In technical terms, PTFE stands for polytetrafluoroethylene. It is a synthetic fluoropolymer of tetrafluoroethylene, a high-performance plastic known for its exceptional properties, most famously its non-stick surface.

The name polytetrafluoroethylene (PTFE) describes its chemical structure, but its real-world significance comes from its unique combination of properties: extreme slipperiness, chemical inertness, and high-temperature resistance. Understanding these characteristics is far more important than memorizing the name.

The Story and Science Behind PTFE

The question "What does PTFE stand for?" often comes from a need to understand what this ubiquitous material actually is. The long chemical name is just the starting point.

A Serendipitous Discovery

PTFE was discovered by accident in 1938 by Dr. Roy J. Plunkett at DuPont. He was attempting to create a new, non-toxic refrigerant gas.

When a pressurized cylinder of tetrafluoroethylene gas appeared empty but still weighed the same as when it was full, he cut it open. Inside, he found a waxy, white, and incredibly slippery powder.

The gas molecules (monomers) had spontaneously linked together into long chains (polymers), creating what we now know as polytetrafluoroethylene.

Why Its Chemical Structure Matters

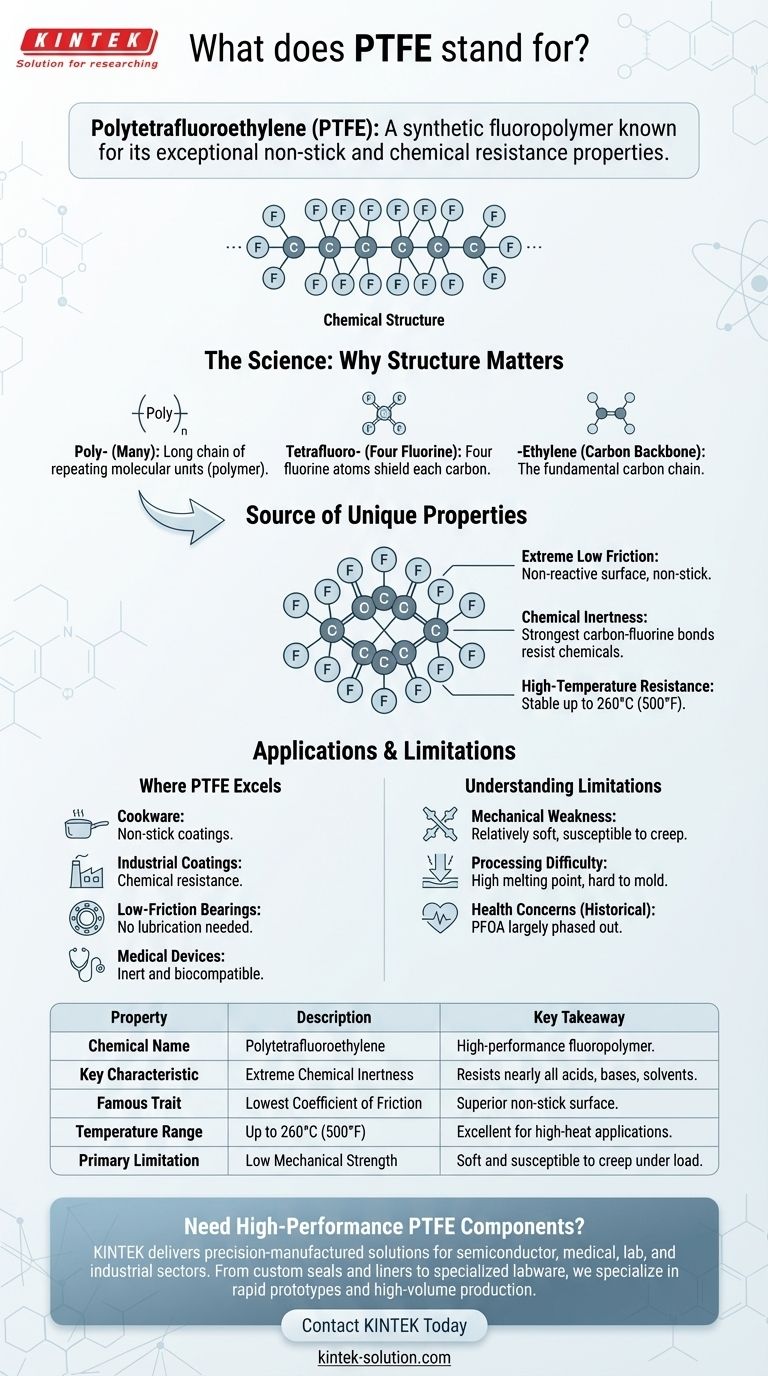

The name polytetrafluoroethylene tells you everything about its structure and, by extension, its properties.

- Poly-: This prefix means "many," indicating it's a polymer—a long chain of repeating molecular units.

- tetrafluoro-: This means "four fluorine atoms."

- -ethylene: This refers to the basic carbon backbone of the molecule.

The molecule consists of a long chain of carbon atoms, but each carbon atom is completely shielded by a tight sheath of fluorine atoms. The carbon-fluorine bond is one of the strongest in organic chemistry.

The Source of Its Unique Properties

This incredibly stable and shielded structure gives PTFE its famous characteristics.

Extreme Low Friction: The fluorine sheath is very non-reactive and does not like to stick to other molecules, creating one of the lowest coefficients of friction of any known solid. This is the "non-stick" quality.

Chemical Inertness: The strong carbon-fluorine bonds are extremely difficult to break. This makes PTFE resistant to nearly all chemicals, acids, and bases, making it invaluable for lab equipment and industrial linings.

High-Temperature Resistance: The molecular stability also means PTFE can withstand very high temperatures (up to around 260°C or 500°F) without degrading.

Common Applications and Trade-offs

While PTFE is incredibly useful, it's essential to understand where it excels and what its limitations are.

Where PTFE Excels

The unique properties of PTFE make it the ideal material for a wide range of applications.

- Cookware: Its most famous use is as the non-stick coating on pans and bakeware, under brand names like Teflon.

- Industrial Coatings: It's used to coat pipes, valves, and vessels that handle corrosive chemicals.

- Low-Friction Bearings and Gears: In mechanical systems, PTFE parts can operate without lubrication.

- Medical Devices: Its inertness and slipperiness make it suitable for catheters and surgical grafts.

- Electrical Insulation: It's an excellent electrical insulator, used in high-performance wiring for aerospace and computing.

Understanding the Limitations

No material is perfect, and it's important to be aware of the trade-offs.

Mechanical Weakness: PTFE is a relatively soft material. It has low strength and is susceptible to creep (slow deformation under stress).

Processing Difficulty: Due to its high melting point and viscosity, PTFE is difficult to mold into complex shapes compared to other plastics.

Health Concerns (Historical Context): While PTFE itself is stable and non-toxic, concerns have been raised about PFOA (perfluorooctanoic acid), a chemical once used in its manufacturing process. Modern PTFE production has largely phased out PFOA, but this history is often part of the conversation.

Making Sense of the Acronym

Understanding the material goes beyond just its name. Your focus should depend on your application.

- If you are a consumer: Focus on its non-stick and high-temperature properties for cookware, and be aware of the modern PFOA-free manufacturing standards.

- If you are an engineer or designer: Focus on its low friction, chemical inertness, and temperature resistance, while always considering its mechanical limitations.

- If you are a scientist: Focus on the strength of the carbon-fluorine bond as the fundamental reason for its extreme stability and inertness.

Ultimately, knowing that PTFE stands for polytetrafluoroethylene is less important than understanding why this unique molecule is one of the most versatile problem-solvers in modern materials science.

Summary Table:

| Property | Description | Key Takeaway |

|---|---|---|

| Chemical Name | Polytetrafluoroethylene | A high-performance fluoropolymer. |

| Key Characteristic | Extreme Chemical Inertness | Resists nearly all acids, bases, and solvents. |

| Famous Trait | Lowest Coefficient of Friction | Provides a superior non-stick surface. |

| Temperature Range | Up to 260°C (500°F) | Excellent for high-heat applications. |

| Primary Limitation | Low Mechanical Strength | Can be soft and susceptible to creep under load. |

Need High-Performance PTFE Components?

PTFE's unique properties make it ideal for solving complex challenges in the semiconductor, medical, laboratory, and industrial sectors. Whether you need custom PTFE seals, liners, or specialized labware, KINTEK delivers precision-manufactured components that meet your exact specifications.

We specialize in custom fabrication, from rapid prototypes to high-volume production runs, ensuring you get the right part with the performance you demand.

Contact KINTEK today to discuss your PTFE application and get a quote.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE perform in chemically aggressive environments? Unmatched Chemical Resistance for Demanding Applications

- What are some common uses of PTFE? Unlock Extreme Performance for Your Industry

- What certifications does the manufacturer of PTFE products have? Ensure Quality with ISO 9001 Certification

- What are the advantages of using Teflon? Achieve Superior Performance in Extreme Conditions

- How does PTFE react to ammonia? Discover Its Superior Chemical Resistance

- What benefits does Teflon coating offer in chemical manufacturing? Boost Equipment Lifespan & Purity

- What is PTFE commonly known as and when was it developed? The 'Plastics King' for Extreme Performance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation