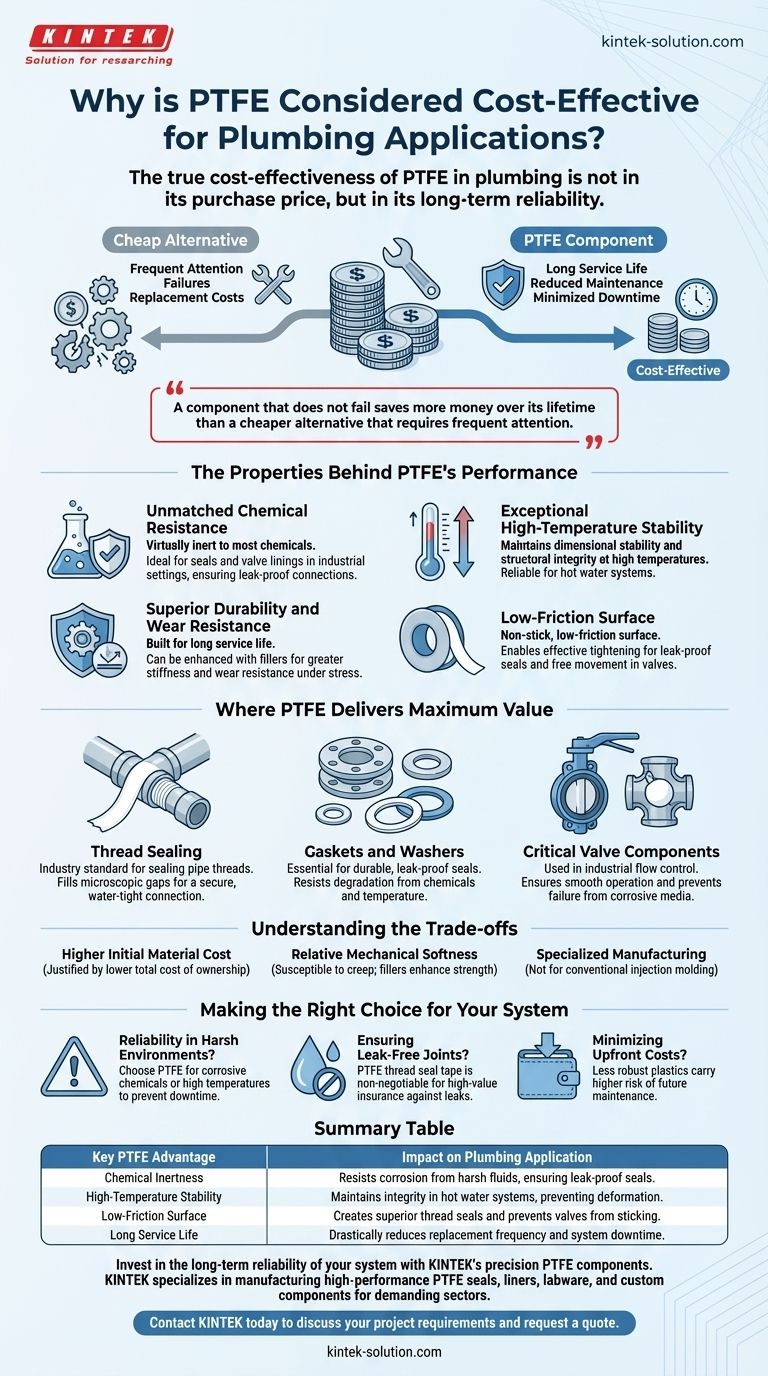

The true cost-effectiveness of PTFE in plumbing is not in its purchase price, but in its long-term reliability. Its unique combination of chemical inertness, temperature resistance, and durability means components made from Polytetrafluoroethylene (PTFE) have an exceptionally long service life, drastically reducing the costs associated with maintenance, replacement, and system downtime.

The core principle is simple: a component that does not fail saves more money over its lifetime than a cheaper alternative that requires frequent attention. PTFE is cost-effective because it is engineered to prevent costly failures in critical plumbing applications.

The Properties Behind PTFE's Performance

The value of PTFE is rooted in a specific set of material characteristics that make it uniquely suited for the demanding environment of plumbing systems, from residential homes to industrial chemical plants.

Unmatched Chemical Resistance

PTFE is virtually inert, meaning it does not react with the vast majority of chemicals. This makes it an ideal material for seals, washers, and valve linings in industrial plumbing that handles corrosive fluids, ensuring connections remain leak-proof and durable.

Exceptional High-Temperature Stability

Many plastics will deform or degrade in hot water applications. PTFE, however, maintains its dimensional stability and structural integrity at high temperatures, making it a reliable choice for components within hot water systems.

Superior Durability and Wear Resistance

Components made from PTFE are built for a long service life. For more demanding applications, PTFE can be enhanced with fillers to improve properties like stiffness and wear resistance, ensuring reliable performance under various operational stresses.

Low-Friction Surface

PTFE's non-stick, low-friction surface is a key advantage. In thread seal tape, it allows pipe threads to be tightened more effectively for a leak-proof seal. In components like check valves, it ensures parts move freely without sticking, guaranteeing consistent and efficient fluid control over time.

Where PTFE Delivers Maximum Value

PTFE is not a universal solution for every plastic part, but it excels in specific, high-stakes plumbing applications where reliability is paramount.

Thread Sealing

PTFE plumber's tape is the industry standard for sealing pipe threads. Its ability to fill microscopic gaps and its low-friction nature create a secure, water-tight connection that is easy to assemble and disassemble without damaging the threads.

Gaskets and Washers

PTFE washers and gaskets are essential for creating durable, leak-proof seals between plumbing components. Their chemical and temperature resistance prevents them from degrading, which is a common point of failure for lesser materials, especially in industrial settings.

Critical Valve Components

In industrial flow control, PTFE is used to line butterfly valves or create internal components like check valve balls. Its chemical resistance and non-stick properties ensure the valve operates smoothly and won't be compromised by corrosive media, preventing costly system failures.

Understanding the Trade-offs

No material is perfect for every situation. A clear-eyed assessment of PTFE requires acknowledging its limitations.

Higher Initial Material Cost

Components made from PTFE often have a higher upfront cost compared to parts made from more common plastics like PVC or nylon. The investment is justified by the lower total cost of ownership, not the initial purchase price.

Relative Mechanical Softness

In its pure form, PTFE is a relatively soft material that can be susceptible to "creep" or deformation under a constant heavy load. This is why fillers are often added in high-stress applications to enhance compressive strength and stiffness.

Specialized Manufacturing

PTFE is not as easily processed as common thermoplastics. It cannot be processed using conventional injection molding, which can influence component design and manufacturing costs.

Making the Right Choice for Your System

Selecting the right material requires aligning its properties with the goals of your application. PTFE's value becomes clear when long-term performance is the priority.

- If your primary focus is reliability in harsh environments: PTFE is the superior choice for handling corrosive chemicals or high temperatures, preventing costly system downtime and maintenance.

- If your primary focus is ensuring leak-free joints: PTFE thread seal tape is a non-negotiable, low-cost product that provides high-value insurance against common leaks in any plumbing system.

- If your primary focus is minimizing upfront costs for non-critical parts: A less robust plastic may be sufficient, but this choice carries a higher risk of future maintenance and failure.

Ultimately, choosing PTFE is an investment in long-term stability and peace of mind for your entire system.

Summary Table:

| Key PTFE Advantage | Impact on Plumbing Application |

|---|---|

| Chemical Inertness | Resists corrosion from harsh fluids, ensuring leak-proof seals. |

| High-Temperature Stability | Maintains integrity in hot water systems, preventing deformation. |

| Low-Friction Surface | Creates superior thread seals and prevents valves from sticking. |

| Long Service Life | Drastically reduces replacement frequency and system downtime. |

Invest in the long-term reliability of your system with KINTEK's precision PTFE components.

For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, a component that prevents failure is the most cost-effective choice. KINTEK specializes in manufacturing high-performance PTFE seals, liners, labware, and custom components that deliver unmatched chemical resistance and durability.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific needs. Don't compromise on system integrity—let our expertise in PTFE solutions provide the peace of mind your operation deserves.

Contact KINTEK today to discuss your project requirements and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers