At its core, PTFE coatings have fundamentally transformed the food processing industry by introducing a unique combination of non-stick, chemically inert, and heat-resistant properties. This trifecta solved long-standing challenges related to production efficiency, food safety, and product quality, moving the industry toward higher standards of hygiene and automation.

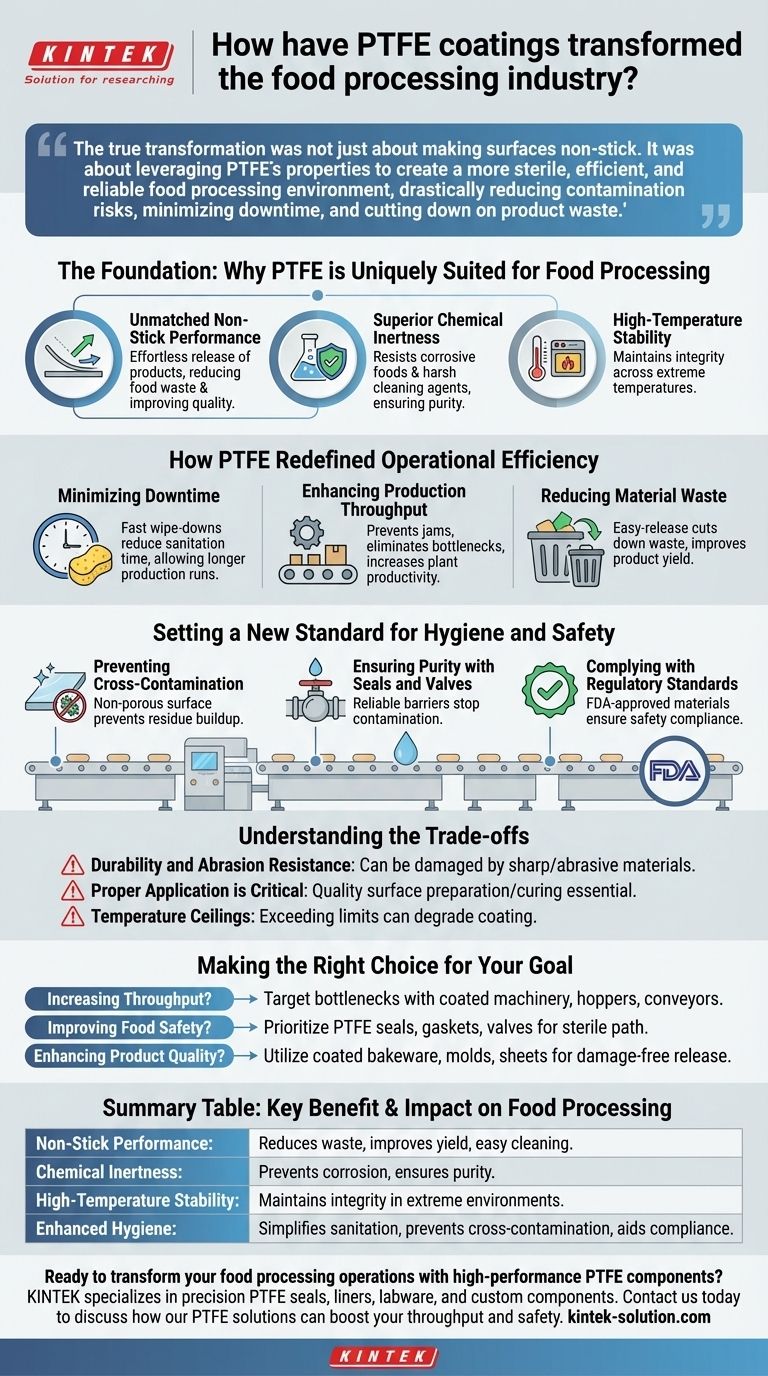

The true transformation was not just about making surfaces non-stick. It was about leveraging PTFE's properties to create a more sterile, efficient, and reliable food processing environment, drastically reducing contamination risks, minimizing downtime, and cutting down on product waste.

The Foundation: Why PTFE is Uniquely Suited for Food Processing

To understand PTFE's impact, we must first look at its three defining characteristics. These properties work in concert to solve multiple problems simultaneously.

Unmatched Non-Stick Performance

The most well-known feature of PTFE is its extremely low coefficient of friction, making its surface exceptionally non-stick.

In applications like bakeware or conveyor belts, this ensures the effortless release of products. This seemingly simple benefit directly reduces food waste and improves the final quality by preventing damage.

Superior Chemical Inertness

Food products can be highly acidic or alkaline, which can corrode machinery and contaminate the food itself.

PTFE is almost completely chemically inert, meaning it does not react with corrosive foods or harsh cleaning agents. This makes it an ideal material for seals, valves, and packings, ensuring the purity of the food product.

High-Temperature Stability

Food processing often involves extreme temperatures, from high-heat baking to flash-freezing.

PTFE maintains its integrity and properties across a wide temperature range. This allows PTFE-coated sheets and transport belts to be used reliably in ovens and other high-temperature environments without degrading.

How PTFE Redefined Operational Efficiency

The introduction of PTFE moved operations away from mechanical scraping and frequent production stops. This shift unlocked a new level of productivity and reliability.

Minimizing Downtime with Easy Cleaning

Before PTFE, cleaning sticky residue from machinery was a time-consuming, labor-intensive process that required significant downtime.

PTFE's non-stick surface allows for fast and simple wipe-downs, dramatically reducing the time and effort needed for sanitation. This allows production lines to run for longer with fewer interruptions.

Enhancing Production Throughput

On high-speed packaging and processing lines, any adherence of materials can cause a jam, halting the entire operation.

By coating machinery components, guides, and belts with PTFE, sticky substances like sugars and adhesives flow smoothly. This eliminates a common bottleneck and increases overall plant productivity.

Reducing Material Waste

In processes like baking or confectionery production, product that sticks to surfaces is often damaged and must be discarded.

The easy-release nature of PTFE-coated surfaces ensures that virtually all of the product is usable, significantly cutting down on material waste and improving yield.

Setting a New Standard for Hygiene and Safety

Perhaps the most critical transformation has been in food safety. PTFE's properties make it easier for facilities to meet and exceed stringent hygiene regulations.

Preventing Cross-Contamination

The non-porous, smooth surface of PTFE prevents food residue from becoming trapped, which can harbor bacteria.

Thorough and effective cleaning after each batch is simplified, which is critical for preventing cross-contamination between different food products and ensuring compliance.

Ensuring Purity with Seals and Valves

Mixers, pumps, and fluid transport systems are potential points of contamination.

PTFE rotary shaft seals and valve components create a reliable barrier that prevents lubricants or other processing fluids from entering the food supply. Their chemical inertness also ensures they don't leach any substances into the product.

Complying with Regulatory Standards

Materials used in food processing equipment must meet strict safety guidelines.

Many grades of PTFE are FDA-approved for direct food contact. Using components like PTFE extruded rods for machinery parts helps manufacturers ensure their equipment complies with health and safety regulations.

Understanding the Trade-offs

While transformative, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Durability and Abrasion Resistance

PTFE coatings, while durable, can be damaged by sharp utensils or abrasive materials. Scratches can compromise the non-stick surface and create areas where bacteria could potentially collect.

Proper Application is Critical

The performance and longevity of a PTFE coating are highly dependent on the quality of its application. Improper surface preparation or curing can lead to premature failure of the coating.

Temperature Ceilings

Although it has high heat resistance, PTFE does have an upper temperature limit. Exceeding this can cause the coating to degrade, so it is critical to use it within its specified operational range.

Making the Right Choice for Your Goal

Strategically applying PTFE can directly address specific operational challenges and deliver a measurable return on investment.

- If your primary focus is increasing throughput: Target bottlenecks caused by sticking. Use PTFE coatings on packaging machinery, hoppers, and conveyor systems.

- If your primary focus is improving food safety: Prioritize points of potential contamination. Implement PTFE seals, gaskets, and valve components to ensure a sterile and inert processing path.

- If your primary focus is enhancing product quality and yield: Focus on surfaces in direct contact with the final product. Utilize PTFE-coated bakeware, molds, and cooking sheets for consistent, damage-free release.

By understanding its core benefits and applying it strategically, you can leverage PTFE to elevate nearly every aspect of food production, from safety to profitability.

Summary Table:

| Key Benefit | Impact on Food Processing |

|---|---|

| Non-Stick Performance | Reduces product waste, improves yield, and enables easy cleaning. |

| Chemical Inertness | Prevents corrosion and contamination, ensuring product purity. |

| High-Temperature Stability | Maintains integrity in ovens and extreme environments. |

| Enhanced Hygiene | Simplifies sanitation, prevents cross-contamination, and aids regulatory compliance. |

Ready to transform your food processing operations with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the food processing, semiconductor, medical, and laboratory industries. Whether you need prototypes or high-volume orders, our custom fabrication ensures your equipment meets the highest standards of efficiency and safety.

Contact us today to discuss how our PTFE solutions can boost your throughput, enhance food safety, and improve your bottom line.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE superior in terms of chemical resistance compared to rubber seals? The Key to Unmatched Reliability

- What are the primary applications of PTFE PCBs? The Ultimate Guide for High-Frequency & Harsh Environments

- What are the main benefits of PTFE lined butterfly valves? Superior Performance for Corrosive & High-Purity Media

- What are the standard gasket choices for PTFE rotary lip seals? Ensure Total System Reliability

- What industries commonly use machined PTFE parts? Key Applications in Aerospace, Medical, and Semiconductor

- What are the material properties of PTFE relevant to CNC machining? Mastering Softness & Heat for Precision

- What temperature range can PTFE flange gaskets withstand? From Cryogenic -200°C to High-Temp +260°C

- Why is virgin PTFE particularly suitable for food and medical applications? Ensuring Purity and Safety