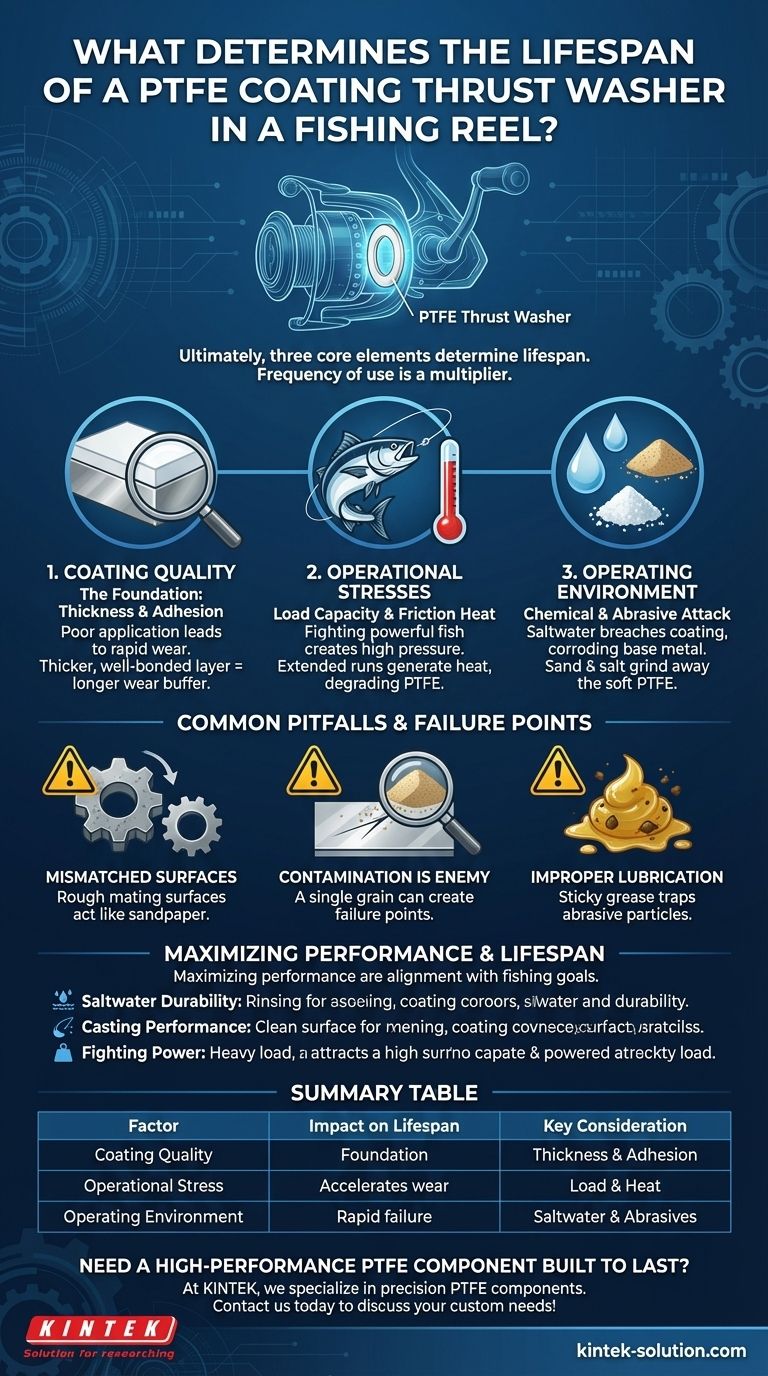

Ultimately, three core elements determine the lifespan of a PTFE-coated thrust washer in a fishing reel: the intrinsic quality of the coating, the mechanical stresses it endures during operation, and the environment it's exposed to. The frequency of use acts as a multiplier, accelerating the effects of these factors.

The key takeaway is that a PTFE thrust washer does not wear out in a vacuum. Its lifespan is a direct result of its interaction with the entire reel system—from the surfaces it touches to the grit and saltwater it encounters.

What is a PTFE Thrust Washer and Why Does it Matter?

The Role of a Simple Component

A thrust washer is designed to handle axial loads, which in a reel, often occurs between the spool and the main gear assembly. It's a critical friction point.

By coating this washer with PTFE (Polytetrafluoroethylene), manufacturers leverage the material's extremely low coefficient of friction.

The Performance Benefits

This PTFE coating is what translates into tangible performance gains. It provides a protective, self-lubricating layer that reduces friction for a smoother drag system and more efficient operation.

This leads to increased durability, better corrosion resistance (especially for saltwater use), and can even contribute to improved casting distance by minimizing parasitic friction on the spool shaft.

The Core Factors That Dictate Lifespan

Factor 1: The Quality of the Coating Itself

The foundation of the washer's longevity is the manufacturing process. The thickness and adhesion of the PTFE layer are paramount.

A thin, poorly applied coating will wear through quickly, exposing the base metal and negating all performance benefits. A thicker, well-bonded coating provides a much larger wear buffer.

Factor 2: Operational Stresses

The primary stress is load capacity. Fighting large, powerful fish places immense pressure on the drag system and, by extension, the thrust washer. Consistently high loads will accelerate wear.

The secondary stress is heat generated by friction. During a long, fast run, the friction between the washer and its mating surfaces creates heat, which can degrade the PTFE over time.

Factor 3: The Operating Environment

Chemical exposure is a major factor, particularly saltwater. While PTFE itself is highly inert, any microscopic breach in the coating allows salt to attack the base metal of the washer, causing it to fail from underneath.

Contaminants like sand, dust, and dried salt crystals act as an abrasive, literally grinding away the soft PTFE coating far faster than normal use would.

Common Pitfalls and Failure Points

Mismatched Mating Surfaces

The surface the thrust washer rubs against is just as important as the washer itself. A rough, scored, or corroded mating surface will act like sandpaper, rapidly destroying the PTFE coating.

For optimal life, the PTFE washer should operate against a smooth, polished, and hard surface.

Contamination is the True Enemy

The single fastest way to destroy a PTFE thrust washer is to allow contaminants into the mechanism. A single grain of sand can score the coating, creating a weak point for future failure.

Proper sealing and regular, careful cleaning are non-negotiable for extending the life of this component.

Improper Lubrication

While PTFE is considered "self-lubricating," the application is critical. Using a heavy, sticky grease can actually be detrimental, as it attracts and holds abrasive particles like sand and dirt.

Many high-performance applications use a very light oil or a specialized dry lubricant to avoid this contamination trap.

Maximizing Performance and Lifespan

To get the most out of your component, you must align your maintenance and selection with your primary fishing goal.

- If your primary focus is saltwater durability: Prioritize washers with excellent coating adhesion and commit to a strict freshwater rinse and cleaning regimen after every outing.

- If your primary focus is casting performance: Ensure the washer and its mating surfaces are impeccably clean and consider using a dry lube to minimize friction without attracting dirt.

- If your primary focus is fighting powerful fish: Select a washer specifically rated for high loads and ensure the rest of your drag system is maintained to distribute heat and pressure effectively.

Ultimately, treating the thrust washer as a critical, high-performance component of a larger system is the key to its longevity.

Summary Table:

| Factor | Impact on Lifespan | Key Consideration |

|---|---|---|

| Coating Quality | Foundation of longevity | Thickness and adhesion of the PTFE layer |

| Operational Stress | Accelerates wear | Load capacity and heat from friction |

| Operating Environment | Can cause rapid failure | Exposure to saltwater, sand, and other abrasives |

Need a high-performance PTFE component built to last? The lifespan of your critical components depends on the quality of the coating and its resistance to stress and harsh environments. At KINTEK, we specialize in manufacturing precision PTFE components like seals, liners, and labware for demanding industries, including specialized applications. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to ensure your components meet exact specifications for durability and performance.

Contact us today to discuss your custom PTFE needs and enhance your product's reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability