PTFE's durability is not a result of brute strength, but from a unique combination of exceptional flexibility, chemical inertness, and an extremely low-friction surface. Its key mechanical properties include a very high elongation at break (200-400%), good impact strength, and excellent resistance to weathering. This allows it to function reliably in harsh environments where more rigid materials would fail.

The central takeaway is that PTFE's durability is highly specialized. It excels in applications requiring flexibility, chemical resistance, and low-friction sliding, but it is not designed for high-load structural applications due to its relative softness and susceptibility to deformation under pressure.

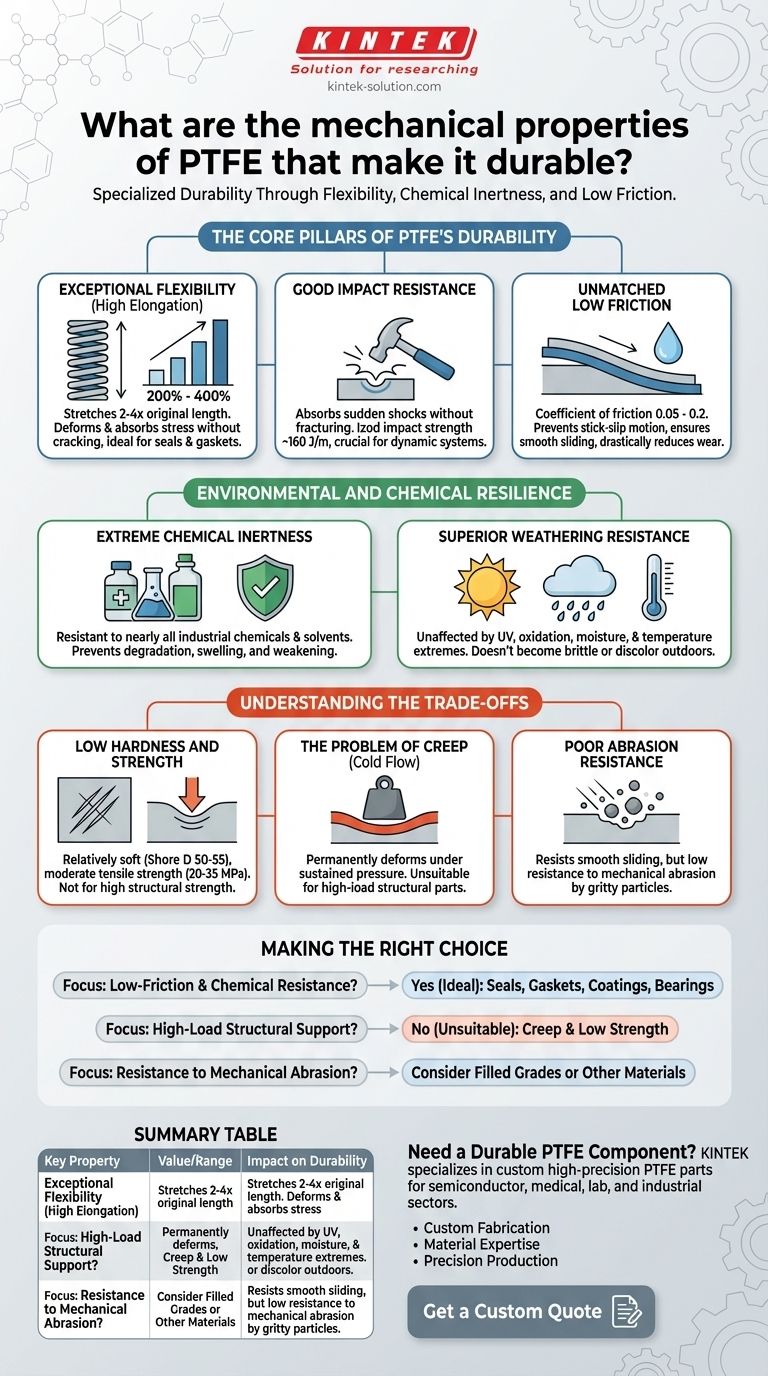

The Core Pillars of PTFE's Durability

The term "durability" for PTFE is best understood through three key mechanical characteristics that allow it to withstand stress and wear in specific ways.

Exceptional Flexibility (High Elongation)

PTFE has an elongation at break between 200% and 400%. This means it can stretch to over twice its original length before rupturing.

This extreme flexibility makes it incredibly tough. Instead of cracking or shattering under stress, it deforms and absorbs the energy, making it ideal for seals, gaskets, and liners that must conform to surfaces.

Good Impact Resistance

PTFE exhibits good Izod impact strength (around 160 J/m). It can absorb sudden shocks and impacts without fracturing.

This property is crucial for components in dynamic systems where parts may experience unexpected jolts or collisions. Its ability to absorb this energy without failing is a key component of its mechanical resilience.

Unmatched Low Friction

With a coefficient of friction between 0.05 and 0.2, PTFE has one of the lowest friction values of any solid material.

Critically, its static and dynamic friction coefficients are nearly identical. This prevents the "stick-slip" motion common in other materials, ensuring smooth, continuous movement and drastically reducing surface wear in sliding applications like bearings or non-stick coatings.

Environmental and Chemical Resilience

Beyond its purely mechanical properties, PTFE's durability is defined by its near-total immunity to its surrounding environment.

Extreme Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This prevents the material degradation, swelling, or weakening that destroys other plastics over time.

This chemical stability ensures that its mechanical properties remain consistent even in the most corrosive environments.

Superior Weathering Resistance

PTFE is virtually unaffected by UV radiation, oxidation, moisture, and temperature extremes.

It does not become brittle or discolor with prolonged exposure to the elements, making it an exceptionally durable material for long-term outdoor applications.

Understanding the Trade-offs

To use PTFE effectively, it's critical to understand its limitations. Its unique strengths are balanced by notable weaknesses in other areas.

Low Hardness and Strength

PTFE is a relatively soft material, with a Shore D hardness of around 50-55. Its tensile strength is moderate, typically in the range of 20-35 MPa.

This means it is not suitable for applications that require high structural strength or resistance to being scratched or indented.

The Problem of Creep (Cold Flow)

One of the most significant limitations of PTFE is its tendency to creep, or permanently deform, under sustained pressure.

If a constant load is applied, a PTFE component will slowly change shape over time. This makes it unsuitable for high-load structural components unless its design is reinforced.

Poor Abrasion Resistance

While its low friction minimizes wear from smooth sliding, PTFE has low resistance to mechanical abrasion. Abrasive particles can easily wear away the material's surface.

This distinction is crucial: it resists wear from chemical attack and smooth sliding, but not from gritty, abrasive contact.

Making the Right Choice for Your Application

Selecting PTFE depends entirely on matching its unique profile to the demands of your project.

- If your primary focus is low-friction movement and chemical resistance: PTFE is an ideal choice for seals, gaskets, non-stick coatings, and bearings operating in corrosive environments.

- If your primary focus is high-load structural support: PTFE is unsuitable due to its low strength and tendency to creep under constant pressure.

- If your primary focus is resistance to mechanical abrasion: Virgin PTFE is not recommended; you should consider either a different material or a filled grade of PTFE designed for higher wear resistance.

By understanding this balance of elite performance and specific limitations, you can leverage PTFE's unique durability for applications that demand resilience against extreme conditions.

Summary Table:

| Key Property | Value/Range | Impact on Durability |

|---|---|---|

| Elongation at Break | 200% - 400% | Extreme flexibility; absorbs stress without cracking |

| Coefficient of Friction | 0.05 - 0.2 | Minimizes surface wear in sliding applications |

| Chemical Resistance | Resistant to nearly all chemicals | Prevents degradation in harsh environments |

| Impact Strength (Izod) | ~160 J/m | Absorbs shocks without fracturing |

| Key Limitation: Creep | Susceptible to deformation under sustained load | Unsuitable for high-load structural parts |

Need a Durable PTFE Component for Your Demanding Application?

KINTEK specializes in manufacturing high-precision PTFE components—from seals and liners to custom labware—that leverage these unique mechanical properties for superior performance. Our expertise ensures your parts deliver exceptional chemical resistance, low friction, and flexibility, precisely tailored for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Custom Fabrication: From prototypes to high-volume orders.

- Material Expertise: Optimal selection for your specific environmental and mechanical demands.

- Precision Production: Consistent quality for reliable, long-lasting performance.

Contact us today to discuss how our PTFE solutions can enhance the durability and efficiency of your equipment. Let's engineer resilience together.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are PTFE lined pipes and where are they used? A Complete Guide to Corrosion-Resistant Piping

- What determines the lifespan of a PTFE coating thrust washer in a fishing reel? Maximize Durability & Performance

- Are PTFE encapsulated O-rings compliant with industry standards? Ensure Purity & Performance in Critical Applications

- How do PTFE expansion bellows contribute to cost savings in power plants? Slash Maintenance and Downtime Costs

- What is the function of check valves in water pump systems? Protect Your Pump and Prevent Backflow

- How have PTFE coatings transformed the food processing industry? Boosting Efficiency, Safety & Profitability

- How does the non-stick surface of Teflon sheets benefit heat transfer projects? Achieve Flawless, Professional Results

- Can a Teflon sheet be used for sublimation printing? Enhance Print Quality & Protect Equipment