The fundamental superiority of PTFE's chemical resistance stems from its unique molecular structure. The bonds between its carbon and fluorine atoms are exceptionally strong and stable, creating a non-reactive surface that is nearly impervious to chemical attack. In contrast, rubber (elastomer) seals are composed of more complex and less stable polymer chains, leaving them vulnerable to degradation from a wide range of specific chemicals.

The core difference is simple: PTFE is chemically inert by nature, making it a near-universal solution for aggressive environments. Rubber seals are chemically selective, meaning their resistance is limited to a specific list of compatible substances, requiring careful matching to the application to avoid failure.

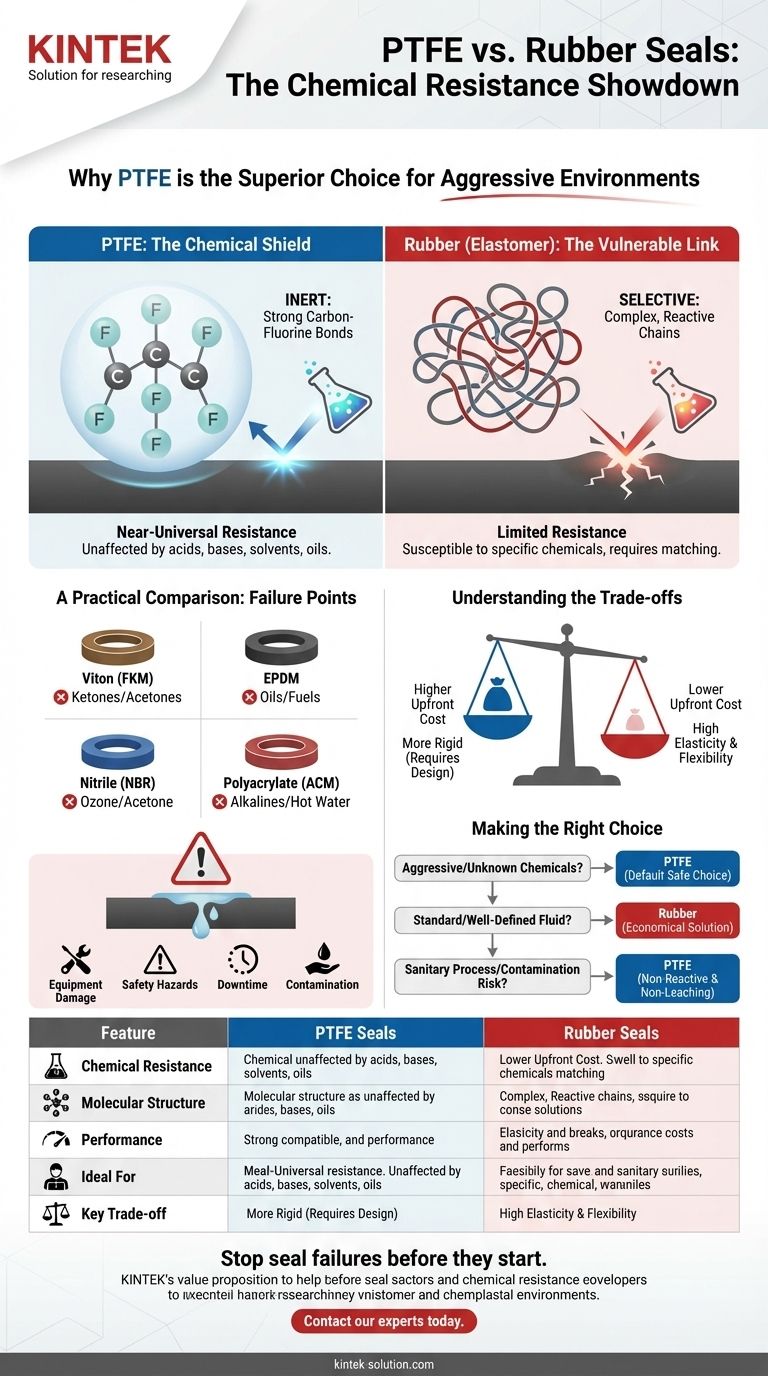

The Molecular Difference: Inert vs. Reactive

The choice between PTFE and rubber for a seal is not just a matter of performance, but a decision rooted in fundamental chemistry. One is built for universal defense, the other for specialized roles.

The Carbon-Fluorine Bond: PTFE's Chemical Armor

The backbone of a PTFE molecule is a chain of carbon atoms, each completely shielded by a sheath of fluorine atoms. The carbon-fluorine (C-F) bond is one of the strongest single bonds in organic chemistry.

This powerful bond makes the entire molecule incredibly stable and non-reactive. Most chemicals simply lack the energy to break it, causing them to slide past the PTFE surface without any interaction.

PTFE's Near-Universal Inertness

This molecular stability gives PTFE its legendary chemical resistance. It remains completely unaffected by highly corrosive substances like concentrated sulfuric, nitric, and hydrochloric acids, even when boiling.

It resists strong bases, oxidizers, solvents, and oils. The only common exception to PTFE's inertness is its reaction to molten alkali metals, a condition rarely found in typical industrial applications.

Rubber's Selective Resistance

Rubber compounds, or elastomers, have a more complex and exposed molecular structure. While they are engineered for excellent physical properties like elasticity, this very structure creates points of vulnerability.

Chemicals can attack the polymer chains, causing the material to swell, soften, harden, or dissolve completely. This is why rubber compatibility must be carefully verified for every specific chemical it will encounter.

A Practical Comparison of Common Seal Materials

The theoretical difference in chemical structure leads to starkly different outcomes in real-world applications. A chemical that is harmless to one type of seal can be catastrophic for another.

Failure Points of Common Elastomers

Different rubber compounds are formulated for different jobs, but each has a list of chemical weaknesses.

- Viton (FKM): While good with many fuels, it is highly susceptible to ketones and acetones.

- EPDM: Performs well with water and steam but fails quickly when exposed to most oils, fuels, and hydrocarbons.

- Nitrile (NBR): A common choice for oil resistance, but it is incompatible with ozone, acetone, esters, and ethers.

- Polyacrylate (ACM): Offers good resistance to hot oil but does not fare well with alkalines or hot water.

The Consequence of Chemical Attack

When a rubber seal is exposed to an incompatible substance, it begins to break down. This chemical deterioration leads directly to seal failure.

The result is leaks, which can cause equipment damage, create safety hazards, and lead to costly downtime. In sensitive processes like food or pharmaceutical production, a dissolving seal also poses a significant risk of product contamination.

Understanding the Trade-offs

While PTFE is the undisputed champion of chemical resistance, it is not the automatic choice for every application. A true technical decision requires weighing all material properties.

Beyond Chemical Resistance

The primary advantage of rubber seals is their elasticity and flexibility. They can conform to imperfect surfaces and provide a strong seal with less compressive force, which is ideal for many standard-pressure applications.

PTFE, being a more rigid material, often requires specific seal designs (like spring-energizing) to provide the same level of dynamic sealing performance as a flexible elastomer.

The Cost of Failure vs. The Cost of Material

PTFE seals typically have a higher upfront cost than common rubber seals. However, this initial expense must be weighed against the total cost of ownership.

In an application involving aggressive chemicals, the cost of a single leak caused by a failed rubber seal—in terms of machine damage, lost product, and cleanup—can easily exceed the cost of an entire system's worth of highly reliable PTFE seals.

Making the Right Choice for Your Application

Selecting the correct seal material is not about choosing the "best" material, but the right material for the specific demands of your operating environment.

- If your primary focus is handling aggressive, mixed, or unknown chemicals: PTFE is the default safe choice due to its near-universal inertness and predictable performance.

- If your primary focus is a standard application with a well-defined fluid (like hydraulic oil): A specialized rubber like Nitrile or Viton can be a highly effective and economical solution.

- If your primary focus is preventing product contamination in a sanitary process: PTFE's non-reactive and non-leaching properties make it the ideal choice for food, beverage, and pharmaceutical industries.

Ultimately, a thorough understanding of the chemical environment is the critical first step in selecting a seal that ensures safety, reliability, and long-term performance.

Summary Table:

| Feature | PTFE Seals | Rubber Seals |

|---|---|---|

| Chemical Resistance | Near-universal inertness | Selective, varies by compound |

| Molecular Structure | Strong C-F bonds, inert backbone | Complex, vulnerable polymer chains |

| Performance | Resists acids, bases, solvents, oils | Fails with incompatible chemicals |

| Ideal For | Aggressive, mixed, or unknown chemicals | Well-defined, compatible fluids |

| Key Trade-off | Higher upfront cost, less elasticity | Lower cost, excellent flexibility |

Stop seal failures before they start.

When your application demands reliability in the face of aggressive chemicals, the choice is clear. PTFE's inherent inertness provides a level of security that selective rubber compounds cannot match.

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with custom fabrication capabilities, from prototypes to high-volume orders, ensuring you get a seal engineered for your exact needs.

Protect your process, equipment, and product integrity. Contact our experts today to discuss your specific chemical resistance challenges and find the optimal PTFE solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions