At its core, Polytetrafluoroethylene (PTFE) is a material defined by extremes. Its exceptional properties stem from the powerful carbon-fluorine bond, making it one of the most non-reactive, heat-resistant, and low-friction solid materials known to science. Its most famous properties are its profound chemical inertness, stability across an enormous temperature range, and an incredibly low coefficient of friction—even lower than wet ice on wet ice.

PTFE is not just a material with one standout feature; it is a unique combination of elite-level properties. Its value lies in its ability to solve engineering challenges in extreme environments where nearly all other plastics and even many metals would fail due to chemical attack, high temperatures, or friction.

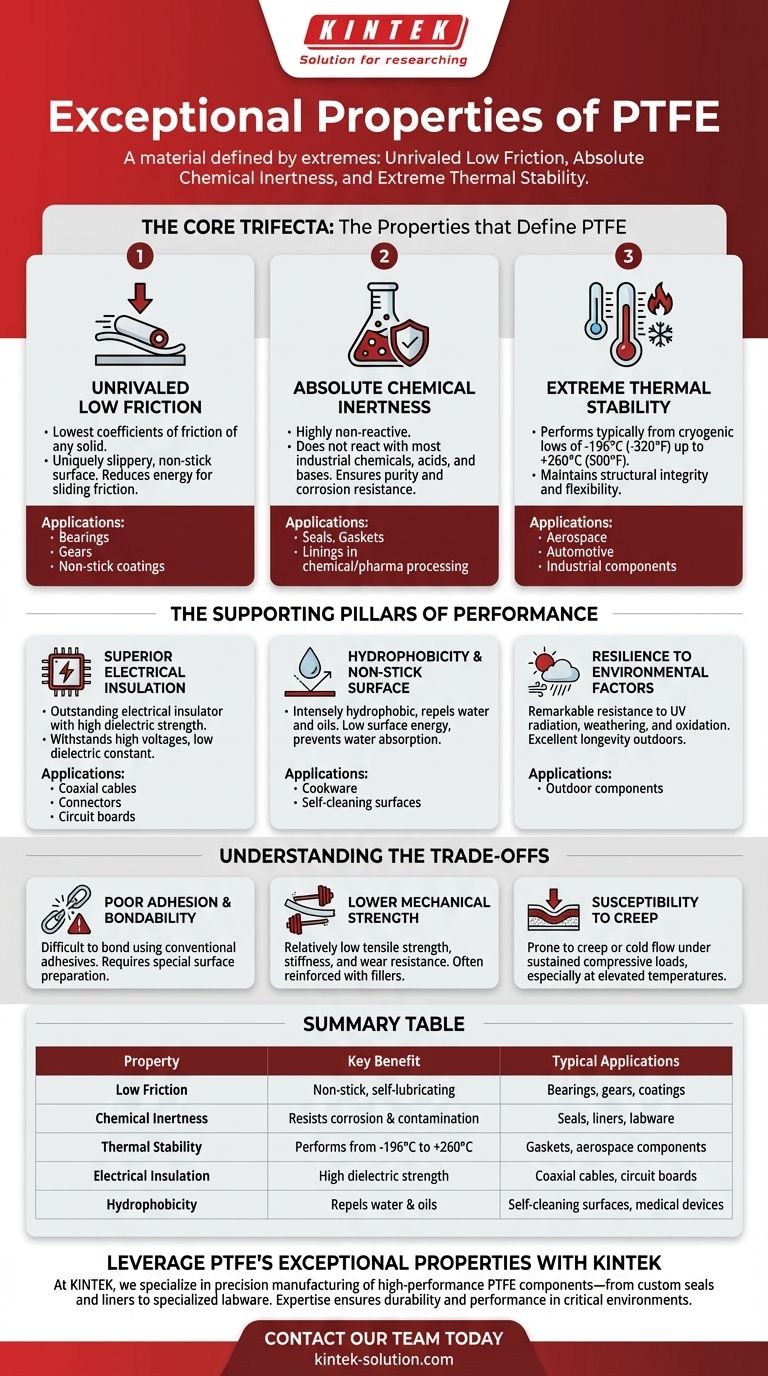

The Core Trifecta: The Properties that Define PTFE

PTFE's reputation is built on three foundational characteristics that are rarely found together in a single material. Understanding these is key to understanding its purpose.

Unrivaled Low Friction

PTFE has one of the lowest coefficients of friction of any solid. This gives it a uniquely slippery, non-stick surface.

This property is not just a surface treatment; it is an inherent quality of the material itself. It dramatically reduces the energy needed to overcome sliding friction, making it ideal for bearings, gears, and non-stick coatings.

Absolute Chemical Inertness

The material is almost completely inert, meaning it is highly non-reactive and does not react with the vast majority of industrial chemicals, acids, and bases.

This exceptional resistance makes PTFE a first-choice material for seals, gaskets, and linings in chemical processing, pharmaceutical, and semiconductor industries where purity and corrosion resistance are critical.

Extreme Thermal Stability

PTFE performs reliably across an exceptionally wide range of temperatures, typically from cryogenic lows of -196°C (-320°F) up to continuous service temperatures of +260°C (500°F).

It maintains its structural integrity and flexibility at temperatures that would cause other polymers to become brittle or melt, ensuring performance in demanding aerospace, automotive, and industrial applications.

The Supporting Pillars of Performance

Beyond the core three, several other properties make PTFE a versatile problem-solver for specialized applications.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator with high dielectric strength and a very low dielectric constant.

This means it can withstand high voltages without breaking down and does not easily store electrical energy, making it invaluable for high-frequency electronics like coaxial cables, connectors, and circuit boards.

Hydrophobicity and Non-Stick Surface

Due to its low surface energy, PTFE is intensely hydrophobic, meaning it repels water and oils.

This quality prevents water absorption and contributes to its famous non-stick properties, which are leveraged in everything from cookware to self-cleaning industrial surfaces.

Resilience to Environmental Factors

PTFE demonstrates remarkable resistance to environmental stress, including UV radiation, weathering, and oxidation.

Unlike many other plastics, it does not degrade or become brittle when exposed to sunlight and the elements over long periods, giving it excellent longevity in outdoor applications.

Understanding the Trade-offs

No material is perfect. To use PTFE effectively, it's critical to understand its limitations. Its unique strengths are accompanied by specific weaknesses.

Poor Adhesion and Bondability

The same low-friction, non-stick surface that makes PTFE so useful also makes it extremely difficult to bond to other materials using conventional adhesives.

Special surface preparation techniques, such as chemical etching, are required to create a bondable surface, adding complexity and cost to manufacturing processes.

Lower Mechanical Strength

Compared to engineering plastics like PEEK or metals, PTFE has relatively low tensile strength, stiffness, and wear resistance.

It is a soft material that can be easily scratched or deformed under high mechanical loads, which is why it is often reinforced with fillers like glass, carbon, or bronze to improve its mechanical properties.

Susceptibility to Creep

Under sustained compressive loads, especially at elevated temperatures, PTFE is prone to creep, or cold flow.

This means the material will slowly deform over time. This must be accounted for in the design of critical components like seals and gaskets to prevent eventual failure.

Making the Right Choice for Your Goal

Selecting PTFE is about matching its elite, specialized profile to an equally demanding problem.

- If your primary focus is creating non-stick, low-friction surfaces: PTFE is the benchmark material for applications like self-lubricating bearings, slide plates, and high-performance coatings.

- If your primary focus is handling highly corrosive or pure substances: Its chemical inertness makes it essential for lining pipes, valves, and vessels in the chemical and semiconductor industries.

- If your primary focus is high-frequency electrical insulation: Its excellent dielectric properties make it a top choice for insulating critical components in aerospace, telecommunications, and RF electronics.

- If your primary focus is sealing in extreme temperatures: Its wide operating temperature range ensures reliability for gaskets and seals in engines, industrial ovens, and cryogenic systems.

Ultimately, PTFE should be viewed as a high-performance solution for problems that other materials simply cannot handle.

Summary Table:

| Property | Key Benefit | Typical Applications |

|---|---|---|

| Low Friction | Non-stick, self-lubricating | Bearings, gears, coatings |

| Chemical Inertness | Resists corrosion & contamination | Seals, liners, labware |

| Thermal Stability | Performs from -196°C to +260°C | Gaskets, aerospace components |

| Electrical Insulation | High dielectric strength | Coaxial cables, circuit boards |

| Hydrophobicity | Repels water & oils | Self-cleaning surfaces, medical devices |

Leverage PTFE's Exceptional Properties with KINTEK

PTFE’s unique combination of chemical resistance, thermal stability, and low friction makes it ideal for solving extreme challenges in semiconductor, medical, laboratory, and industrial applications. At KINTEK, we specialize in precision manufacturing of high-performance PTFE components—from custom seals and liners to specialized labware.

Whether you need prototypes or high-volume production, our expertise ensures your components meet the highest standards for durability and performance in critical environments.

Ready to enhance your application with precision PTFE solutions? Contact our team today to discuss your specific requirements and discover how KINTEK can deliver reliability where it matters most.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance