At their core, PTFE expansion bellows contribute significant cost savings in power plants by drastically reducing maintenance needs, preventing catastrophic failures that lead to expensive downtime, and protecting surrounding equipment from damage. Their inherent durability and chemical resistance mean they last longer and perform more reliably than alternative materials, directly lowering long-term operational expenditures.

The primary financial advantage of PTFE expansion bellows is not their purchase price, but their ability to lower the total cost of ownership. By investing in a highly reliable component, power plants mitigate the far greater expenses associated with maintenance, downtime, and system-wide repairs.

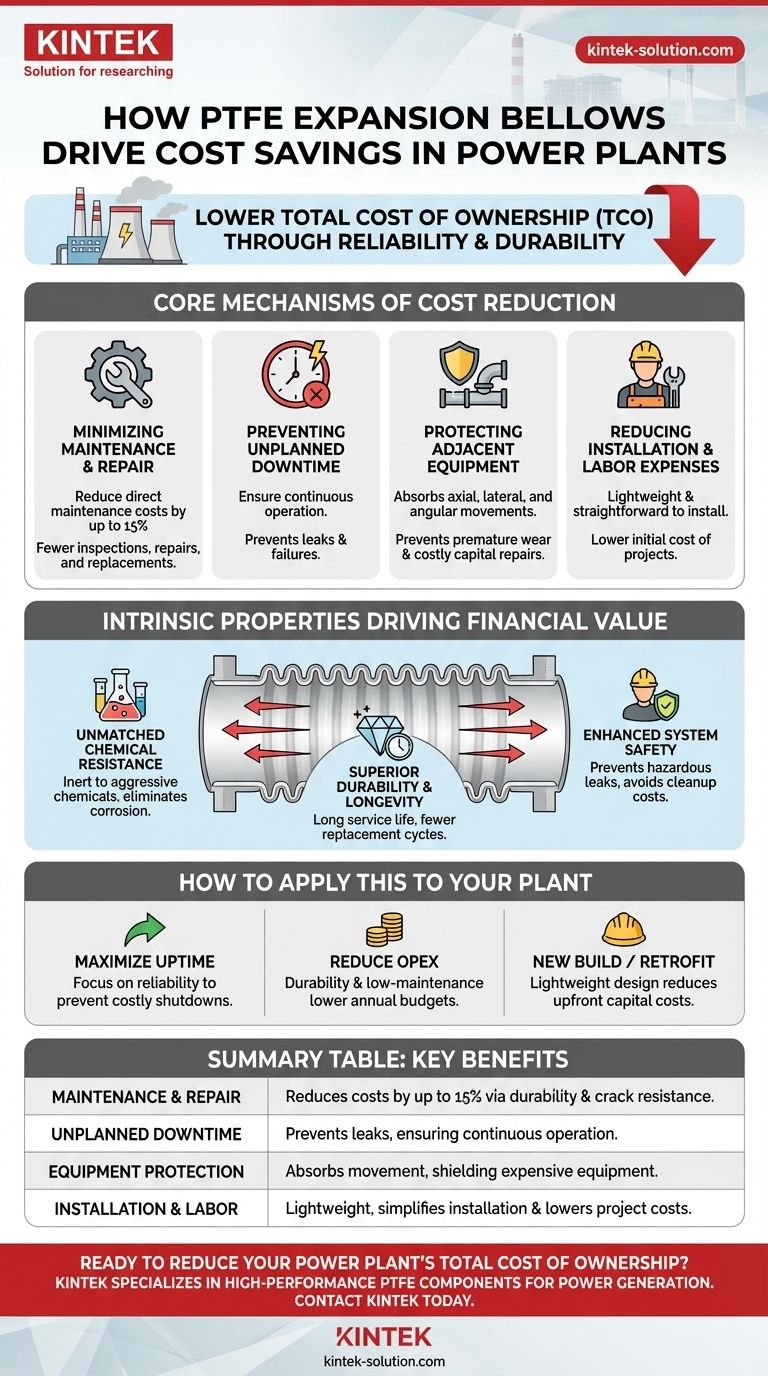

The Core Mechanisms of Cost Reduction

The financial benefits of PTFE bellows stem from their direct impact on a plant's operational budget and efficiency. They solve common and costly engineering challenges inherent to power generation environments.

Minimizing Maintenance and Repair Costs

PTFE's exceptional toughness and resistance to stressors prevent the formation of stress-induced cracks. This inherent durability can reduce direct maintenance costs by up to 15% by minimizing the need for frequent inspections, repairs, and component replacements.

Preventing Unplanned Downtime

In a power plant, downtime is the single most significant source of financial loss. By reliably preventing leaks and component failures, PTFE bellows ensure the continuous operation of critical systems like cooling, exhaust, and chemical dosing pipelines. A 90% reduction in leakage, as seen in similar industrial applications, translates directly to maximized operational availability.

Protecting Adjacent Equipment

Power plant systems are subject to constant vibration and thermal expansion. PTFE bellows are highly flexible, effectively absorbing axial, lateral, and angular movements. This shock absorption protects expensive and sensitive equipment connected to the pipeline, preventing premature wear and costly capital repairs.

Reducing Installation and Labor Expenses

Compared to heavier, more rigid alternatives, PTFE expansion bellows are lightweight and straightforward to install. This simplicity reduces the man-hours and specialized equipment needed for installation, lowering the initial cost of both new construction and retrofit projects.

Intrinsic Properties Driving Financial Value

The cost savings are not accidental; they are a direct result of the fundamental material properties of Polytetrafluoroethylene (PTFE).

Unmatched Chemical Resistance

Power plants utilize a range of aggressive chemicals in processes like water treatment and emissions control. PTFE is nearly chemically inert, meaning it will not degrade or corrode when exposed to these substances. This eliminates a common failure point seen in materials like rubber, extending the component's service life indefinitely.

Superior Durability and Longevity

The material's toughness and environmental stability ensure a long service life with minimal degradation. This longevity means fewer replacement cycles over the life of the power plant, deferring capital spending and reducing the total cost of ownership.

Enhanced System Safety

The reliability of PTFE bellows directly enhances worker safety. By preventing leaks of hazardous materials, plants avoid the significant costs associated with cleanup, regulatory fines, and potential accidents, creating a more secure and cost-effective operational environment.

How to Apply This to Your Plant

Your specific goal will determine which benefit is most critical for your application.

- If your primary focus is maximizing uptime: The key advantage is the material's proven reliability in preventing leaks and failures that cause costly shutdowns.

- If your primary focus is reducing operational expenditures (OpEx): The durability and low-maintenance nature of PTFE directly lower annual budgets for repairs, labor, and component replacement.

- If your primary focus is a new build or retrofit project: The lightweight design and simple installation process reduce upfront capital costs and shorten project timelines.

Ultimately, specifying PTFE expansion bellows is an investment in operational stability and long-term financial predictability.

Summary Table:

| Cost Saving Area | Key Benefit of PTFE Bellows |

|---|---|

| Maintenance & Repair | Reduces costs by up to 15% via superior durability and crack resistance. |

| Unplanned Downtime | Prevents leaks and failures, ensuring continuous operation and revenue. |

| Equipment Protection | Absorbs movement and vibration, shielding expensive adjacent equipment. |

| Installation & Labor | Lightweight design simplifies installation, lowering project costs. |

Ready to reduce your power plant's total cost of ownership?

KINTEK specializes in manufacturing high-performance, custom PTFE components like expansion bellows for the demanding environments of the power generation industry. Our bellows are engineered for maximum durability and chemical resistance to directly lower your maintenance costs and prevent expensive downtime.

Contact KINTEK today to discuss how our precision PTFE solutions can protect your critical systems and improve your bottom line.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries