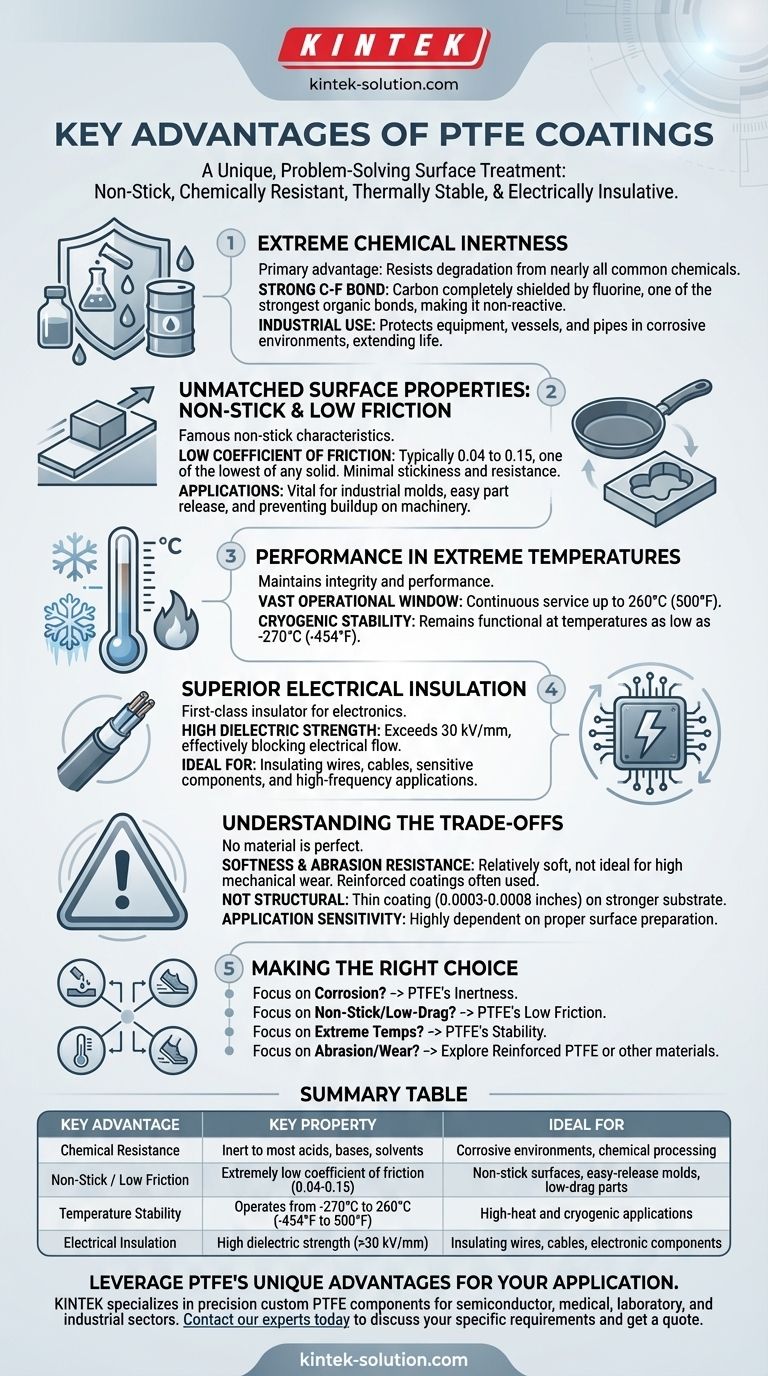

Summary Table:

| Key Advantage | Key Property | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to most acids, bases, solvents | Corrosive environments, chemical processing |

| Non-Stick / Low Friction | Extremely low coefficient of friction (0.04-0.15) | Non-stick surfaces, easy-release molds, low-drag parts |

| Temperature Stability | Operates from -270°C to 260°C (-454°F to 500°F) | High-heat and cryogenic applications |

| Electrical Insulation | High dielectric strength (>30 kV/mm) | Insulating wires, cables, electronic components |

Leverage PTFE's unique advantages for your application. KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures your components deliver superior non-stick performance, chemical resistance, and thermal stability. Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industrial applications commonly use PTFE packing? Essential Sealing Solutions for Demanding Industries

- What are the properties of glass-filled PTFE? Enhanced Strength & Wear Resistance for Demanding Applications

- What industries commonly use PTFE gasket materials? Ensure Sealing Integrity in Demanding Environments

- What are the signs that PTFE expansion bellows need replacement? Avoid Costly System Failures

- Why is compression molding preferred for certain PTFE applications? For Superior Seals and Machinable Stock Shapes

- How should Teflon O-rings be maintained? A Proactive Guide to Prevent Seal Failure

- What are the main properties of PTFE gaskets? Unlock Superior Sealing in Extreme Conditions

- What types of environments are PTFE rotary shaft seals suitable for? Engineered for Extreme Chemical, Temperature, and Speed