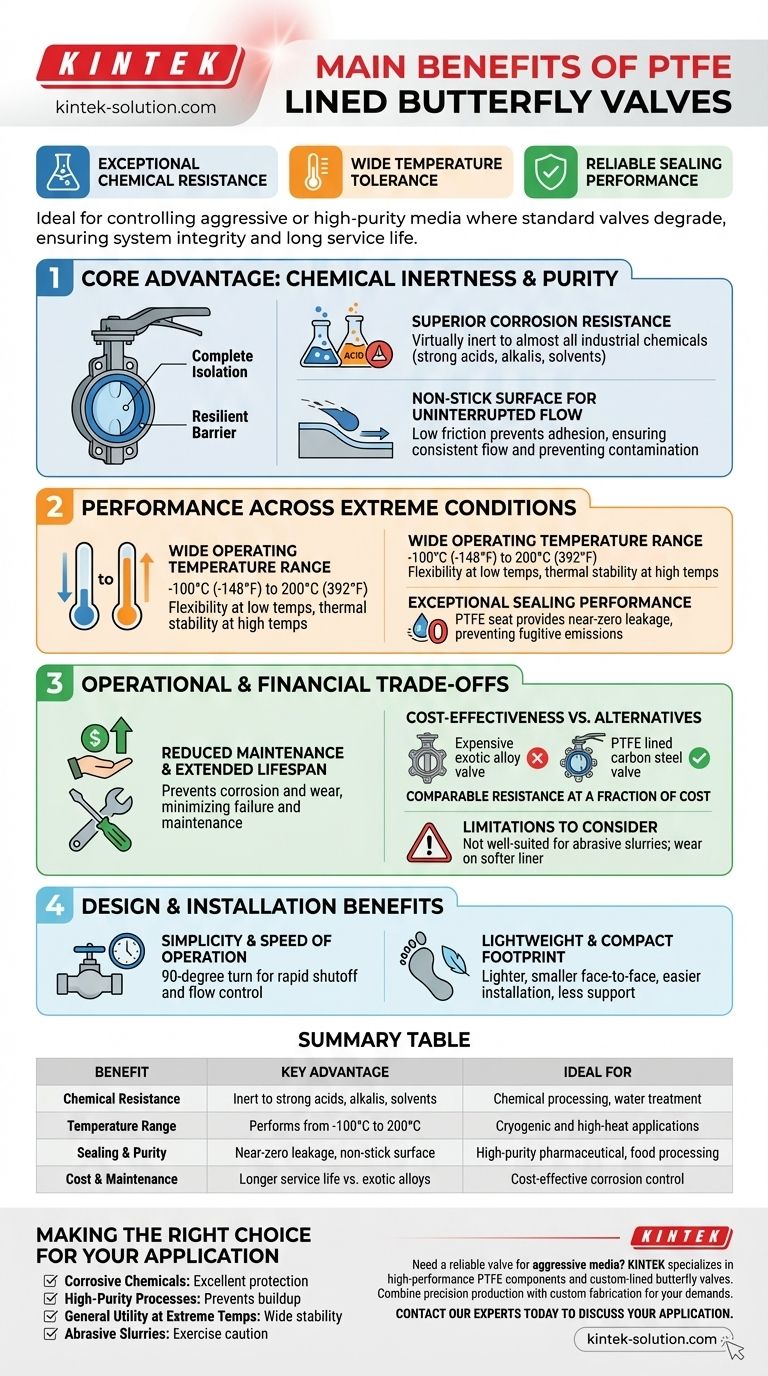

The primary benefits of PTFE lined butterfly valves are their exceptional chemical resistance, wide temperature tolerance, and reliable sealing performance. This combination makes them a superior choice for controlling aggressive or high-purity media where standard valves would quickly degrade, ensuring both system integrity and a long service life with minimal maintenance.

When designing systems for corrosive chemicals, extreme temperatures, or high-purity processes, material compatibility is the central challenge. PTFE lined butterfly valves solve this by combining the simple, efficient design of a butterfly valve with the near-universal inertness of a Polytetrafluoroethylene (PTFE) liner.

The Core Advantage: Chemical Inertness and Purity

The most significant benefit of a PTFE liner is the complete isolation of the valve body and stem from the process media. This creates a highly resilient barrier against chemical attack.

Superior Corrosion Resistance

PTFE is virtually inert to almost all industrial chemicals, including strong acids, alkalis, solvents, and oxidants. This makes it an ideal choice for harsh chemical processing, water treatment, and pharmaceutical applications where media can quickly corrode metal components.

Non-Stick Surface for Uninterrupted Flow

The surface of PTFE is extremely smooth and has a very low coefficient of friction, often referred to as "non-stick." This property prevents viscous or sticky media from adhering to the valve's internal surfaces, ensuring consistent flow and preventing contamination or buildup that could disrupt a process.

Performance Across Extreme Conditions

Beyond its chemical resilience, PTFE performs reliably across a wide spectrum of operating environments, from cryogenic lows to high-heat applications.

Wide Operating Temperature Range

PTFE liners maintain their integrity and performance characteristics over an exceptionally broad temperature range, typically from -100°C (-148°F) up to 200°C (392°F). The material remains soft and flexible at low temperatures and thermally stable at high temperatures, preventing it from becoming brittle or degrading.

Exceptional Sealing Performance

The design of these valves, with the PTFE seat providing a tight seal against the disc, allows for excellent shutoff capabilities. Many PTFE lined butterfly valves are rated for near-zero leakage, making them highly effective for isolating pipelines and preventing fugitive emissions.

Understanding the Operational and Financial Trade-offs

While the performance benefits are clear, it is the operational and financial advantages that often drive the decision to specify these valves.

Reduced Maintenance and Extended Lifespan

By preventing corrosion and media buildup, the PTFE liner directly minimizes the primary causes of valve wear and failure. This leads to a significantly longer service life and reduces the frequency and cost of maintenance interventions.

Cost-Effectiveness vs. Alternatives

For highly corrosive services, the alternative is often a valve constructed entirely from expensive exotic alloys. A PTFE lined valve, which can use a less expensive body material like carbon steel or ductile iron, provides comparable chemical resistance at a fraction of the cost.

Limitations to Consider

While extremely versatile, PTFE is a polymer, not a metal. It is not well-suited for services involving abrasive slurries, as hard particles can wear down the softer liner over time. For such applications, a metal-seated or specialized slurry valve may be a more durable choice.

Design and Installation Benefits

The inherent design of the butterfly valve, enhanced by the PTFE liner, offers practical advantages in system design and operation.

Simplicity and Speed of Operation

Butterfly valves are quarter-turn valves, meaning they go from fully open to fully closed with a 90-degree turn of the stem. This allows for rapid shutoff and straightforward flow control.

Lightweight and Compact Footprint

Compared to other valve types like gate or globe valves, butterfly valves are significantly lighter and have a much smaller face-to-face dimension. This makes them easier to install, especially in tight spaces, and reduces the need for costly pipe supports.

Making the Right Choice for Your Application

Selecting the correct valve hinges on matching its strengths to your primary operational goal.

- If your primary focus is handling corrosive chemicals: A PTFE lined valve is an excellent, cost-effective choice for protecting valve components and ensuring media purity.

- If your primary focus is high-purity or sanitary processes: The non-stick surface of PTFE prevents media buildup, making it ideal for applications in pharmaceuticals or food processing where cleanliness is critical.

- If your primary focus is general utility at extreme temperatures: The wide thermal stability of PTFE makes it a reliable option for both cryogenic and high-heat applications within its specified range.

- If your primary focus is managing abrasive slurries: You should exercise caution, as the softer PTFE lining may be susceptible to wear from abrasive particles, favoring a metal-seated or specialized valve instead.

By understanding these capabilities, you can confidently specify PTFE lined butterfly valves for demanding applications where reliability and chemical compatibility are non-negotiable.

Summary Table:

| Benefit | Key Advantage | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to strong acids, alkalis, and solvents | Chemical processing, water treatment |

| Temperature Range | Performs from -100°C to 200°C | Cryogenic and high-heat applications |

| Sealing & Purity | Near-zero leakage, non-stick surface | High-purity pharmaceutical, food processing |

| Cost & Maintenance | Longer service life vs. exotic alloys | Cost-effective corrosion control |

Need a reliable valve for aggressive media? KINTEK specializes in manufacturing high-performance PTFE components, including custom-lined butterfly valves, for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with custom fabrication from prototypes to high-volume orders to deliver the chemical resistance and reliability your process demands. Contact our experts today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability