At its core, the suitability of PTFE rotary shaft seals for low friction and dry running applications stems directly from two intrinsic material properties: an exceptionally low coefficient of friction and its self-lubricating nature. This unique combination allows components to slide against each other with minimal heat generation or wear, even without the presence of external lubricants.

The fundamental advantage of PTFE is that it provides a built-in lubrication mechanism at the molecular level. This eliminates the dependency on external oils or greases, enabling reliable, high-performance sealing in applications where traditional lubrication is impractical, undesirable, or simply impossible.

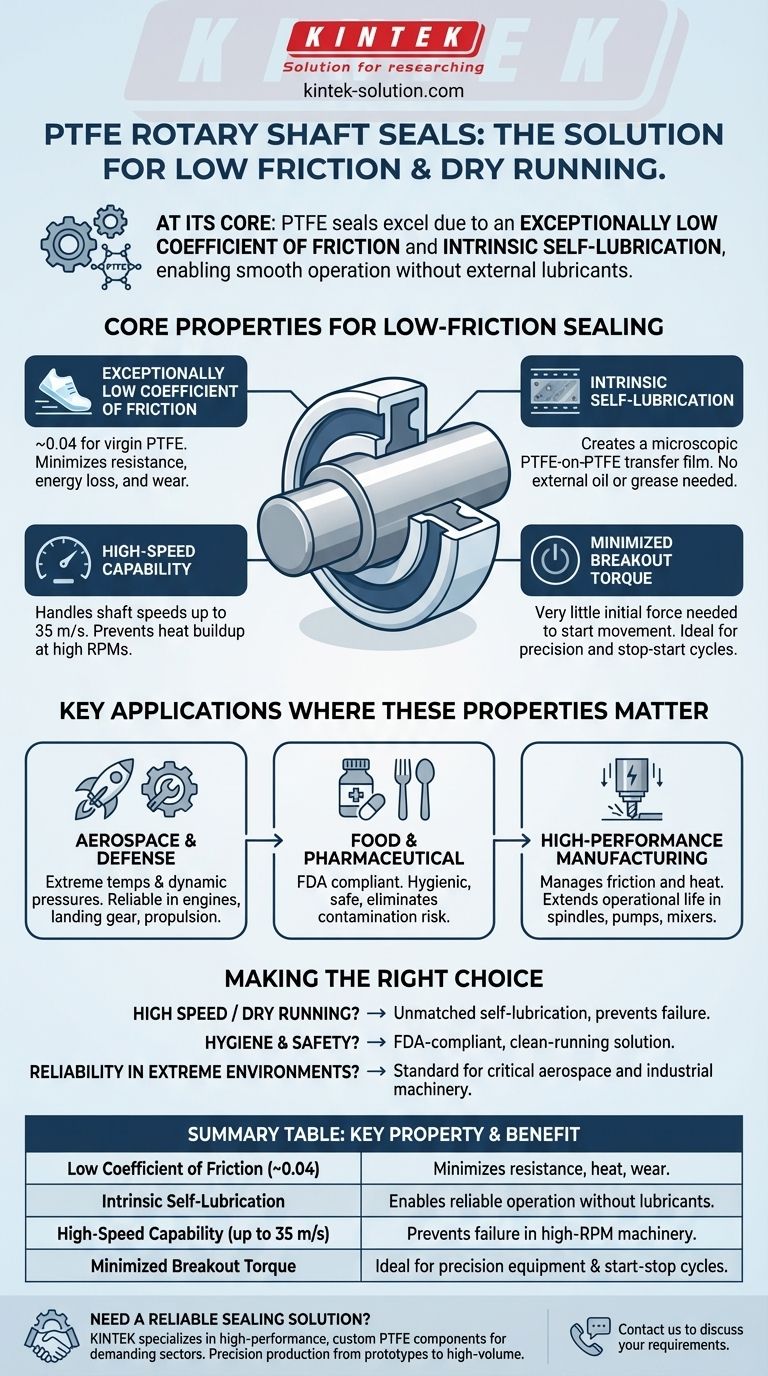

The Core Properties of PTFE for Low-Friction Sealing

To understand why PTFE excels, we must look at the specific characteristics that set it apart from other sealing materials. These properties work in concert to deliver superior performance in demanding conditions.

Exceptionally Low Coefficient of Friction

PTFE possesses a lower coefficient of friction than any other known solid material, with values as low as 0.04 for virgin PTFE.

This means that parts can slide against each other with very little resistance. This quality is essential for minimizing energy loss, heat generation, and material wear over the seal's lifespan.

Intrinsic Self-Lubrication

The material is inherently self-lubricating, which is the key to its dry-running capability.

During initial operation, a microscopic transfer film of PTFE is deposited onto the mating shaft surface. This creates a highly effective PTFE-on-PTFE interface that operates smoothly without needing external oil or grease.

High-Speed Capability

The low friction and self-lubricating properties prevent the excessive heat generation that causes other seals to fail at high speeds.

PTFE seals can successfully handle shaft surface speeds of up to 35 m/s, making them ideal for high-RPM machinery where traditional seals would quickly degrade.

Minimized Breakout Torque

Breakout torque is the initial force required to overcome static friction and start a component's movement.

Because PTFE's static and dynamic coefficients of friction are nearly identical, very little extra force is needed to get the shaft moving. This is critical for precision equipment and systems with frequent start-stop cycles.

Where These Properties Matter: Key Applications

The unique benefits of PTFE make it the material of choice in industries where performance and reliability are non-negotiable.

Aerospace and Defense

In aerospace, components must withstand extreme temperature fluctuations and dynamic pressures.

PTFE seals are used in aircraft engines, landing gear systems, and rocket propulsion, where their reliability and low maintenance needs are critical for mission success.

Food and Pharmaceutical Industries

Hygiene and safety are paramount in these sectors. PTFE rotary shaft seals are often compliant with FDA regulations.

Their self-lubricating nature eliminates the risk of product contamination from external greases, ensuring a clean and safe operating environment.

High-Performance Manufacturing

In applications like high-speed spindles, pumps, and mixers, heat is the primary enemy of seal longevity.

PTFE's ability to manage friction and heat in both dry and lubricated conditions ensures greater efficiency and extends the operational life of critical machinery.

Understanding the Key Considerations

While PTFE offers significant advantages, its successful implementation depends on understanding the context of the application. The decision to use PTFE is often driven by the need to overcome the limitations of other materials.

Demanding Operating Conditions

PTFE is specifically engineered for environments that are too hostile for conventional elastomers. Its selection is a direct response to challenges like extreme temperatures, high shaft speeds, or aggressive media.

System Longevity and Reliability

The goal of using a PTFE seal is often to enhance the overall reliability and lifespan of the machinery it protects. By reducing wear, minimizing maintenance, and preventing leaks, it serves as a critical investment in equipment longevity.

Regulatory and Purity Requirements

In applications where contamination is a concern, such as food processing or pharmaceuticals, the choice of PTFE is driven by compliance. Its ability to run dry without external lubricants is not just a performance benefit but a regulatory necessity.

Making the Right Choice for Your Application

Selecting the correct seal material is a crucial engineering decision. Your primary goal will determine if PTFE is the optimal solution.

- If your primary focus is high rotational speed or dry running: PTFE's self-lubricating properties are unmatched, preventing the heat buildup and premature failure common with other materials.

- If your primary focus is hygiene and safety: FDA-compliant PTFE provides a clean-running solution that eliminates the need for potentially contaminating external lubricants.

- If your primary focus is reliability in extreme environments: PTFE's ability to handle extreme temperatures and dynamic pressures makes it the standard for critical aerospace and industrial machinery.

Ultimately, choosing PTFE is a decision to prioritize performance and reliability in applications where conventional solutions fall short.

Summary Table:

| Key Property | Benefit for Low Friction/Dry Running |

|---|---|

| Low Coefficient of Friction (~0.04) | Minimizes resistance, heat generation, and wear |

| Intrinsic Self-Lubrication | Enables reliable operation without external lubricants |

| High-Speed Capability (up to 35 m/s) | Prevents failure in high-RPM machinery |

| Minimized Breakout Torque | Ideal for precision equipment and start-stop cycles |

Need a reliable sealing solution for demanding applications? KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your equipment runs efficiently, even in extreme conditions. Contact us today to discuss your specific requirements and benefit from our expertise in custom fabrication, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs