Polytetrafluoroethylene (PTFE) is a cornerstone material in industries where performance under extreme conditions is non-negotiable. Its unique properties make it the material of choice for demanding applications across the chemical processing, aerospace, medical, automotive, and electronics sectors. The common thread is a need for a material that can withstand environments that would cause others to degrade.

The value of PTFE isn't just one single attribute, but its rare combination of near-total chemical inertness, a vast operating temperature range, and an extremely low coefficient of friction. This trifecta makes it a unique problem-solver in environments where other materials would quickly fail.

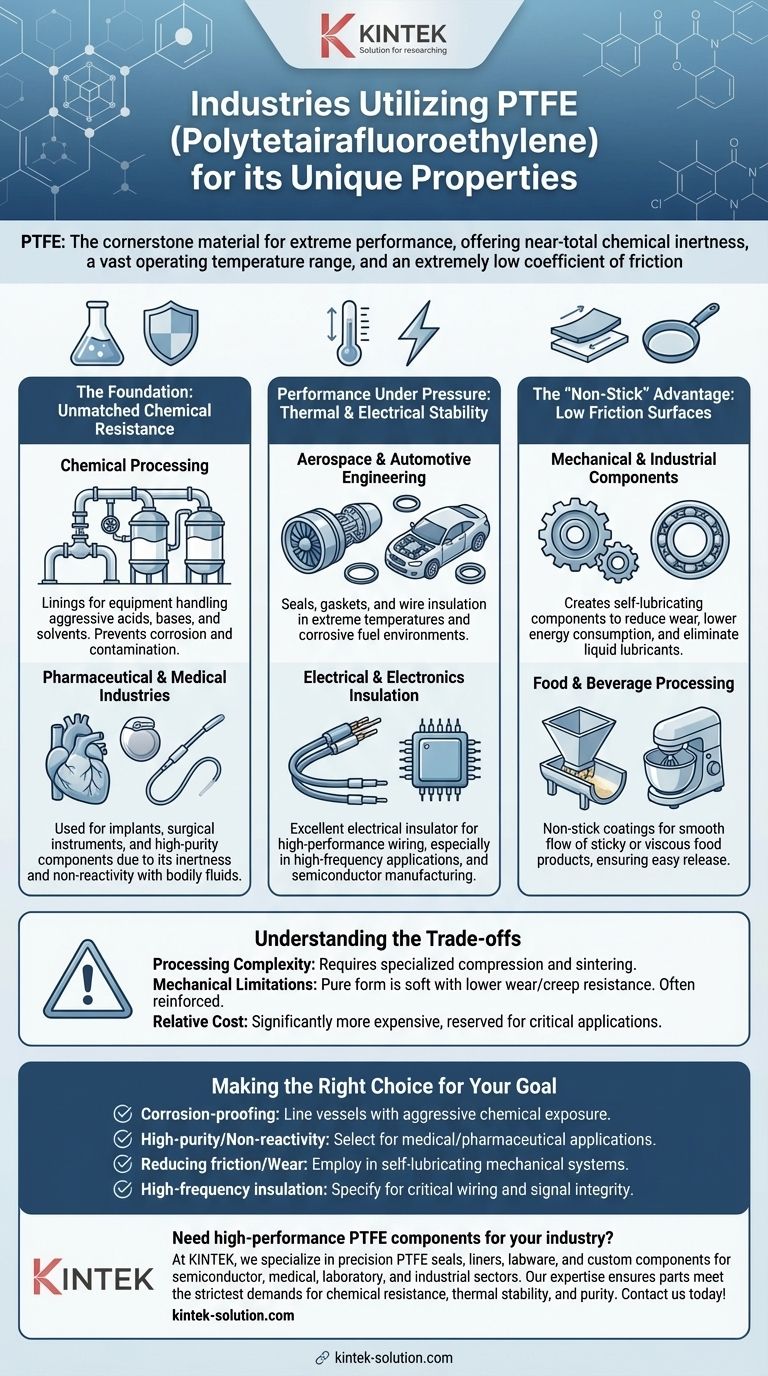

The Foundation: Unmatched Chemical Resistance

PTFE's most defining characteristic is its ability to resist attack from nearly all industrial chemicals and solvents. This makes it indispensable in sectors that handle corrosive materials.

Chemical Processing

PTFE is virtually immune to degradation from aggressive acids, bases, and organic solvents. This makes it essential for lining pipes, valves, reactors, and storage containers, preventing both equipment corrosion and product contamination.

Pharmaceutical & Medical Industries

The material's inertness and high purity are critical for medical applications. It is used for implants, surgical instruments, and catheters because it will not react with bodily fluids. In pharmaceutical manufacturing, it ensures that no impurities leach into high-purity chemical compounds.

Performance Under Pressure: Thermal & Electrical Stability

PTFE maintains its integrity and performance across an exceptionally wide range of temperatures, from cryogenic lows to high-heat engine environments.

Aerospace & Automotive Engineering

In aerospace, PTFE is used for seals, gaskets, and wire insulation that must perform reliably during extreme temperature fluctuations. In automotive systems, it is used for fuel hoses and seals that must resist both high temperatures and corrosive fuels.

Electrical & Electronics Insulation

As an excellent electrical insulator with high dielectric strength, PTFE is a top choice for insulating high-performance wiring and cables, especially in high-frequency applications. It is also used in semiconductor manufacturing due to its thermal stability and purity.

The 'Non-Stick' Advantage: Low Friction Surfaces

PTFE has one of the lowest coefficients of friction of any solid material, a property famously marketed for its "non-stick" capabilities.

Mechanical & Industrial Components

This low-friction nature is leveraged to create self-lubricating gears, bearings, and slide plates. Using PTFE reduces mechanical wear, lowers energy consumption, and eliminates the need for liquid lubricants in many systems.

Food & Beverage Processing

The non-stick quality that makes PTFE famous in kitchenware is also vital on an industrial scale. It is used to coat hoppers, chutes, and mixers to ensure that sticky or viscous food products flow smoothly without buildup.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the solution for every problem. An objective assessment requires acknowledging its limitations.

Processing Complexity

Unlike many common plastics, PTFE cannot be easily melt-processed or molded. It typically requires a specialized and more costly compression and sintering process, similar to how metal parts are made.

Mechanical Limitations

In its pure form, PTFE is relatively soft and has lower resistance to wear and creep (deformation under load) than many engineering plastics. For demanding mechanical applications, it is often reinforced with fillers like glass fiber, carbon, or bronze to improve its strength.

Relative Cost

PTFE is a high-performance polymer, and its price reflects that. It is significantly more expensive than commodity plastics, so its use is typically reserved for applications where its unique properties are a critical requirement.

Making the Right Choice for Your Goal

Selecting PTFE should be a deliberate decision based on a clear engineering need.

- If your primary focus is corrosion-proofing: Use PTFE for lining vessels, pipes, and valves that handle the most aggressive chemicals.

- If your primary focus is high-purity and non-reactivity: Select PTFE for medical tubing, pharmaceutical seals, and food-grade components.

- If your primary focus is reducing friction and wear: Employ PTFE in bearings, gaskets, and seals for smooth, self-lubricating mechanical systems.

- If your primary focus is high-frequency electrical insulation: Specify PTFE for critical wiring and semiconductor components where signal integrity is paramount.

By understanding its core strengths and limitations, you can leverage PTFE to solve engineering challenges that few other materials can address.

Summary Table:

| Industry | Primary Use of PTFE | Key Property Leveraged |

|---|---|---|

| Chemical Processing | Linings for pipes, valves, reactors | Chemical resistance, non-reactivity |

| Medical & Pharmaceutical | Implants, surgical tools, seals | High purity, biocompatibility |

| Aerospace & Automotive | Seals, gaskets, wire insulation | Thermal stability, low friction |

| Electronics | High-frequency wiring, semiconductor parts | Electrical insulation, dielectric strength |

| Food & Beverage | Non-stick coatings for equipment | Low friction, easy release |

Need high-performance PTFE components for your industry?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures parts that meet the strictest demands for chemical resistance, thermal stability, and purity.

Contact us today to discuss your specific requirements and let us provide a solution tailored to your application!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are the primary applications of PTFE? Unlocking High-Performance Solutions