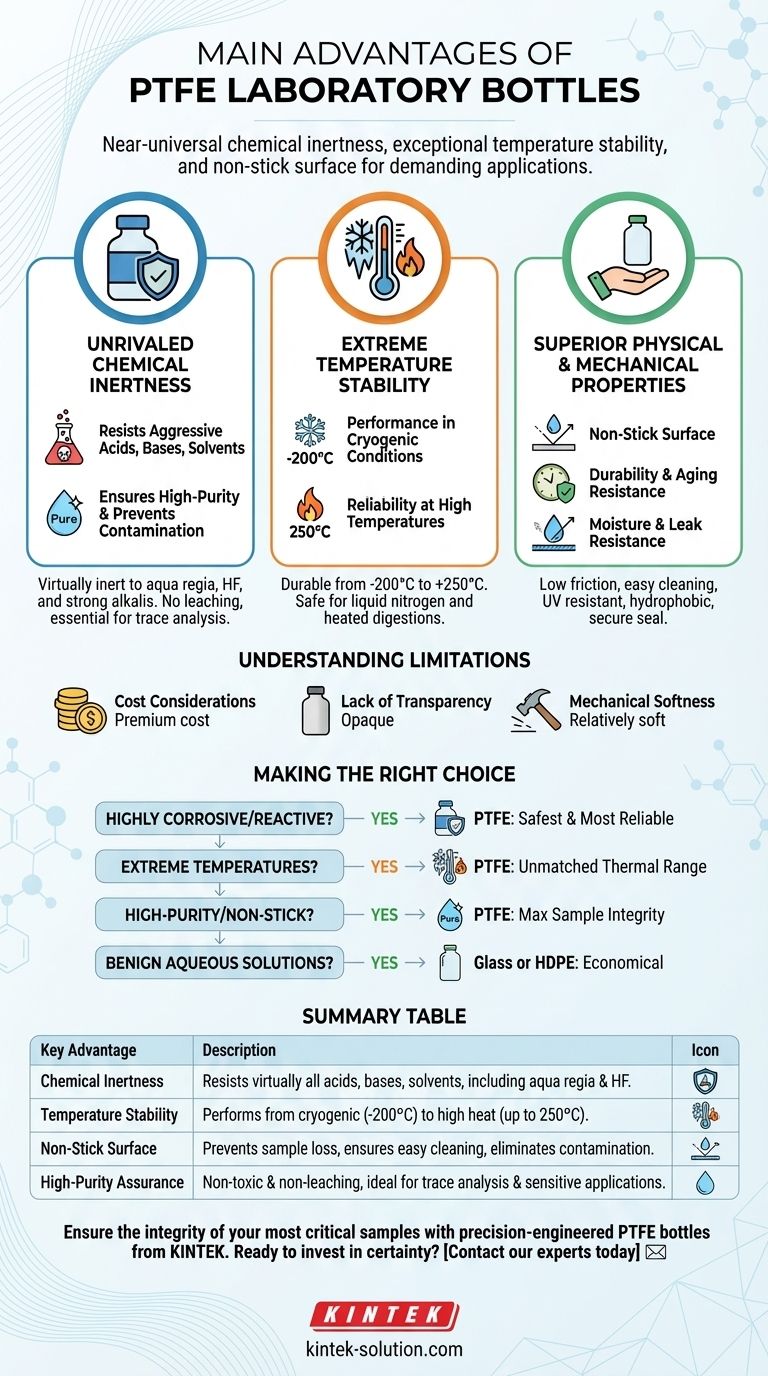

The primary advantages of PTFE for laboratory bottles are its near-universal chemical inertness, its exceptional stability across a wide range of extreme temperatures, and its non-stick surface that prevents sample contamination. These properties make it the material of choice for storing highly corrosive reagents, performing high-purity analysis, and working in cryogenic or high-heat conditions where glass or other plastics would fail.

PTFE is not just another plastic; it is an engineering solution for the most demanding laboratory applications. Its value lies in providing an inert and stable environment, ensuring that the integrity of the sample and the reliability of the experiment are never compromised by the container itself.

The Unrivaled Chemical Inertness of PTFE

The most critical advantage of PTFE is its remarkable resistance to chemical attack. This property is fundamental to protecting both the sample within the bottle and the experiment's validity.

Resisting Aggressive Acids, Bases, and Solvents

PTFE is virtually inert to almost all chemicals, including highly corrosive substances like aqua regia, hydrofluoric acid, strong alkalis, and aggressive organic solvents. This makes it an essential tool for storing and handling reagents that would degrade or destroy other materials.

Ensuring High-Purity and Preventing Contamination

Because PTFE is chemically inert and non-toxic, it does not leach impurities into the stored solution. This is critical for trace-element analysis, pharmaceutical research, and any high-purity work where even minute contamination could invalidate results.

Extreme Temperature Stability

PTFE maintains its structural integrity and chemical properties across an exceptionally broad temperature range, outperforming nearly all other common laboratory polymers.

Performance in Cryogenic Conditions

PTFE bottles are suitable for ultra-low temperature applications, remaining durable and resistant to becoming brittle at temperatures approaching -200°C (-328°F). This allows for the safe storage of samples in liquid nitrogen or other cryogenic environments.

Reliability at High Temperatures

On the other end of the spectrum, PTFE can be used continuously at high temperatures, typically up to 250°C (482°F). This makes it ideal for applications involving sample digestion or dissolution with heated, corrosive agents.

Superior Physical and Mechanical Properties

Beyond its chemical and thermal resistance, PTFE offers physical characteristics that enhance its utility and reliability in a laboratory setting.

The Advantage of a Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid, giving it a uniquely non-stick surface. This property minimizes sample loss during transfer and makes the bottles exceptionally easy to clean and sterilize, preventing cross-contamination between experiments.

Durability and Aging Resistance

PTFE is highly resistant to aging and degradation from UV light or environmental exposure. This ensures a long service life, making the bottles a reliable, long-term investment. Its heavy-wall construction also provides mechanical strength and durability.

Moisture and Leak Resistance

The material is inherently hydrophobic, meaning it repels water and resists moisture absorption. When combined with a well-designed screw cap, PTFE bottles provide a secure, leak-free seal that protects sensitive contents from atmospheric moisture.

Understanding the Trade-offs and Limitations

While PTFE offers unparalleled performance in many areas, it's important to be aware of its specific limitations to make an informed decision.

Cost Considerations

PTFE is a premium performance polymer, and its cost is significantly higher than that of standard laboratory containers like glass, polypropylene (PP), or high-density polyethylene (HDPE). Its use is typically justified by the critical nature of the application.

Lack of Transparency

PTFE is opaque, meaning you cannot visually inspect the contents of the bottle without opening it. This can be a drawback for applications where monitoring volume or observing reactions is necessary.

Mechanical Softness

While durable, PTFE is a relatively soft material compared to glass. It can be scratched or abraded by hard or sharp implements, which could potentially compromise the smooth internal surface over time.

Making the Right Choice for Your Application

Selecting the right bottle material depends entirely on the specific demands of your work.

- If your primary focus is storing highly corrosive or reactive chemicals: PTFE is the safest and most reliable choice due to its near-universal chemical inertness.

- If your primary focus is working with extreme temperatures (cryogenic or high-heat): PTFE's wide thermal operating range is unmatched by nearly any other polymer.

- If your primary focus is high-purity analysis and avoiding sample contamination: PTFE's non-leaching and non-stick properties ensure maximum sample integrity and recovery.

- If your primary focus is general storage of benign aqueous solutions at room temperature: A more economical material like glass or HDPE may be sufficient for your needs.

Ultimately, choosing PTFE is an investment in certainty for your most critical and demanding applications.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents, including aqua regia and HF. |

| Temperature Stability | Performs from cryogenic (-200°C) to high heat (up to 250°C). |

| Non-Stick Surface | Prevents sample loss, ensures easy cleaning, and eliminates contamination. |

| High-Purity Assurance | Non-toxic and non-leaching, ideal for trace analysis and sensitive applications. |

Ensure the integrity of your most critical samples with precision-engineered PTFE bottles from KINTEK.

For semiconductor, medical, laboratory, and industrial professionals, the right container is not just a vessel—it's a guarantee of accuracy and safety. KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and custom labware. We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact solution for your demanding applications.

Ready to invest in certainty? Contact our experts today to discuss your specific needs and discover how our PTFE solutions can enhance your lab's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What role does thermal stability play in the use of Teflon membranes? Ensuring Reliable Performance in High-Heat Lab Applications

- How should PTFE shovels be cleaned and stored? Protect Your Investment with Proper Care

- What makes Teflon membranes versatile for use in various laboratory environments? Unmatched Chemical & Thermal Stability

- What are PTFE silicone septas and their role in the pharmaceutical industry? Ensure Sample Integrity and Accurate Analysis

- What specifications do PTFE filters meet for polychlorobenzenes? Ensure Compliance with NIOSH Method 5517

- What are PTFE lined caps made of? A Guide to Their Inert, Protective Construction

- What are the medical and laboratory equipment uses of PTFE? Unlock Biocompatibility and Chemical Resistance

- How does PTFE ensure seal integrity in chromatography vials? Achieve Leak-Free, Contaminant-Free Results