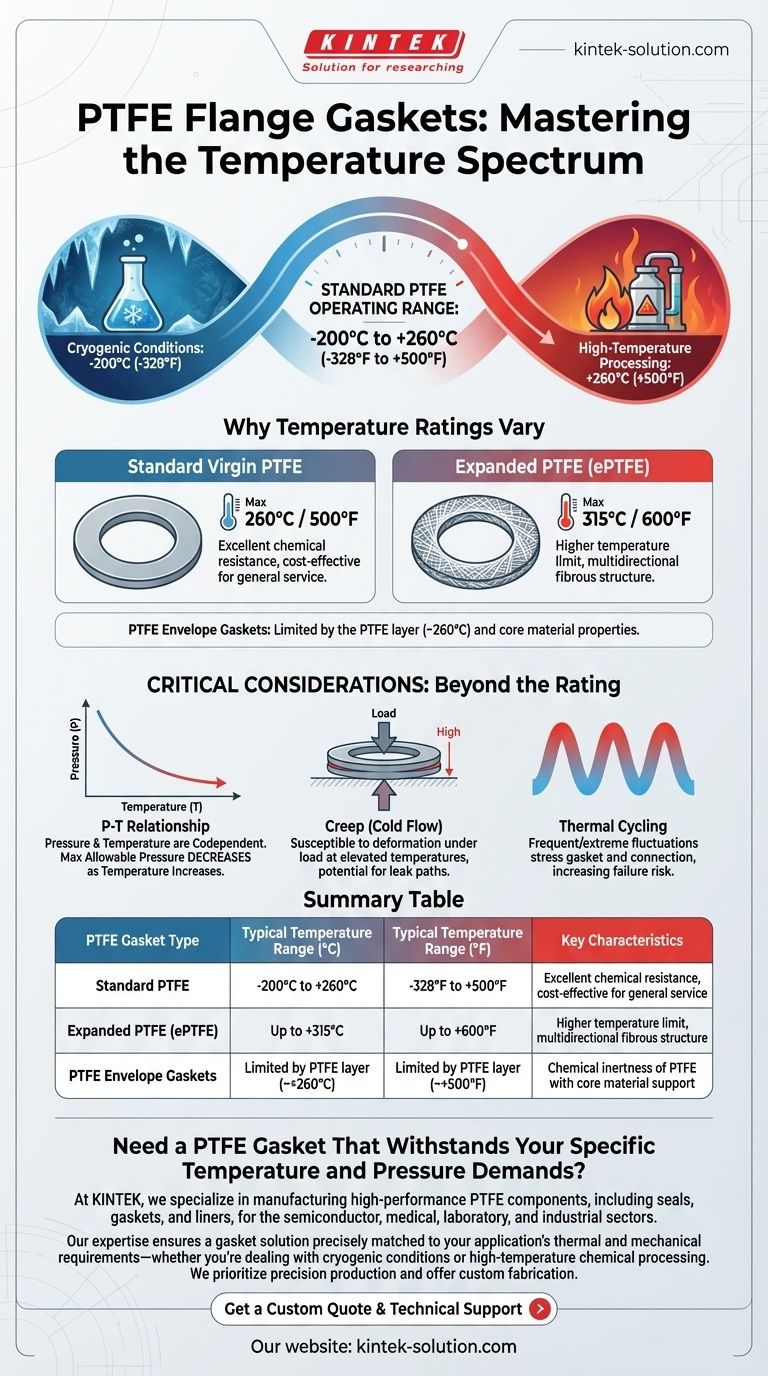

In short, standard PTFE flange gaskets can reliably withstand a temperature range from -200°C to +260°C (-328°F to +500°F). This exceptional thermal stability makes them suitable for a vast array of applications, from cryogenic processes to high-temperature chemical processing.

The specific temperature rating of a PTFE gasket is not a single, universal value. It depends heavily on the type of PTFE used (e.g., standard vs. expanded) and the operational pressure, as these two factors are intrinsically linked.

Understanding the Baseline: Standard PTFE

The Standard Operating Range

For "virgin" or standard Polytetrafluoroethylene (PTFE), the widely accepted service temperature range is -200°C to +260°C (-328°F to +500°F). Within this window, the material maintains its critical properties.

Performance at High Temperatures

Up to 260°C (500°F), PTFE retains its excellent chemical resistance and structural integrity. It resists breaking down or degrading, ensuring a stable and reliable seal in demanding, hot environments common in chemical and energy sectors.

Performance in Cryogenic Conditions

At the low end of the spectrum, PTFE excels. Unlike many materials that become brittle and fail at extremely low temperatures, PTFE remains flexible and effective down to -200°C (-328°F), making it a prime choice for cryogenic applications.

Why You See Different Temperature Ratings

You will often see different temperature limits cited for "PTFE" gaskets. This variation is not an error; it reflects the existence of different formulations and types of PTFE gaskets designed for specific performance goals.

Expanded PTFE (ePTFE)

Expanded PTFE is manufactured differently to create a multidirectionally fibrous structure. This form of PTFE often has a higher temperature limit, with some gaskets rated for continuous operation up to 315°C (600°F).

PTFE Envelope Gaskets

These gaskets combine a core material (like rubber or a compressed fiber sheet) with a thin "envelope" of PTFE. While they provide the chemical inertness of PTFE, their temperature rating is ultimately governed by the weaker of the two materials—which is often the PTFE layer's standard 260°C limit.

Understanding the Trade-offs and Risks

A temperature rating is not an absolute guarantee of performance under all conditions. As a technical advisor, I must emphasize that temperature and pressure are codependent variables.

The Critical "P-T" Relationship

Manufacturers provide Pressure-Temperature (P-T) charts for their gaskets. A gasket cannot withstand its maximum rated pressure and maximum rated temperature simultaneously. As the temperature of the system increases, the maximum allowable pressure the gasket can seal decreases.

The Risk of Creep (Cold Flow)

PTFE is a thermoplastic, and at elevated temperatures, it softens. This makes it more susceptible to creep, or cold flow, where the material slowly deforms under the compressive load of the flange bolts. This can lead to a loss of bolt torque and a potential leak path over time, especially near the upper temperature limit.

The Impact of Thermal Cycling

PTFE is excellent at handling temperature fluctuations. However, frequent and extreme thermal cycles near the material's operational limits can repeatedly stress the gasket and connection, increasing the long-term risk of a seal failure.

Making the Right Choice for Your Application

To ensure a safe and reliable sealed joint, you must select the gasket based on your specific operational parameters.

- If your primary focus is general service below 260°C (500°F): Standard virgin PTFE offers a cost-effective and highly reliable sealing solution.

- If your application requires performance above 260°C (500°F): You must specify and source an Expanded PTFE (ePTFE) gasket and confirm its rating with the manufacturer.

- If your system involves both high pressure and high temperature: Always consult the manufacturer’s P-T chart to verify that your operating point is within the gasket’s safe performance envelope.

- If your process involves cryogenic temperatures: Standard PTFE is an exceptional choice due to its robust performance and resistance to low-temperature embrittlement.

Choosing the correct gasket is about matching the material's proven capabilities to the specific demands of your application.

Summary Table:

| PTFE Gasket Type | Typical Temperature Range (°C) | Typical Temperature Range (°F) | Key Characteristics |

|---|---|---|---|

| Standard PTFE | -200°C to +260°C | -328°F to +500°F | Excellent chemical resistance, cost-effective for general service |

| Expanded PTFE (ePTFE) | Up to +315°C | Up to +600°F | Higher temperature limit, multidirectional fibrous structure |

| PTFE Envelope Gaskets | Limited by PTFE layer (~+260°C) | Limited by PTFE layer (~+500°F) | Chemical inertness of PTFE with core material support |

Need a PTFE Gasket That Withstands Your Specific Temperature and Pressure Demands?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, gaskets, and liners, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures that you get a gasket solution precisely matched to your application's thermal and mechanical requirements—whether you're dealing with cryogenic conditions or high-temperature chemical processing.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring optimal performance and reliability in your critical sealing applications.

Contact us today to discuss your specific needs and let our experts help you select or design the perfect PTFE gasket for your system.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is PTFE used in medical applications? The Key to Biocompatible, Low-Friction Devices

- What are the advantages of using PTFE in plain bearings? Achieve Maintenance-Free, High-Performance Operation

- What role do fillers play in structured PTFE? Enhancing Strength, Wear, and Thermal Performance

- What materials are used in spring energized Teflon seals? A Guide to PTFE Jackets & Metal Springs

- What tools and techniques are recommended for machining PTFE? Achieve Precision and a Clean Finish

- In what types of environments are PTFE seat butterfly valves most suitable? Ideal for Corrosive, High-Purity Applications

- How does PTFE laminate differ from FR4 in terms of environmental and chemical resistance? Superior Stability for Harsh Conditions

- In what applications are PTFE balls commonly used? Key Uses in Chemical, Medical & Industrial Systems