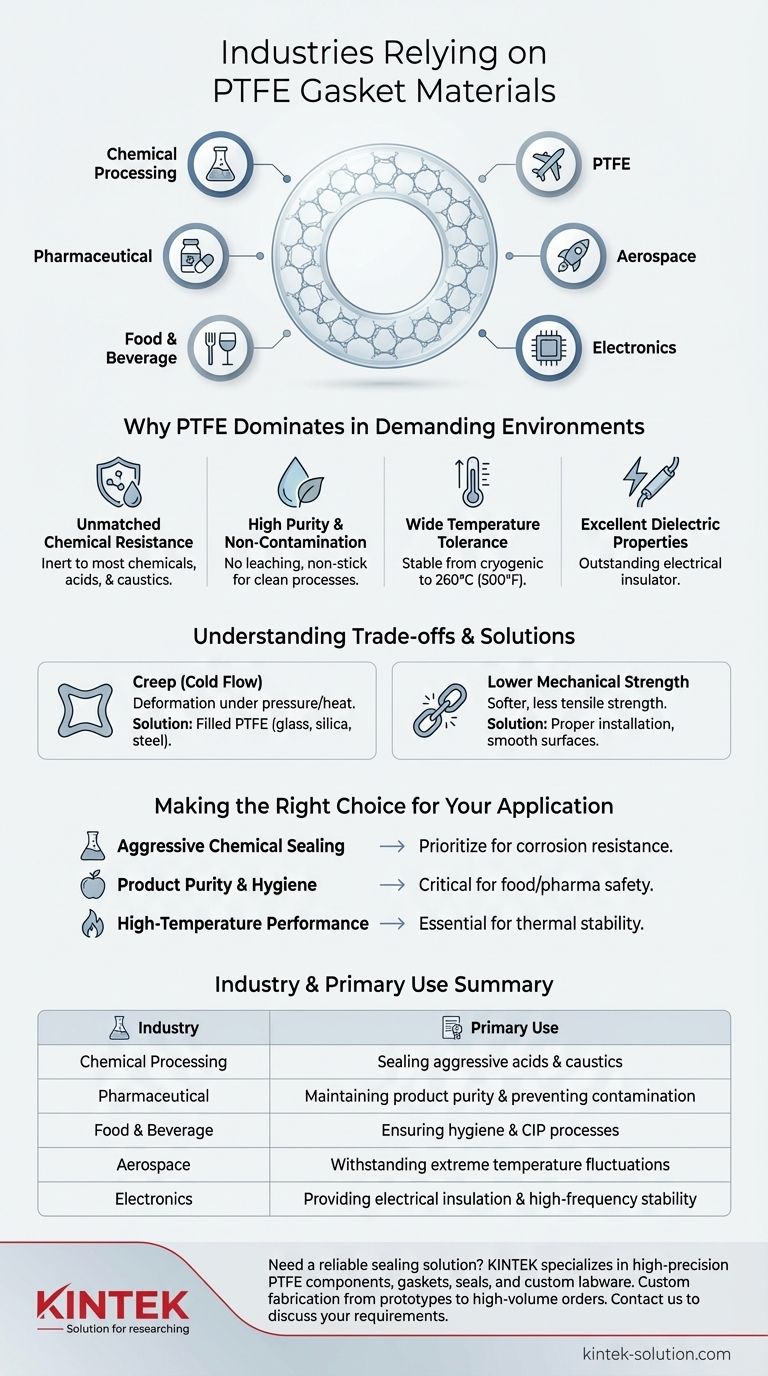

To put it directly, PTFE gasket materials are essential in any industry where purity and chemical resistance are paramount. The most common sectors include Chemical Processing, Pharmaceutical, Food & Beverage, Aerospace, and Electronics, each leveraging specific properties of this versatile polymer for critical sealing applications.

The widespread use of PTFE is not about a single feature, but its unique combination of extreme chemical inertness, high-temperature stability, and inherent purity. This makes it the default choice for environments where contamination or corrosion is simply not an option.

Why PTFE Dominates in Demanding Environments

The value of PTFE gaskets is directly tied to a core set of properties that make them uniquely suited for challenging operational conditions. Understanding these characteristics explains why certain industries rely on them so heavily.

Unmatched Chemical Resistance

PTFE is famously inert and resistant to nearly all industrial chemicals, acids, and caustics. This makes it indispensable for applications involving aggressive media.

This property is why the Chemical, Petrochemical, and Pulp & Paper industries specify PTFE for gaskets, valves, and pump components that are in constant contact with corrosive substances.

High Purity and Non-Contamination

Standard PTFE is inherently pure and does not leach contaminants into the media it contacts. Its surface is also extremely non-stick, which prevents material buildup and facilitates clean-in-place (CIP) processes.

This is the critical reason for its dominance in the Food & Beverage and Pharmaceutical industries, where preventing product contamination is a regulatory and safety necessity.

Wide Temperature Tolerance

PTFE gaskets maintain their integrity and sealing capability across an exceptionally broad temperature range, from cryogenic lows to highs of around 260°C (500°F).

This thermal stability is crucial in Aerospace and Automotive applications, where components must perform reliably under extreme temperature fluctuations.

Excellent Dielectric Properties

PTFE is an outstanding electrical insulator, meaning it does not conduct electricity. It maintains this property even at high frequencies and temperatures.

This makes it a go-to material in the Electronics industry for insulating high-performance wires, cables, and sensitive components from electrical interference and short-circuiting.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires acknowledging its specific limitations.

Susceptibility to Creep (Cold Flow)

One of the most well-known characteristics of pure PTFE is its tendency to "creep" or deform over time under sustained pressure, especially at elevated temperatures.

This can lead to a loss of bolt torque and potential leaks. To counteract this, many PTFE gaskets are filled with materials like glass, silica, or stainless steel to enhance rigidity and creep resistance.

Lower Mechanical Strength

Compared to metallic gaskets or some other engineered polymers, PTFE has lower tensile strength and is softer. It is more susceptible to damage from over-tightening or surface imperfections on the sealing faces (flanges).

Proper installation technique and ensuring smooth flange surfaces are critical for achieving a reliable seal with PTFE.

Making the Right Choice for Your Application

Your specific goal will determine if PTFE is the optimal gasket material for your needs.

- If your primary focus is aggressive chemical sealing: PTFE's inertness makes it the ideal material for containing corrosive fluids and preventing gasket degradation.

- If your primary focus is product purity and hygiene: The non-stick, non-contaminating nature of PTFE is critical for applications in food, beverage, and pharmaceutical processing.

- If your primary focus is high-temperature performance: PTFE maintains its sealing integrity across a wide thermal range where many common elastomers would fail.

Ultimately, selecting PTFE is a decision to prioritize reliability, safety, and purity in your most critical sealing applications.

Summary Table:

| Industry | Primary Use of PTFE Gaskets |

|---|---|

| Chemical Processing | Sealing aggressive acids and caustics |

| Pharmaceutical | Maintaining product purity and preventing contamination |

| Food & Beverage | Ensuring hygiene and clean-in-place (CIP) processes |

| Aerospace | Withstanding extreme temperature fluctuations |

| Electronics | Providing electrical insulation and high-frequency stability |

Need a reliable sealing solution for your critical application? KINTEK specializes in manufacturing high-precision PTFE components, including gaskets, seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide custom fabrication from prototypes to high-volume orders. Our focus on precision ensures your equipment operates safely and efficiently. Contact us today to discuss your specific requirements and let our expertise enhance your sealing performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining