Yes, absolutely. PTFE encapsulated O-rings are specifically designed to meet and exceed a wide range of stringent industry standards. Their unique construction allows them to comply with critical regulations for purity, safety, and performance, including FDA, USP Class VI, and various international dimensional standards.

The core takeaway is that while standard elastomers provide the mechanical seal, the chemically inert PTFE encapsulation is what enables compliance with the demanding purity and non-reactivity requirements of industries like medical, food processing, and semiconductor manufacturing.

Why PTFE Encapsulation is Critical for Compliance

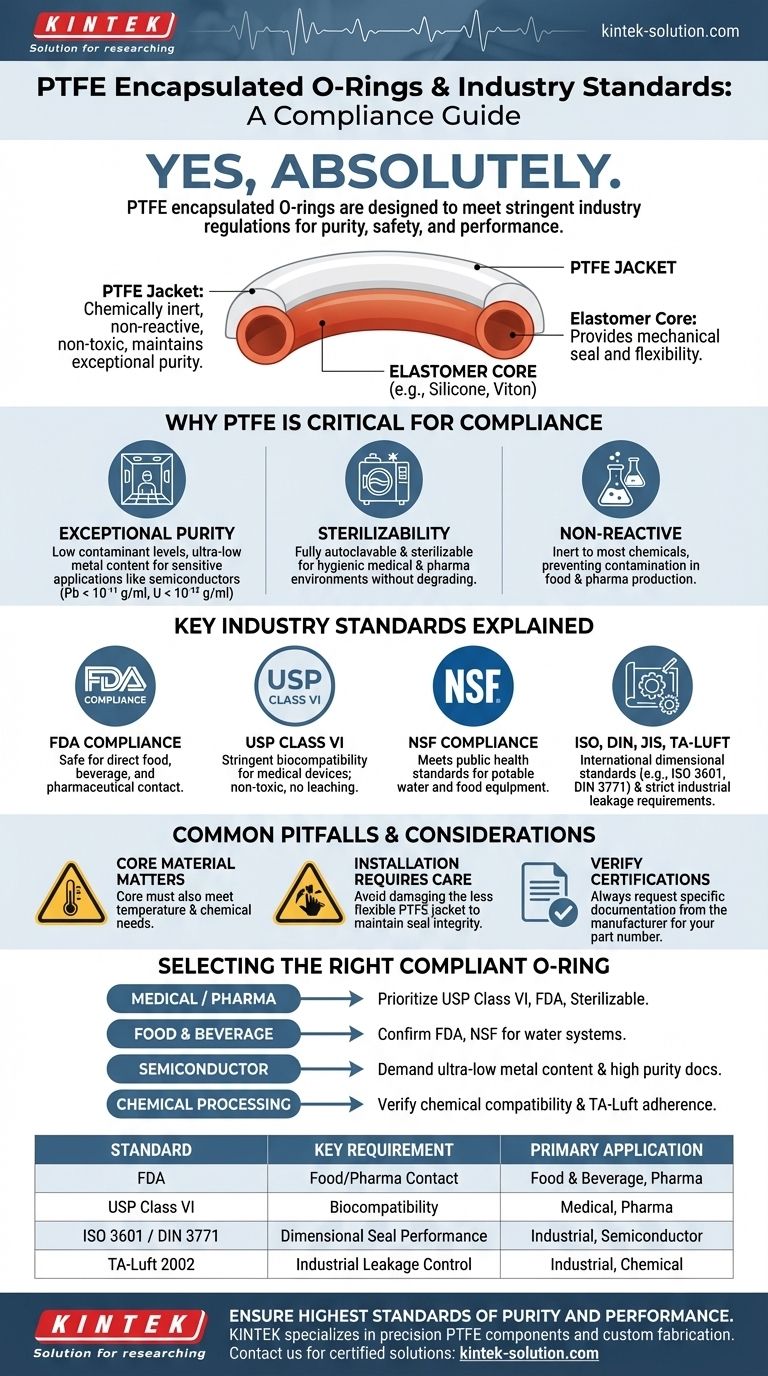

The compliance of these O-rings stems from their composite design: a flexible elastomer core (like Silicone or Viton) is seamlessly enclosed in a durable Polytetrafluoroethylene (PTFE) jacket. This structure combines the best of both materials.

The Role of the PTFE Jacket

The outer PTFE shell is the key to its broad compliance. This material is almost universally inert, meaning it does not react with the chemicals or products it contacts.

This non-reactive and non-toxic property is essential for regulated industries like pharmaceuticals and food production, where contamination is not an option.

Exceptional Purity and Cleanliness

PTFE encapsulated O-rings can be manufactured to maintain extremely low levels of contaminants.

For sensitive applications like semiconductor fabrication, they can feature lead content below 10⁻¹¹ g/ml and uranium below 10⁻¹² g/ml, preventing process contamination.

Sterilizability for Sensitive Applications

A critical requirement in the medical and pharmaceutical fields is the ability to sterilize components. These O-rings are fully sterilizable and autoclavable, ensuring they can be used safely in hygienic environments without degrading.

Key Industry Standards Explained

PTFE encapsulated O-rings adhere to a portfolio of standards that certify their material safety, biocompatibility, and physical performance.

FDA Compliance (Food and Drug Administration)

FDA compliance confirms that the materials are safe for direct contact with food, beverages, and pharmaceuticals. This is based on the regulations set forth in the Federal Food, Drug, and Cosmetic Act.

USP Class VI (United States Pharmacopeia)

This is one of the most stringent tests for biocompatibility of plastics used in medical devices. USP Class VI compliance ensures the material is non-toxic and will not leach harmful substances when in contact with the human body.

NSF Compliance (National Sanitation Foundation)

For applications involving drinking water or food service equipment, NSF compliance is often available. This certifies that the product meets public health and safety standards.

Dimensional and Performance Standards

Beyond material safety, these O-rings conform to international standards for physical dimensions, such as ISO 3601, BS1806, DIN 3771, and JIS B2401. This ensures interchangeability and reliable sealing performance.

For industrial applications, they can also meet strict leakage requirements, such as TA-Luft 2002 [VDI 2440/2200].

Common Pitfalls and Considerations

While highly compliant, successful implementation requires understanding their specific characteristics. Not all encapsulated O-rings are created equal, and proper selection is crucial.

The Core Material Still Matters

The compliance of the entire O-ring depends on both the PTFE jacket and the inner elastomer. You must ensure the chosen core material (e.g., Silicone, FKM/Viton) also meets the temperature and chemical requirements of your system.

Installation Requires Care

The PTFE jacket is robust but less flexible than a standard rubber O-ring. Care must be taken during installation to avoid scratching or damaging the jacket, which could compromise the seal's integrity and its compliance.

Always Verify Manufacturer Certifications

"Compliance is available" does not mean every product automatically carries every certification. Always request documentation from the manufacturer to verify that the specific part number you are purchasing meets the exact standards your application requires.

Selecting the Right Compliant O-Ring for Your Application

Choosing the correct O-ring requires matching its certifications to your specific industry and operational needs.

- If your primary focus is medical or pharmaceutical: Prioritize USP Class VI and FDA compliance, and ensure the seal is documented as sterilizable or autoclavable.

- If your primary focus is food and beverage: Confirm FDA compliance and, for any potable water systems, look for specific NSF certifications.

- If your primary focus is semiconductor manufacturing: Demand documentation proving ultra-low metal content and high chemical purity to prevent process contamination.

- If your primary focus is aggressive chemical processing: Verify broad chemical compatibility and adherence to industrial leakage standards like TA-Luft.

By verifying the specific certifications for your intended use, you can confidently deploy these advanced seals in your most critical environments.

Summary Table:

| Standard | Key Requirement | Primary Industry Application |

|---|---|---|

| FDA Compliance | Safe for direct contact with food, beverages, and pharmaceuticals | Food & Beverage, Pharmaceutical |

| USP Class VI | Stringent biocompatibility testing for medical devices | Medical, Pharmaceutical |

| ISO 3601 / DIN 3771 | Dimensional standards for reliable sealing performance | Industrial, Semiconductor |

| TA-Luft 2002 | Strict leakage requirements for industrial emissions control | Industrial, Chemical Processing |

Ensure your application meets the highest standards of purity and performance. KINTEK specializes in manufacturing precision PTFE components, including compliant encapsulated O-rings, seals, liners, and labware. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your semiconductor, medical, laboratory, or industrial equipment operates reliably under stringent regulations.

Contact us today to discuss your specific requirements and receive certified components tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability