PTFE is an exceptional material for electrical applications due to its unique combination of properties, including extremely high dielectric strength, high electrical resistance, and a very low dielectric constant. This molecular-level stability prevents the flow of electricity, making PTFE one of the most reliable and widely used electrical insulators, especially in demanding environments.

The core reason for PTFE's electrical suitability lies in its stable and symmetric molecular structure. This structure creates a material that does not easily conduct or store electrical energy, but it's critical to understand that these properties can vary significantly based on the specific grade and manufacturing process of the PTFE component.

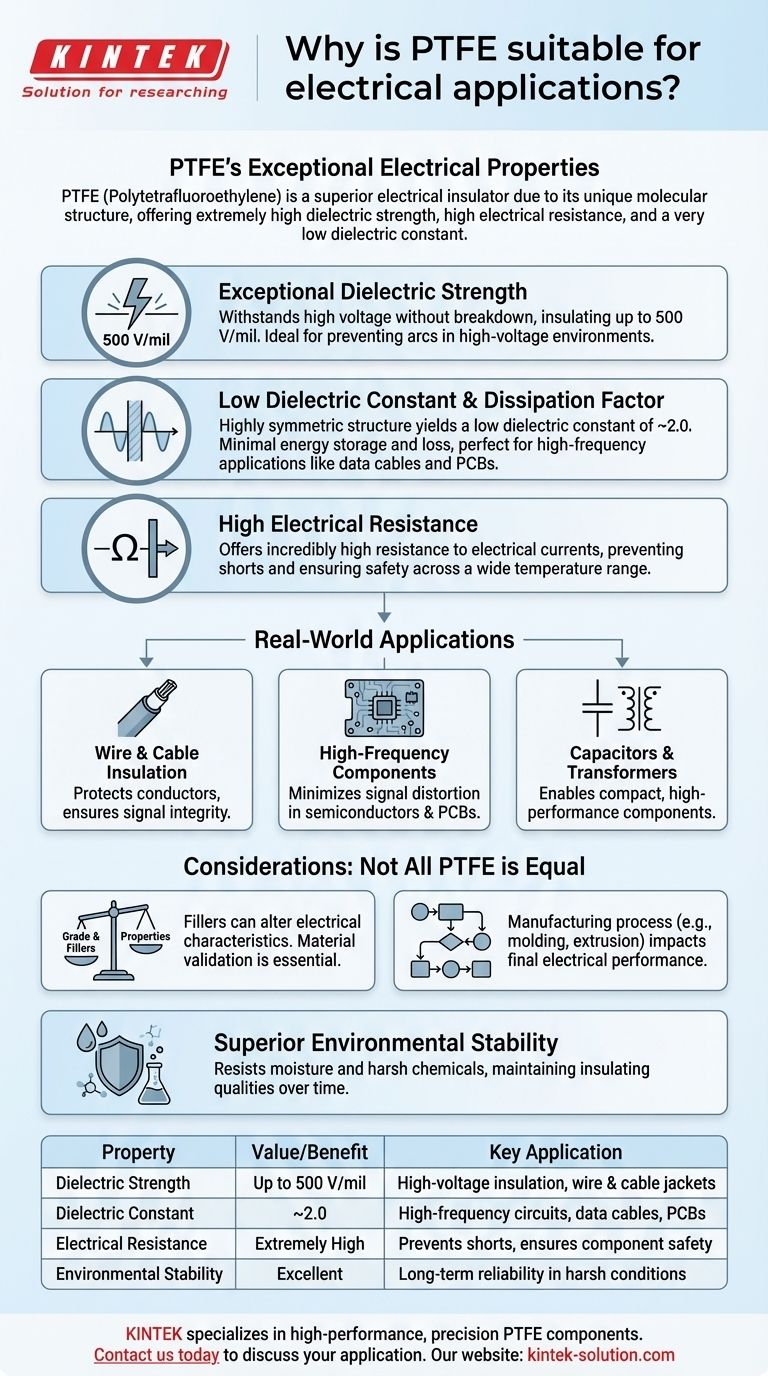

The Core Electrical Properties of PTFE

To understand why PTFE is a superior insulator, we need to examine its three primary electrical characteristics. These properties work in concert to ensure reliable and safe performance in electronic components.

Exceptional Dielectric Strength

Dielectric strength is a material's ability to withstand high voltage without breaking down and allowing current to pass through.

PTFE exhibits an extremely high dielectric strength, capable of insulating up to 500 volts per mil in thin sections. This makes it ideal for preventing arcs and voltage breakdowns in high-voltage environments.

This property is why PTFE is frequently used for wire insulation, high-voltage encapsulation devices, and standoff insulators that physically separate electrical components.

Low Dielectric Constant & Dissipation Factor

The dielectric constant measures how much electrical energy a material can store when subjected to an electric field.

PTFE's highly symmetric molecular structure gives it a very low dielectric constant of around 2.0. This means it stores very little energy, making it perfect for high-frequency applications like data cables and circuit boards where signal integrity is paramount.

A low dissipation factor means minimal energy is lost as heat, further enhancing its efficiency in high-frequency circuits.

High Electrical Resistance

Electrical resistance (or resistivity) is the fundamental measure of how strongly a material opposes the flow of electric current.

PTFE is one of the best insulating materials known, offering incredibly high resistance to electrical currents. This ensures that electricity stays within its intended path, preventing shorts and ensuring component safety.

Its performance remains consistent across a wide range of temperatures and frequencies, a key advantage over materials like PVC or nylon.

How These Properties Translate to Real-World Applications

The theoretical properties of PTFE directly enable its use in some of the most critical electrical and electronic components.

Wire and Cable Insulation

PTFE is commonly used as a wire wrap or extruded as a jacket for high-performance cables. Its combination of high dielectric strength and thermal stability protects the conductor and ensures signal integrity.

High-Frequency Components

In semiconductors and printed circuit boards (PCBs), PTFE's low dielectric constant is crucial. It minimizes signal distortion and power loss, enabling the reliable performance of modern high-speed electronics.

Capacitors and Transformers

PTFE film is used to separate conductive surfaces in capacitors. Its ability to insulate while being very thin allows for the construction of compact, high-performance components. It is also used in transformers where insulation must be reliable over a wide temperature range.

Understanding the Trade-offs and Considerations

While PTFE's base properties are excellent, an engineer must recognize that not all PTFE is created equal. The final performance of a component is deeply tied to its formulation and production.

The Impact of Grade and Fillers

The electrical properties of a PTFE component can be altered by the specific grade of the resin and the inclusion of any fillers.

While virgin PTFE offers the best insulating properties, adding fillers like carbon or glass can change its electrical characteristics. This makes material validation and testing essential.

The Importance of the Manufacturing Process

How a PTFE part is made—whether it's a molded sheet, an extruded tube, or a machined component—can yield different electrical performance results.

Close collaboration with a material supplier is necessary to ensure the manufacturing process aligns with the electrical requirements of the final application.

Superior Environmental Stability

A key advantage of PTFE is its resistance to moisture penetration. Unlike many other plastics, it maintains its excellent insulating qualities over time, even in humid or harsh chemical environments, ensuring long-term durability and reliability.

Making the Right Choice for Your Application

Selecting the right material requires matching the specific demands of your project to the tested properties of the PTFE grade you are considering.

- If your primary focus is high-voltage insulation: Prioritize a PTFE grade with the highest tested dielectric strength and arc resistance for applications like standoff insulators or cable jackets.

- If your primary focus is high-frequency signals: Specify a material with a certified low dielectric constant and low dissipation factor to ensure signal integrity in data cables or PCBs.

- If your primary focus is long-term reliability: Select a grade known for its thermal stability and moisture resistance to guarantee consistent performance over the product's lifespan.

Ultimately, leveraging PTFE's remarkable electrical properties requires you to verify that the specific material you choose has been manufactured and tested to meet the precise demands of your application.

Summary Table:

| Property | Value/Benefit | Key Application |

|---|---|---|

| Dielectric Strength | Up to 500 V/mil | High-voltage insulation, wire & cable jackets |

| Dielectric Constant | ~2.0 | High-frequency circuits, data cables, PCBs |

| Electrical Resistance | Extremely High | Prevents shorts, ensures component safety |

| Environmental Stability | Excellent (moisture/chemical resistant) | Long-term reliability in harsh conditions |

Need a reliable PTFE component for your electrical application?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components meet the exact electrical properties required, from prototypes to high-volume production.

Contact us today to discuss how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability