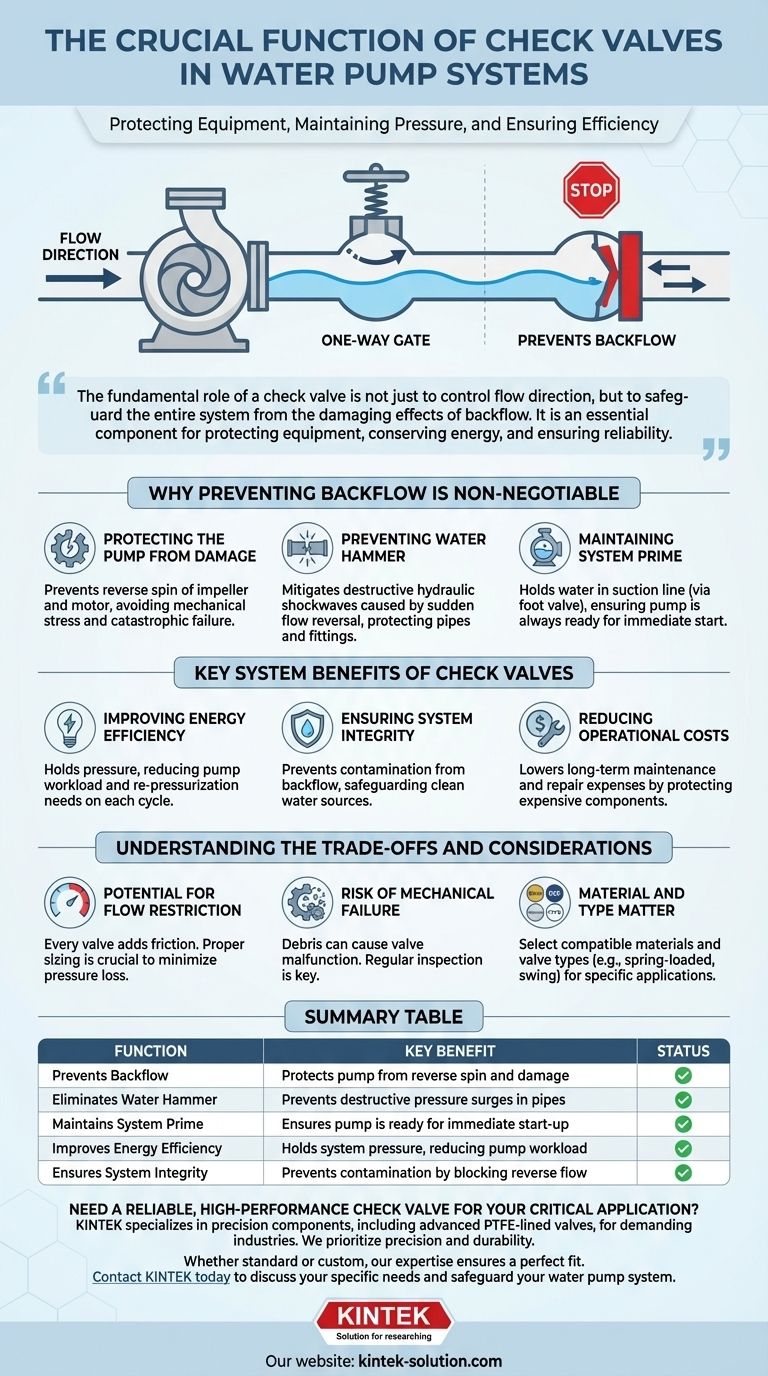

At its core, a check valve in a water pump system acts as a one-way gate. Its primary function is to permit water to flow in only one direction—away from the pump—and to automatically prevent any backflow when the pump shuts off. This simple mechanism is critical for protecting the pump, maintaining system pressure, and ensuring the operational efficiency of the entire system.

The fundamental role of a check valve is not just to control flow direction, but to safeguard the entire system from the damaging effects of backflow. It is an essential component for protecting equipment, conserving energy, and ensuring reliability.

Why Preventing Backflow is Non-Negotiable

Understanding the consequences of backflow reveals why check valves are so critical. The reverse flow of water in a piping system is not a harmless event; it can cause catastrophic failure and significant inefficiency.

Protecting the Pump from Damage

When a pump shuts down, the column of water in the discharge pipe is subject to gravity and will attempt to flow back toward the pump.

This reverse flow can cause the pump's impeller and motor to spin backward at high speeds. If the pump restarts during this reverse spin, the resulting mechanical stress can be immense, potentially causing a bent shaft, damaged motor, or catastrophic pump failure.

Preventing Water Hammer

Water hammer is a destructive hydraulic shockwave created when a moving fluid is forced to stop or change direction suddenly.

Without a check valve, a column of water rushing back down a pipe can slam to a halt, creating a pressure surge that can rupture pipes, break fittings, and destroy gauges. A check valve closes to prevent this violent reversal.

Maintaining System Prime

Many types of pumps, particularly centrifugal and jet pumps, cannot pump air. They must be "primed," meaning the pump casing and suction line must be full of water to operate.

A check valve (often a specialized type called a foot valve) installed on the suction line holds water in the system when the pump is off. This ensures the pump remains primed and is ready to start immediately without manual intervention.

Key System Benefits of Check Valves

Beyond preventing catastrophic failure, check valves contribute directly to the system's overall health and efficiency.

Improving Energy Efficiency

By holding pressure in the lines after the pump stops, a check valve prevents the system from having to re-pressurize the entire pipe network from zero on every cycle. This significantly reduces the pump's workload and energy consumption, especially in systems that cycle on and off frequently.

Ensuring System Integrity

Check valves are crucial for preventing contamination. In applications like well water systems, a check valve ensures that potentially unsanitary water from the surface plumbing cannot drain back down and contaminate the clean water source.

Reducing Operational Costs

By protecting the pump from damage, preventing pipe ruptures, and saving energy, a check valve directly lowers the long-term operational and maintenance costs of a water system. Its initial cost is a small investment to protect much more expensive components.

Understanding the Trade-offs and Considerations

While essential, a check valve is not a "fit and forget" component. Proper selection and awareness of its limitations are key to its function.

Potential for Flow Restriction

Every valve introduces some level of friction and pressure loss (known as head loss) into a system. A poorly sized or improperly designed check valve can create significant resistance, forcing the pump to work harder and reducing overall efficiency.

Risk of Mechanical Failure

Check valves are mechanical devices that can fail. Debris in the water can lodge in the valve, preventing it from closing fully (negating its purpose) or causing it to jam shut (blocking all flow). Regular inspection, especially in systems with sediment, is important.

Material and Type Matter

The material of the check valve—such as brass, stainless steel, PVC, or advanced options like PTFE-lined valves—must be compatible with the fluid to prevent corrosion. The specific type (e.g., spring-loaded, swing check) also impacts performance, such as the closing speed and degree of flow restriction.

Making the Right Choice for Your System

The application of a check valve depends entirely on your system's design and your primary goal.

- If your primary focus is protecting a submersible well pump: A check valve is essential to prevent backspin and water hammer, protecting your significant investment.

- If your primary focus is maintaining the prime on a surface pump: A foot valve (a check valve with an integrated strainer) at the end of the suction line is non-negotiable for reliable operation.

- If your primary focus is maximizing energy efficiency in a booster system: Ensure your check valve is correctly sized for minimal pressure loss and is placed strategically to reduce pump cycling.

Ultimately, a well-chosen and properly installed check valve is a small component that delivers immense protection and efficiency to your entire water system.

Summary Table:

| Function | Key Benefit |

|---|---|

| Prevents Backflow | Protects pump from reverse spin and damage |

| Eliminates Water Hammer | Prevents destructive pressure surges in pipes |

| Maintains System Prime | Ensures pump is ready for immediate start-up |

| Improves Energy Efficiency | Holds system pressure, reducing pump workload |

| Ensures System Integrity | Prevents contamination by blocking reverse flow |

Need a reliable, high-performance check valve for your critical application?

KINTEK specializes in manufacturing precision components, including advanced PTFE-lined valves, for demanding industries like semiconductor, medical, and laboratory systems. We prioritize precision and durability to ensure your equipment is protected from backflow and operates at peak efficiency.

Whether you need a standard component or a custom-fabricated solution from prototype to high-volume orders, our expertise ensures a perfect fit for your system's requirements.

Contact KINTEK today to discuss your specific needs and safeguard your water pump system with a valve you can trust.

Visual Guide

Related Products

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- What are the characteristics of wide mouth PTFE laboratory bottles? Engineered for Extreme Chemical & Thermal Resistance

- Why is PTFE suitable for electrical applications? Discover Its Superior Insulating Properties

- Why is PTFE considered cost-effective for plumbing applications? Maximize Long-Term Value & Reliability

- What are the main advantages of PTFE as a material for laboratory bottles? Superior Chemical & Thermal Resistance

- What does PTFE stand for? The Science Behind the Super-Material