To be direct, machined Polytetrafluoroethylene (PTFE) parts are critical components in a wide range of demanding industries. The most prominent users are aerospace, medical and pharmaceutical, electronics and semiconductor, chemical processing, and automotive sectors, where the material's unique properties solve problems that other plastics and metals cannot.

The core reason for PTFE's widespread adoption is its unparalleled combination of chemical inertness, high-temperature stability, and extremely low friction. Industries don't choose PTFE for its strength; they choose it for its ability to survive and perform in environments that would destroy most other materials.

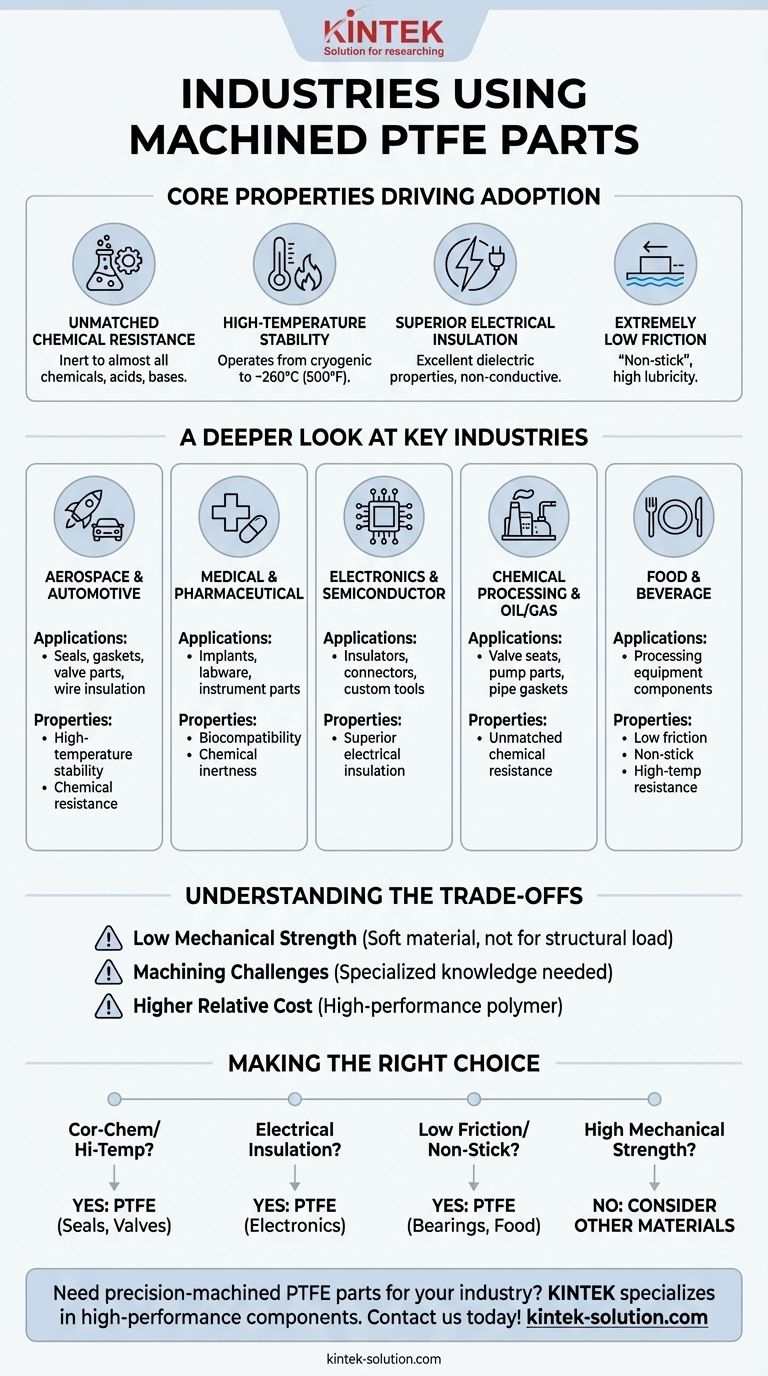

The Core Properties Driving PTFE Adoption

The value of machined PTFE parts is not based on a single characteristic, but on a powerful combination of properties. Understanding these attributes makes it clear why certain industries rely on it so heavily.

Unmatched Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals, acids, and bases. This makes it an essential material for any application involving corrosive substances.

This property is non-negotiable in the chemical processing, oil and gas, and pharmaceutical industries for components like valve seats, seals, and pump parts.

High-Temperature Stability

PTFE maintains its integrity over a wide temperature range, from cryogenic levels up to approximately 260°C (500°F).

This thermal resilience is critical for high-performance parts in the aerospace, automotive, and general industrial sectors, where components are exposed to extreme heat.

Superior Electrical Insulation

PTFE has excellent dielectric properties, meaning it does not conduct electricity. It is one of the best insulating materials known.

This makes it the material of choice for insulators, connectors, and enclosures in the electronics and semiconductor manufacturing industries.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This inherent lubricity is why it's known commercially as Teflon.

This "non-stick" quality is vital for food processing equipment and for mechanical parts like bearings, bushings, and wear pads that require smooth, low-effort movement.

A Deeper Look at Key Industries and Applications

Seeing how these properties translate into specific parts provides a clear picture of PTFE's role in modern engineering.

Aerospace & Automotive

In these industries, reliability under stress is paramount. PTFE is used for critical seals, gaskets, valve components, and wire insulation that must withstand extreme temperatures and aggressive fluids.

Medical & Pharmaceutical

Biocompatibility and purity are key. PTFE is used for medical implants, analytical instrument components, and custom labware like containers and funnels because it does not react with biological tissues or aggressive research chemicals.

Electronics & Semiconductor

The need for pristine electrical insulation drives PTFE's use here. It is machined into high-performance insulators, custom tools for semiconductor processing, and protective enclosures for sensitive components.

Chemical Processing & Oil/Gas

This is PTFE's home turf. Its chemical inertness makes it indispensable for valve bodies, seats, seals, pump parts, and pipe flange gaskets that are in constant contact with highly corrosive materials.

Food & Beverage

The combination of non-stick properties and high-temperature resistance makes PTFE ideal for components in food processing and packaging equipment, ensuring clean operation and easy maintenance.

Understanding the Trade-offs

No material is perfect, and relying on PTFE requires acknowledging its limitations. Being an effective advisor means presenting a complete picture.

Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for structural applications and can deform or "creep" under a sustained load, which must be accounted for in component design.

Machining Challenges

While it can be machined to precise tolerances, its softness and high thermal expansion rate require specialized knowledge and techniques. Holding very tight dimensions can be more difficult than with metals or harder plastics.

Higher Relative Cost

PTFE is a high-performance polymer, and its cost reflects that. It is chosen for applications where its unique survival capabilities justify the investment, not for general-purpose use.

Making the Right Choice for Your Application

Selecting the right material begins with defining your primary engineering challenge.

- If your primary focus is survival in corrosive chemical or high-temperature environments: PTFE is an industry-standard choice for seals, valves, and fluid-handling components.

- If your primary focus is electrical insulation for sensitive electronics: PTFE's exceptional dielectric properties make it a top-tier candidate.

- If your primary focus is creating a low-friction or non-stick surface: PTFE is the ideal material for bearings, wear pads, and food-grade equipment.

- If your primary focus is high mechanical strength or structural load-bearing: You should consider other materials, as pure PTFE will likely fail in this role.

Ultimately, PTFE is the material of choice when performance and reliability in extreme conditions are non-negotiable.

Summary Table:

| Industry | Key PTFE Properties Utilized | Common Applications |

|---|---|---|

| Aerospace & Automotive | High-temperature stability, Chemical resistance | Seals, gaskets, valve components, wire insulation |

| Medical & Pharmaceutical | Biocompatibility, Chemical inertness | Medical implants, labware, analytical instrument parts |

| Electronics & Semiconductor | Superior electrical insulation | Insulators, connectors, custom semiconductor tools |

| Chemical Processing & Oil/Gas | Unmatched chemical resistance | Valve seats, pump parts, pipe flange gaskets |

| Food & Beverage | Low friction, Non-stick, High-temperature resistance | Food processing equipment components |

Need precision-machined PTFE parts for your industry?

KINTEK specializes in manufacturing high-performance PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet the demanding requirements of extreme environments.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application