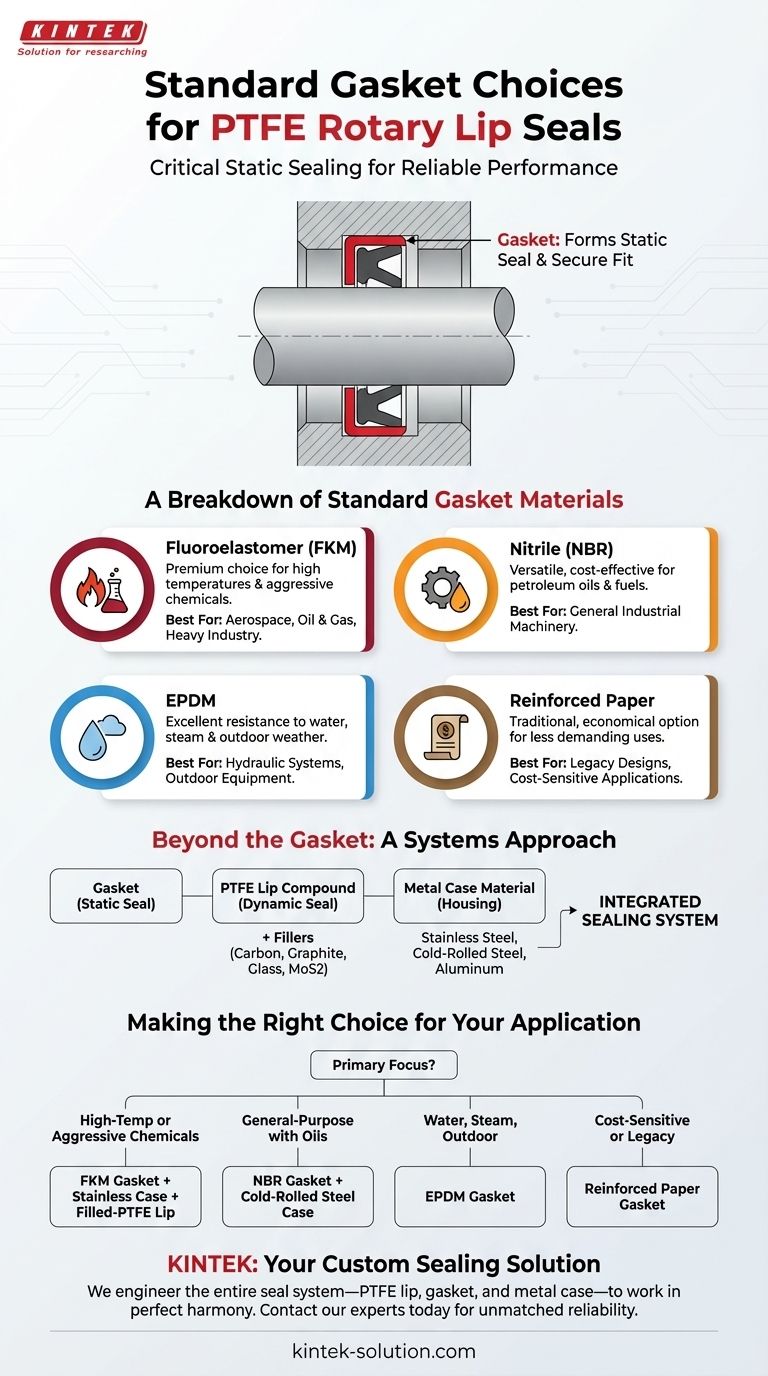

The standard gasket choices for PTFE rotary lip seals are fluoroelastomer (FKM), nitrile (NBR), EPDM, and Armstrong reinforced paper. These materials are selected for their ability to create a reliable static seal between the outer case of the lip seal and the housing bore, complementing the dynamic sealing performance of the PTFE lip itself.

The gasket on a PTFE rotary seal is a critical but often overlooked component. Selecting the right one requires looking beyond the gasket itself and viewing the seal as a complete system, where the gasket, the PTFE lip material, and the metal case must work in concert to meet the specific temperature, chemical, and environmental demands of your application.

The Role of the Gasket in a PTFE Seal

While the PTFE lip handles the dynamic sealing against the rotating shaft, the gasket performs a crucial static function. It is positioned on the outer diameter of the seal's metal case.

Preventing External Leakage

The primary job of the gasket is to form a tight, static seal against the machined housing bore. This prevents the sealed media from leaking around the outside of the seal assembly.

Ensuring a Secure Fit

The gasket compensates for minor imperfections in the housing bore's surface finish. Its compressibility ensures a press-fit that holds the seal securely in place and prevents external contaminants like dirt or moisture from entering the system.

A Breakdown of Standard Gasket Materials

Each standard gasket material offers a unique profile of resistance and performance, making it suitable for different operating environments.

Fluoroelastomer (FKM)

FKM is the premium choice for demanding applications. It offers excellent resistance to high temperatures and a broad range of aggressive chemicals, fuels, and oils, making it common in aerospace, oil and gas, and heavy-duty industrial machinery.

Nitrile (NBR)

Nitrile is the versatile workhorse of sealing. It provides a reliable and cost-effective solution for general-purpose applications involving petroleum-based oils and fuels, making it a default choice for a wide array of industrial equipment.

EPDM

EPDM excels in applications involving water, steam, brake fluids, or where significant outdoor weather and ozone exposure is expected. However, it generally has poor resistance to petroleum-based oils and solvents.

Armstrong Reinforced Paper

This is a traditional, cost-effective gasket material. It consists of a fibrous paper base reinforced for durability and is typically used in less demanding applications or in specific gearbox designs where it has historically been the standard.

Beyond the Gasket: A Systems Approach to Seal Selection

A design engineer must consider how the gasket, PTFE lip, and metal case function together as an integrated system.

The PTFE Lip Compound

The PTFE lip itself can be customized. While virgin PTFE is used, it is often blended with fillers like carbon, graphite, glass, or Molybdenum Disulfide (MoS2). These fillers enhance properties like wear resistance, thermal conductivity, and resistance to deformation under load.

The Metal Case Material

The choice of the seal's housing or case is dictated by cost and corrosion concerns.

- Stainless steel provides maximum corrosion resistance for food, pharmaceutical, or chemical processing.

- Cold-rolled steel (often zinc-plated) offers a strong, cost-effective solution for general industrial use.

- Aluminum can be used where weight is a primary concern.

Understanding the Trade-offs

Choosing the right seal assembly involves balancing performance against cost and understanding material limitations.

Cost vs. Performance

A seal with a stainless steel case, an FKM gasket, and a carbon-filled PTFE lip offers exceptional performance in harsh environments but comes at a significant cost. Conversely, a zinc-plated steel case with a nitrile gasket is far more economical but has a narrower operating window.

Chemical and Thermal Limitations

No single material is universally compatible. An EPDM gasket that is perfect for a hot water system will fail quickly if exposed to gasoline. An FKM gasket may be ideal for high temperatures but could be incompatible with certain aggressive acids or ketones.

Installation Sensitivity

The effectiveness of the outer gasket relies on a properly prepared housing bore. A surface that is too rough can create leak paths, while one that is too smooth may not provide enough friction to retain the seal under pressure.

Making the Right Choice for Your Application

Your final selection should be driven by the specific demands of your operating environment.

- If your primary focus is high-temperature or aggressive chemical sealing: Choose a fluoroelastomer (FKM) gasket, likely paired with a stainless steel case and a specialized filled-PTFE lip.

- If your primary focus is general-purpose industrial use with oils: A nitrile (NBR) gasket with a cold-rolled steel case is the standard, cost-effective choice.

- If your primary focus is sealing water, steam, or outdoor applications: Select an EPDM gasket, ensuring it is compatible with any lubricants present in the system.

- If your primary focus is a cost-sensitive or legacy design: Reinforced paper gaskets can be a suitable option for less demanding static sealing requirements where they have proven effective.

By systematically matching the gasket, lip, and case materials to your operating conditions, you ensure the long-term reliability of the entire sealing system.

Summary Table:

| Gasket Material | Key Characteristics | Best For Applications |

|---|---|---|

| Fluoroelastomer (FKM) | Excellent high-temperature and chemical resistance | Aerospace, oil & gas, aggressive chemicals |

| Nitrile (NBR) | Cost-effective, reliable with oils and fuels | General-purpose industrial machinery |

| EPDM | Superior resistance to water, steam, and weather | Hydraulic systems, outdoor equipment |

| Reinforced Paper | Economical, traditional option | Less demanding or legacy designs |

Need a custom PTFE seal solution? The right gasket is just one part of the equation. At KINTEK, we engineer the entire seal system—PTFE lip, gasket, and metal case—to work in perfect harmony for your specific application in semiconductor, medical, laboratory, or industrial equipment.

We provide precision manufacturing and custom fabrication from prototypes to high-volume orders.

Contact our experts today for a solution that delivers unmatched reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech