In short, wide mouth PTFE laboratory bottles are defined by their complete PTFE construction, which grants them unparalleled chemical resistance against nearly all acids and solvents, an exceptionally wide operating temperature range from cryogenic lows to high heat, and a durable, non-stick design ideal for high-purity applications.

These bottles are not general-purpose containers; they are specialized tools engineered for the most demanding laboratory conditions where sample integrity, chemical compatibility, and extreme temperature tolerance are paramount.

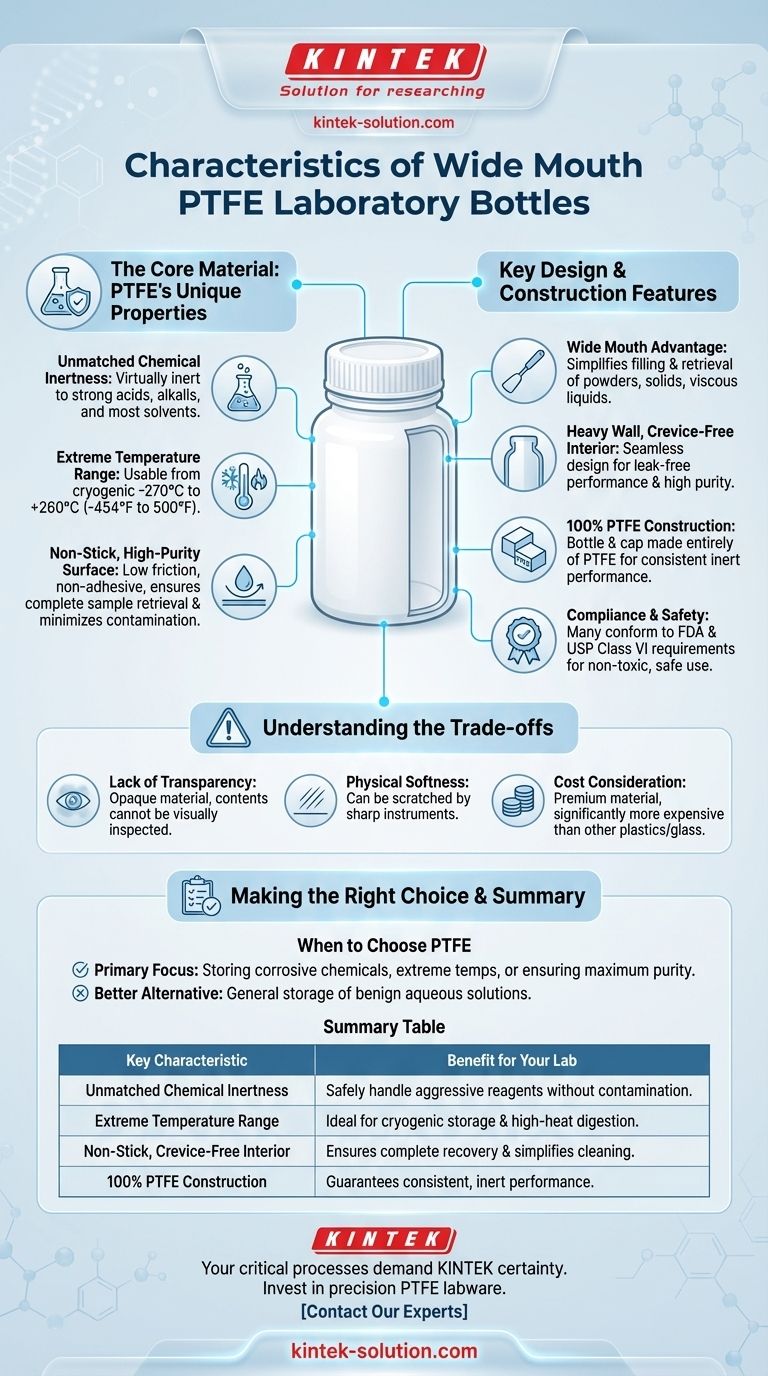

The Core Material: Understanding PTFE's Unique Properties

The characteristics of the bottle are a direct result of its material: Polytetrafluoroethylene (PTFE). This fluoropolymer provides a combination of traits that are difficult to find in any other single material.

Unmatched Chemical Inertness

PTFE is renowned for its extreme chemical resistance. It is virtually inert and does not react with strong acids, alkalis, corrosive agents like aqua regia, and most organic solvents.

This makes it an essential choice for storing, dissolving, or digesting the most aggressive chemical reagents without risk of container degradation or sample contamination.

Extreme Temperature Range

These bottles have an exceptionally broad service temperature range. They can be used continuously from cryogenic temperatures around -270°C up to 260°C (-454°F to 500°F).

They can even withstand short-term exposure to temperatures as high as 280°C, making them suitable for both deep-freeze storage and high-temperature digestion procedures.

Non-Stick, High-Purity Surface

PTFE has one of the lowest coefficients of friction of any solid, giving it a non-adhesive, non-stick surface. This property is critical in a laboratory setting.

It ensures complete sample retrieval, minimizes cross-contamination between uses, and makes cleaning easier and more effective.

Key Design and Construction Features

Beyond the base material, the physical design of these bottles is optimized for demanding lab work.

The Wide Mouth Advantage

The "wide mouth" design is a practical feature that simplifies the filling and retrieval of samples. This is especially useful when working with powders, solids, viscous liquids, or spatulas.

Heavy Wall, Crevice-Free Interior

These bottles feature heavy wall construction for enhanced durability and rigidity. The interior is seamless and crevice-free.

This smooth internal finish eliminates areas where material can become trapped, ensuring both leak-free performance and the highest level of sample purity.

100% PTFE Construction

Crucially, both the bottle and its screw cap are made entirely of PTFE. This ensures that every surface in contact with the sample offers the same elite chemical and thermal resistance, providing a secure, inert seal.

Compliance and Safety

Many high-quality PTFE bottles conform to FDA and USP Class VI requirements. This certification signifies that the material is non-toxic and safe for applications in pharmaceutical, biotech, and food-grade environments where purity is non-negotiable.

Understanding the Trade-offs

While PTFE offers exceptional performance, it's important to understand its limitations to determine if it's the right choice for your specific application.

Lack of Transparency

PTFE is opaque, meaning you cannot visually inspect the contents or volume without opening the bottle. This contrasts with glass or other transparent polymers where a quick visual check is possible.

Physical Softness

Compared to glass, PTFE is a relatively soft material. It has excellent formability and impact resistance but can be scratched or gouged by sharp instruments, which could compromise the smooth interior surface.

Cost Consideration

PTFE is a premium, high-performance polymer. Consequently, PTFE labware is significantly more expensive than its counterparts made from glass, polypropylene (PP), or high-density polyethylene (HDPE).

Making the Right Choice for Your Application

Use this guide to determine if a PTFE bottle is the appropriate tool for your goal.

- If your primary focus is storing or digesting highly corrosive chemicals: PTFE's unparalleled chemical inertness makes it the safest and most reliable choice.

- If your primary focus is working with extreme temperatures (cryogenic or high heat): PTFE's wide thermal stability is essential and outperforms almost all other plastics and standard glass.

- If your primary focus is ensuring maximum sample purity and preventing contamination: The non-stick, crevice-free, and inert nature of a 100% PTFE system is ideal.

- If your primary focus is general storage of benign aqueous solutions: A more cost-effective material like borosilicate glass or HDPE is likely a better-suited and more economical option.

Ultimately, choosing a PTFE bottle is an investment in certainty for your most critical and demanding laboratory work.

Summary Table:

| Key Characteristic | Benefit for Your Lab |

|---|---|

| Unmatched Chemical Inertness | Safely store & handle aggressive acids, solvents, and reagents without risk of contamination. |

| Extreme Temperature Range (-270°C to 260°C) | Ideal for cryogenic storage and high-temperature digestion in a single, durable container. |

| Non-Stick, Crevice-Free Interior | Ensures complete sample recovery, minimizes cross-contamination, and simplifies cleaning. |

| 100% PTFE Construction | Guarantees consistent, inert performance from the bottle to the cap seal for maximum purity. |

Are you working with aggressive chemicals or extreme temperatures?

Your critical laboratory processes demand the certainty that only high-performance PTFE components can provide. KINTEK specializes in manufacturing precision PTFE labware, including seals, liners, and custom-fabricated bottles, for the semiconductor, medical, and industrial sectors.

We ensure your most demanding applications are supported by:

- Unmatched Material Purity: Guaranteed chemical inertness for sample integrity.

- Precision Engineering: From prototypes to high-volume orders, tailored to your exact specifications.

- Reliable Performance: Built to withstand the most extreme lab conditions.

Invest in certainty for your lab. Contact our experts today to discuss your specific needs and receive a quote for custom PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables