At its core, virgin Polytetrafluoroethylene (PTFE) is uniquely suitable for food and medical applications because it is chemically inert, biocompatible, and non-toxic. This fundamental purity means it will not react with or contaminate the sensitive materials it touches, a property backed by its widespread FDA approval and exceptional physical stability.

The crucial insight is that PTFE's value in these sensitive fields goes beyond its famous non-stick surface. Its suitability is rooted in its molecular stability—it does not leach chemicals, trigger biological reactions, or degrade when exposed to aggressive cleaning agents or bodily fluids.

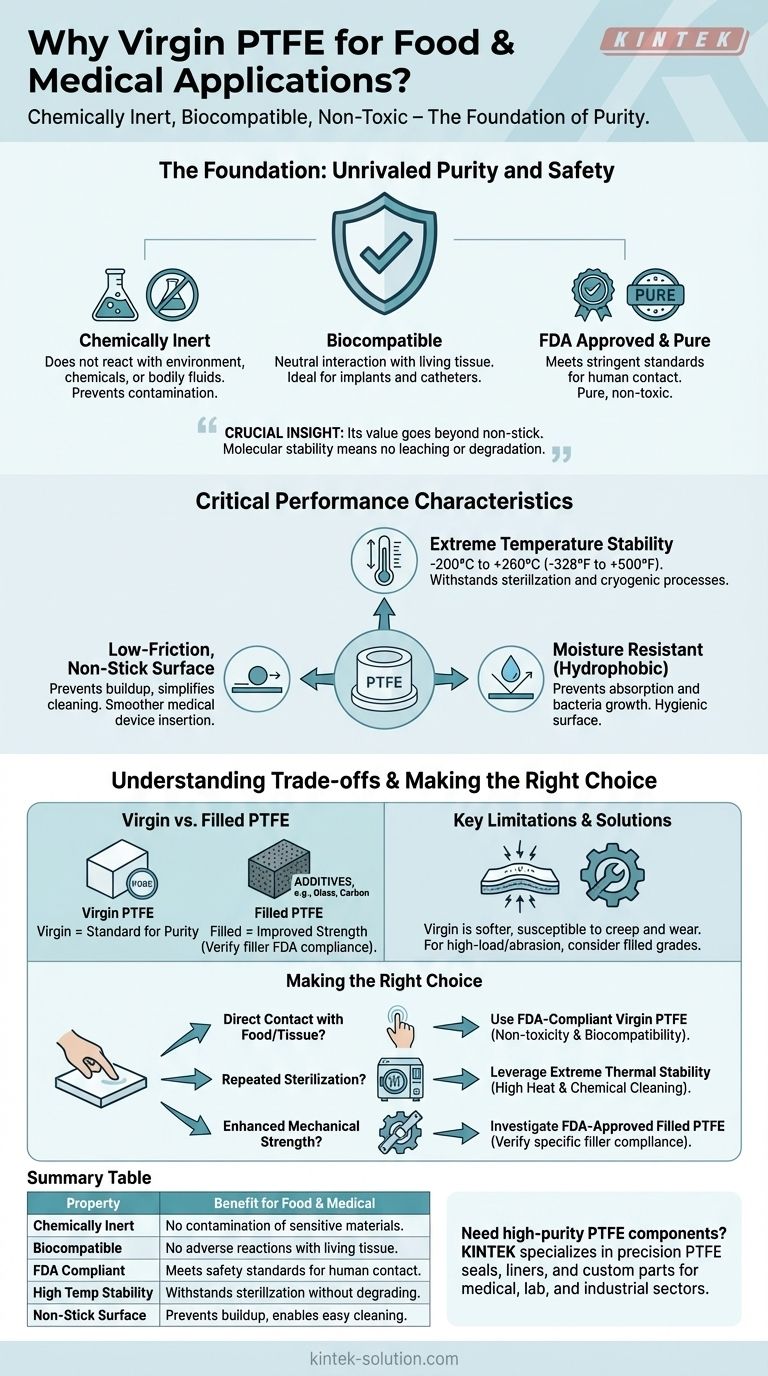

The Foundation: Unrivaled Purity and Safety

The suitability of PTFE for high-stakes applications is not based on a single feature, but on a combination of inherent properties that ensure safety and reliability.

What "Inert" Means in Practice

A material is chemically inert when it does not react with its environment. For PTFE, this means it is resistant to virtually all chemicals, acids, and bodily fluids.

This property prevents the material from degrading or breaking down, ensuring that no harmful substances are released into food, drugs, or the human body.

The Standard of Biocompatibility

Biocompatibility is the measure of how a material interacts with living tissue. Virgin PTFE is highly biocompatible, meaning it does not cause adverse reactions or immune responses.

This makes it a trusted material for medical implants, catheters, syringes, and surgical sutures, where interaction with the body must be completely neutral.

FDA Approval and Purity

Regulatory compliance is non-negotiable in these fields. Virgin PTFE, which is pure PTFE without any added fillers, meets stringent FDA standards for contact with food, beverages, and pharmaceuticals.

This approval serves as a third-party validation of its non-toxic and safe nature for human contact and consumption.

Critical Performance Characteristics

Beyond its chemical purity, PTFE possesses physical properties that make it highly effective in operational environments, from food processing plants to operating rooms.

Extreme Temperature Stability

PTFE maintains its core properties across an exceptionally wide temperature range, from -200°C to +260°C (-328°F to +500°F).

This thermal stability is critical for applications that require sterilization with high heat or use in cryogenic processes, as the material will not melt, deform, or become brittle.

The Low-Friction, Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. Its surface is non-stick and anti-adhesive.

In food processing, this prevents buildup and simplifies cleaning. In medical devices like catheters, this low-friction surface allows for smoother and safer insertion.

Resistance to Moisture

PTFE is hydrophobic, meaning it is highly resistant to water. This prevents moisture absorption, which can be a breeding ground for bacteria, ensuring a more hygienic surface.

Understanding the Trade-offs

While virgin PTFE is an exceptional material, it is essential to understand its specific limitations to use it effectively.

Virgin vs. Filled PTFE

Virgin PTFE is the standard for purity. However, filled grades of PTFE—which contain additives like glass, carbon, or minerals—are often used to improve mechanical properties like wear resistance and strength.

While some mineral-filled grades are also FDA compliant, it is critical to verify that both the PTFE and the specific filler meet the regulatory requirements for your exact application.

Key Mechanical Limitations

Virgin PTFE is a relatively soft material. It can be susceptible to creep (deformation under load) and has poor wear resistance compared to many other engineering plastics.

For high-load or high-abrasion applications, a different material or a specifically formulated filled PTFE may be necessary.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary objective.

- If your primary focus is direct contact with food or biological tissue: Ensure you are using FDA-compliant virgin PTFE to guarantee non-toxicity and biocompatibility.

- If your application requires repeated sterilization: PTFE's extreme thermal stability makes it an ideal choice for reliable components that can withstand high-heat or chemical cleaning cycles.

- If you need enhanced mechanical strength and FDA compliance: Investigate an FDA-approved filled PTFE, but rigorously verify that the specific filler material also meets all necessary regulatory standards.

Ultimately, selecting virgin PTFE provides a level of chemical purity and operational safety that is nearly unmatched for critical food and medical environments.

Summary Table:

| Property | Benefit for Food & Medical Applications |

|---|---|

| Chemically Inert | Will not react with or contaminate food, drugs, or bodily fluids. |

| Biocompatible | Does not cause adverse reactions with living tissue; ideal for implants. |

| FDA Compliant | Meets stringent standards for safety in direct human contact. |

| High Temp Stability | Withstands sterilization (up to 260°C / 500°F) without degrading. |

| Non-Stick Surface | Prevents material buildup and allows for easy, thorough cleaning. |

Need high-purity PTFE components for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the chemically inert, biocompatible, and FDA-compliant parts you need for uncompromising safety and performance.

Contact our experts today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE washers ideal for high and low temperature applications? Ensuring Reliable Performance in Extreme Environments

- What are the key features of custom Teflon parts? Unlock Chemical & Thermal Resistance

- How can the disadvantages of PTFE processing machines be mitigated? Manage Trade-offs for Optimal Performance

- In which industries are machined PTFE parts commonly used? Discover the Essential High-Performance Material

- What temperature range can PTFE O-rings withstand? Unlock Extreme Thermal Performance from -200°C to 260°C

- How do PTFE expansion bellows compare to rubber bellows in terms of chemical resistance? PTFE Offers Near-Universal Chemical Resistance

- Why is PTFE often used in electric actuated butterfly valves? Achieve Reliable, Automated Flow Control

- How does PTFE's hydrophobicity protect against corrosion? Build a Superior Moisture Barrier for Your Equipment