When considering a gasket for demanding service, the properties of PTFE (Polytetrafluoroethylene) place it in a class of its own. PTFE gaskets are renowned for their exceptional chemical inertness, a very wide operational temperature range, an extremely low-friction surface, and excellent electrical insulation. These characteristics make them a default choice for sealing applications in corrosive environments and across extreme temperatures.

PTFE’s value comes from its unique molecular stability, which provides near-universal chemical resistance and thermal endurance. However, this same material softness introduces a critical mechanical trade-off—creep—that you must manage for a successful seal.

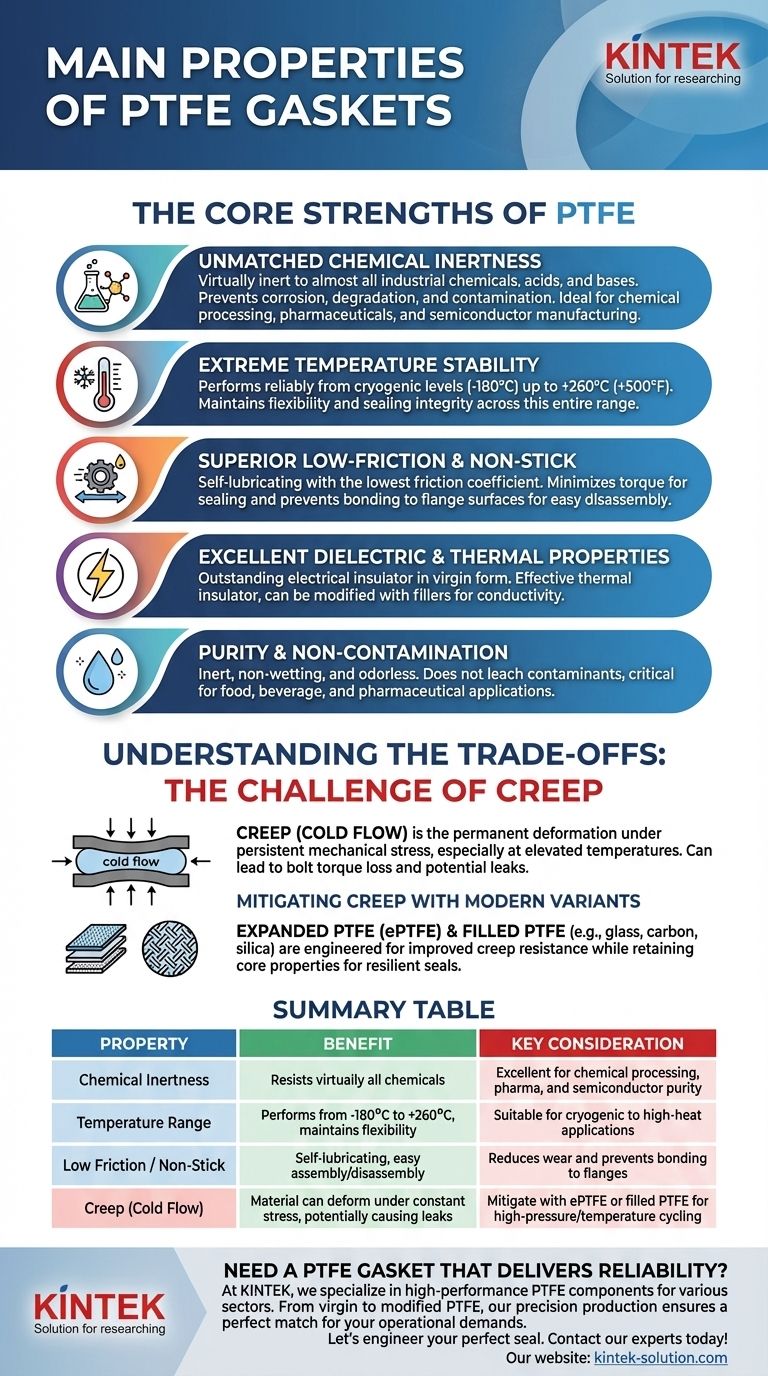

The Core Strengths of PTFE Gaskets

The unique properties of PTFE stem directly from its molecular structure, which consists of a carbon chain fully shielded by fluorine atoms. This strong carbon-fluorine bond is the source of its remarkable stability.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and bases. This non-reactive nature prevents the gasket from corroding, degrading, or contaminating the process media.

This makes it an essential sealing material in chemical processing, pharmaceuticals, and semiconductor manufacturing where purity and material compatibility are paramount.

Extreme Temperature Stability

PTFE gaskets perform reliably across an exceptionally broad temperature spectrum, typically from cryogenic levels around -180°C (-292°F) up to +260°C (500°F).

Unlike many elastomers that become brittle at low temperatures or degrade at high temperatures, PTFE maintains its flexibility and sealing integrity across this entire range.

Superior Low-Friction and Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material, giving it a self-lubricating quality. This minimizes the torque required to achieve a seal and reduces wear during assembly.

Its non-adhesive, or non-stick, surface also prevents the gasket from bonding to flange surfaces, simplifying disassembly and cleaning without damaging the sealing faces.

Excellent Dielectric and Thermal Properties

In its virgin (unfilled) form, PTFE is an outstanding electrical insulator, making it suitable for applications where electrical isolation is required.

It also serves as an effective thermal insulator, although this property can be modified with fillers to improve thermal conductivity if needed.

Purity and Non-Contamination

Because PTFE is inert, non-wetting, and odorless, it does not leach contaminants into the system. This property is critical for applications in the food, beverage, and pharmaceutical industries where process purity is a strict regulatory requirement.

Understanding the Trade-offs: The Challenge of Creep

While its core properties are exceptional, PTFE is not without limitations. Its primary mechanical weakness is a phenomenon known as creep, or "cold flow."

What is Creep (Cold Flow)?

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress, especially at elevated temperatures.

Because PTFE is a relatively soft material, it can slowly "flow" away from the point of highest pressure under the compressive load of a bolted flange.

The Impact on Sealing Performance

This gradual deformation can lead to a loss of bolt torque and a reduction in the stress on the gasket. Over time, this can compromise the integrity of the seal, leading to leaks.

This issue is most pronounced in applications with significant pressure cycling or wide temperature fluctuations, which can accelerate the rate of creep.

Mitigating Creep with Modern Variants

To address this challenge, manufacturers have developed modified forms of PTFE.

Expanded PTFE (ePTFE) and filled PTFE (which includes materials like glass, carbon, or silica) are engineered to significantly improve creep resistance while retaining most of PTFE's desirable chemical and thermal properties. These advanced materials provide a more resilient and reliable seal in demanding services.

Making the Right Choice for Your Application

Selecting the correct gasket material requires matching its properties to the demands of your system. Use these guidelines to make an informed decision.

- If your primary focus is chemical purity and broad resistance: Virgin PTFE is an ideal choice for applications in food, pharma, or aggressive chemical processing where contamination cannot be tolerated.

- If your primary focus is maintaining a reliable seal under high pressure or fluctuating temperatures: You must consider modified or expanded PTFE (ePTFE) to gain the necessary creep resistance for a durable, long-term seal.

- If your primary focus is a simple, low-cost seal for non-critical media: Standard elastomers may be more cost-effective if you do not require PTFE's extreme chemical or thermal capabilities.

Understanding these properties and their inherent trade-offs empowers you to select the right PTFE variant for a reliable and long-lasting seal.

Summary Table:

| Property | Benefit | Key Consideration |

|---|---|---|

| Chemical Inertness | Resists virtually all chemicals, ideal for corrosive environments. | Excellent for chemical processing, pharma, and semiconductor purity. |

| Temperature Range | Performs from -180°C to +260°C, maintaining flexibility. | Suitable for cryogenic to high-heat applications. |

| Low Friction / Non-Stick | Self-lubricating, easy assembly and disassembly. | Reduces wear and prevents bonding to flanges. |

| Creep (Cold Flow) | Material can deform under constant stress, potentially causing leaks. | Mitigate with ePTFE or filled PTFE for high-pressure/temperature cycling. |

Need a PTFE gasket that delivers reliability in your specific application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the ultimate chemical purity of virgin PTFE or the enhanced creep resistance of expanded or filled PTFE, our precision production and custom fabrication capabilities—from prototypes to high-volume orders—ensure you get a sealing solution perfectly matched to your operational demands.

Let's engineer your perfect seal. Contact our experts today to discuss your requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does carbon filler cause corrosion when combined with aluminum? Understanding Galvanic Corrosion Risks

- What is the biggest advantage of Teflon washers? Achieve Self-Lubricating, Low-Friction Performance

- What makes PTFE rotary shaft seals suitable for low friction or dry running applications? Unlock High-Speed, Dry-Running Performance

- In which industries are PTFE-coated O-rings commonly used? Enhance Sealing Performance in Demanding Applications

- What type of glass is used in glass-filled PTFE? The Definitive Answer for Superior Performance

- What are the general properties and applications of Teflon industrial coatings? Solve Complex Engineering Challenges

- What are the key properties of PTFE rods? A Guide to Extreme Performance Materials

- What are the mechanical properties of PTFE that make it durable? Leverage Specialized Resilience