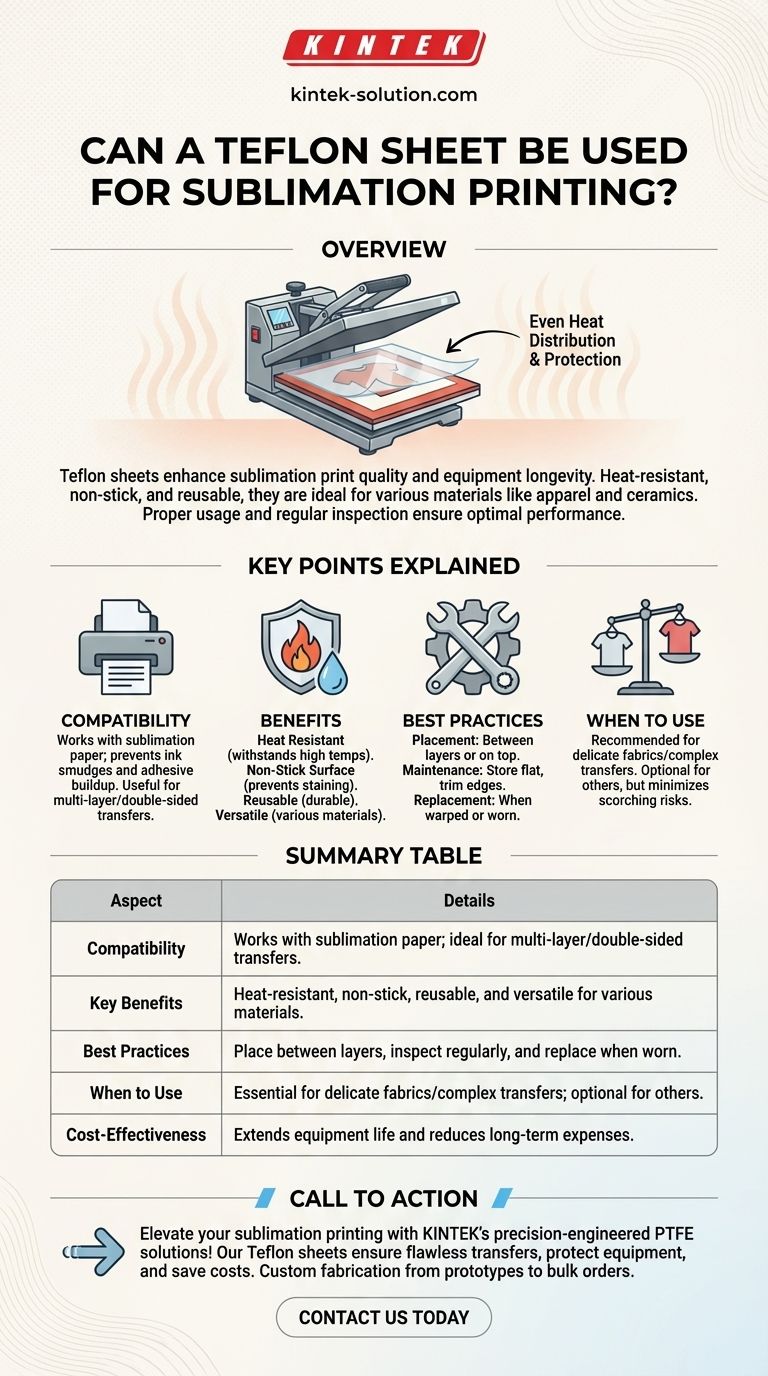

Teflon sheets can indeed be used for sublimation printing, offering benefits like even heat distribution, protection against staining, and reusability. While not strictly necessary, they enhance print quality and equipment longevity. These sheets are heat-resistant and non-stick, making them ideal for various materials, including apparel and ceramics. Proper usage involves placing the sheet between layers or on top of transfers, and regular inspection ensures optimal performance. Best practices include selecting the right size, testing on scrap material, and replacing worn-out sheets to maintain print quality.

Key Points Explained:

-

Compatibility with Sublimation Printing

- Teflon sheets work well with sublimation paper, ensuring even heat distribution and preventing ink smudges or adhesive buildup.

- They are particularly useful for multi-layer transfers or double-sided printing, where the sheet acts as a protective barrier.

-

Benefits of Using Teflon Sheets

- Heat Resistance: Withstands high temperatures, critical for sublimation processes.

- Non-Stick Surface: Prevents staining and ensures smooth transfers without residue.

- Reusability: Durable and can be reused multiple times, though regular inspection for wear (e.g., discoloration) is recommended.

- Versatility: Suitable for various materials, including apparel, ceramics, and paper.

-

Best Practices for Usage

- Placement: For vinyl transfers, cover existing layers; for double-sided prints, place the adhesive teflon sheet between both sides.

- Maintenance: Store flat or rolled, trim frayed edges, and test on scrap material before full-scale use.

- Replacement: Replace sheets when they show signs of warping or excessive wear to avoid uneven prints.

-

When to Use (or Skip) a Teflon Sheet

- Recommended: For delicate fabrics or complex transfers to ensure even heat and protection.

- Optional: Some fabrics may not require it, but using one minimizes risks like scorching.

-

Economic and Practical Considerations

- While an added cost, Teflon sheets extend the life of heat presses and materials, reducing long-term expenses.

- Their reusability makes them cost-effective for high-volume printing.

By integrating these practices, users can achieve consistent, high-quality sublimation results while safeguarding their equipment and materials.

Summary Table:

| Aspect | Details |

|---|---|

| Compatibility | Works with sublimation paper; ideal for multi-layer/double-sided transfers. |

| Key Benefits | Heat-resistant, non-stick, reusable, and versatile for various materials. |

| Best Practices | Place between layers, inspect regularly, and replace when worn. |

| When to Use | Essential for delicate fabrics/complex transfers; optional for others. |

| Cost-Effectiveness | Extends equipment life and reduces long-term expenses. |

Elevate your sublimation printing with KINTEK’s precision-engineered PTFE solutions! Our Teflon sheets ensure flawless transfers, protect your equipment, and save costs through durability. Whether you’re in apparel, ceramics, or industrial printing, we offer custom fabrication from prototypes to bulk orders. Contact us today to find the perfect solution for your needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What material properties make polymer-plastic ball bearings suitable for diverse industries? Solve Harsh Environment Challenges

- What are some unique features of expanded PTFE gaskets? Superior Conformability & Creep Resistance

- What makes PTFE suitable for lining butterfly valves? Unlock Superior Corrosion Resistance and Purity

- Where are PTFE energized seals used in oil and gas operations? Essential Sealing Solutions for Harsh Environments

- What industries commonly use PTFE butterfly valves and why? For Superior Chemical Resistance & Purity

- What types of projects are Teflon sheets compatible with? From Crafts to Industry

- How do PTFE seals compare to traditional sealing materials in terms of service life? Extend Equipment Lifespan Dramatically

- How does the built-in spring compensate for wear in PTFE shaft seals? Ensure Long-Term Sealing Reliability