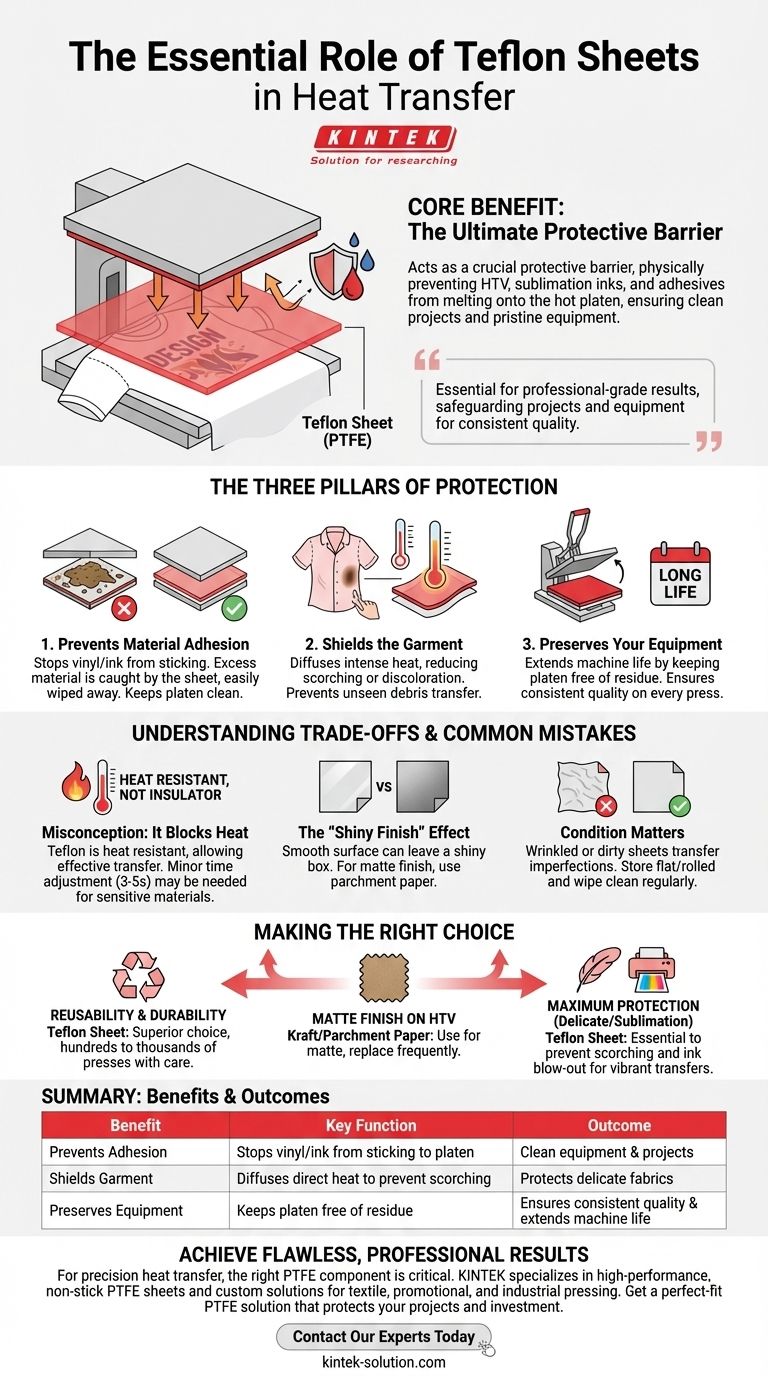

At its core, the non-stick surface of a Teflon sheet acts as a crucial protective barrier during heat transfer applications. It physically prevents materials like heat transfer vinyl (HTV), sublimation inks, and adhesives from melting onto the hot upper platen of your heat press, ensuring your project remains clean and your equipment stays pristine.

The benefit of Teflon's non-stick surface goes beyond simple convenience. It is an essential component for achieving professional-grade results by safeguarding both the project and the equipment from damage, ensuring consistency and quality with every press.

The Three Pillars of Protection

A Teflon sheet is more than just a non-stick layer; it serves three distinct protective functions that are critical for successful heat transfer work. Understanding each role clarifies why it is considered an indispensable tool.

1. Preventing Material Adhesion

This is the most direct benefit of its non-stick property. When heated, vinyl and inks can sometimes ooze or sublimate beyond the edges of their carrier or paper.

Without a barrier, this excess material will permanently bond to the hot metal platen of your press. The Teflon sheet catches this residue, which can be wiped away effortlessly once cooled.

2. Shielding the Garment

The sheet also protects the item you are pressing. It diffuses the direct, intense heat, reducing the risk of scorching or discoloring the fabric, which is especially important for delicate materials like polyester blends.

Furthermore, it prevents any unseen debris on the heat platen from being transferred and pressed permanently into your garment.

3. Preserving Your Equipment

A clean heat platen is non-negotiable for quality work. Any residue left from a previous job—be it a fleck of vinyl or a smudge of ink—will be heated and pressed into every subsequent project, ruining them.

Using a Teflon sheet with every press is the simplest way to keep your platen in perfect condition, extending the life of your equipment and guaranteeing a clean transfer every time.

Understanding the Trade-offs and Common Mistakes

While highly effective, using a Teflon sheet is not without nuances. Being aware of them allows you to adapt your process for perfect results.

Misconception: It Blocks Heat

A Teflon sheet is heat resistant, not a heat insulator. It is specifically designed to allow heat to transfer through it effectively.

However, any layer between the heat source and the design can have a minor effect. For most standard projects, no adjustment is needed. For highly sensitive materials, a small increase in time (3-5 seconds) may be required to compensate.

The "Shiny Finish" Effect

The perfectly smooth surface of a Teflon sheet can sometimes leave a shiny box or imprint on certain types of heat transfer vinyl. This can be a desirable aesthetic, but if you require a matte finish, using a sheet of parchment paper is a common alternative.

Condition Matters

A wrinkled, creased, or dirty Teflon sheet will transfer those imperfections to your project. Always store your sheet flat or loosely rolled and wipe it down regularly to ensure it is free of any dust, ink, or vinyl residue.

Making the Right Choice for Your Project

Choosing the right protective layer is a key decision that influences the final look and feel of your work.

- If your primary focus is reusability and long-term durability: A Teflon sheet is the superior choice, as it can be used for hundreds or even thousands of presses with proper care.

- If your primary focus is achieving a matte finish on HTV: Use a sheet of kraft or parchment paper, but be prepared to replace it more frequently.

- If your primary focus is maximum protection for delicate fabrics or sublimation: A Teflon sheet is essential to prevent scorching and ink blow-out, ensuring a vibrant and flawless transfer.

Ultimately, integrating a protective sheet into your workflow is a foundational step in elevating your projects from hobbyist attempts to professional-quality products.

Summary Table:

| Benefit | Key Function | Outcome |

|---|---|---|

| Prevents Adhesion | Stops vinyl/ink from sticking to the heat platen | Clean equipment & projects |

| Shields Garment | Diffuses direct heat to prevent scorching | Protects delicate fabrics |

| Preserves Equipment | Keeps platen free of residue | Ensures consistent quality & extends machine life |

Achieve flawless, professional results on every press. For heat transfer projects requiring precision and reliability, the right PTFE component is critical. KINTEK specializes in manufacturing high-performance, non-stick PTFE sheets and custom components for the textile, promotional product, and industrial heat pressing industries. Our sheets are engineered for exceptional heat transfer, durability, and reusability.

Whether you need a standard size or a custom-fabricated solution for your specific equipment, KINTEK delivers. Contact our experts today to discuss your application and get a perfect-fit PTFE solution that protects your projects and your investment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications