The single biggest advantage of Teflon washers is their inherent slipperiness. This property, known as a low coefficient of friction, is so pronounced that the material acts as its own lubricant. This allows mechanical joints to operate smoothly and reliably without the need for external oils or greases, making them exceptionally practical for low-maintenance applications and use in harsh field conditions.

The core value of a Teflon washer is not just its low friction, but its ability to deliver that low friction consistently in environments—wet, dirty, or corrosive—where traditional lubrication would fail or is simply not an option.

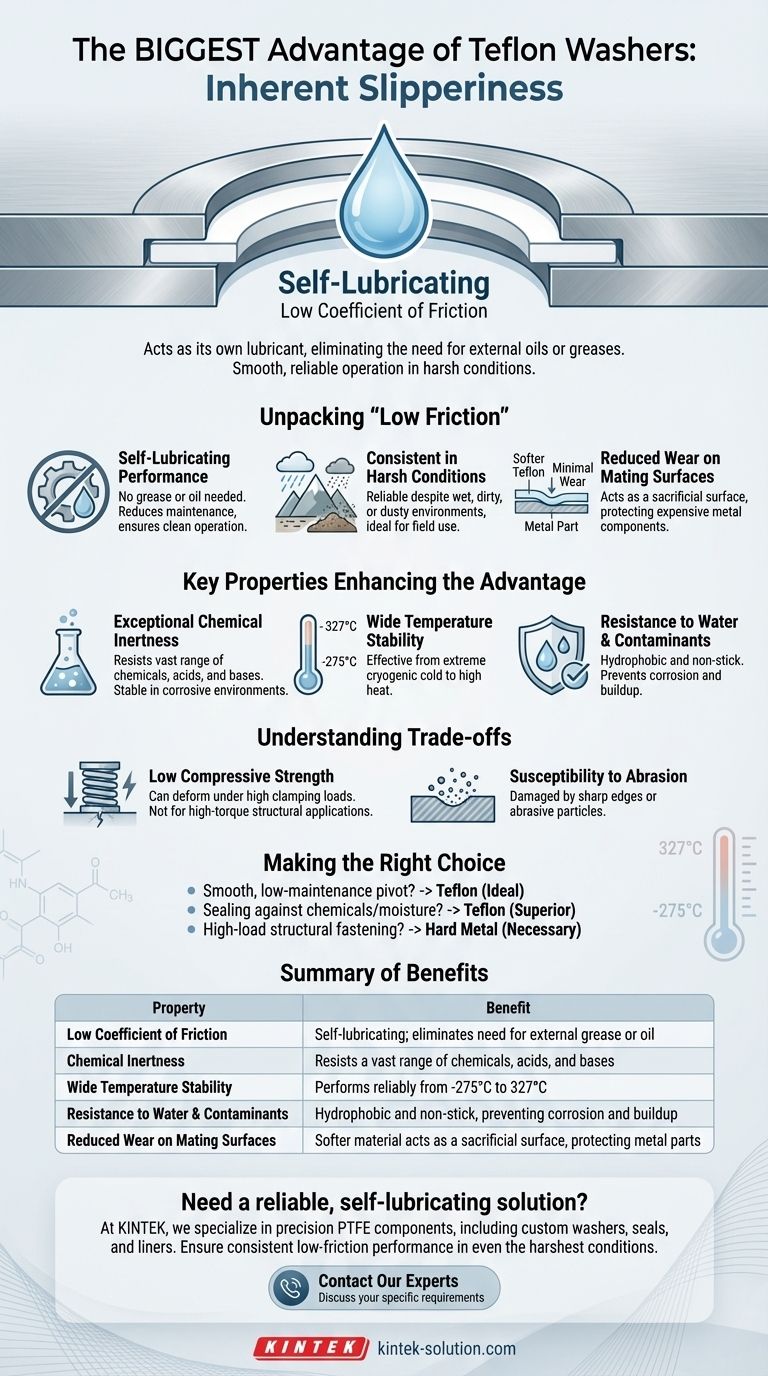

The Core Advantage: Unpacking "Low Friction"

The term "low friction" has significant practical implications. It's the primary reason Teflon (PTFE) is chosen for specific mechanical and sealing applications over metal alternatives.

Self-Lubricating Performance

Teflon's surface is naturally non-stick and slippery. This means it doesn't require periodic application of grease or oil to facilitate smooth movement between parts.

This self-lubricating quality drastically reduces maintenance requirements and provides a clean operational environment, free from lubricants that can attract dirt and grime.

Consistent Operation in Harsh Conditions

Because Teflon washers do not rely on external lubricants, their performance is unaffected by being washed, splashed with water, or exposed to dust.

This makes them ideal for "field use" applications, such as in folding knives or outdoor equipment, where reliability is critical despite exposure to the elements.

Reduced Wear on Mating Surfaces

Compared to harder materials like phosphor bronze or steel washers, Teflon is significantly softer.

When used as a pivot washer, it acts as a sacrificial surface, causing minimal to no wear on the more expensive metal components it separates. This extends the service life of the entire assembly.

Key Properties That Enhance the Advantage

Several other inherent properties of Teflon work in concert with its low friction, making it a uniquely versatile material for specific engineering challenges.

Exceptional Chemical Inertness

Teflon is resistant to a vast range of chemicals, acids, and bases.

This means its low-friction properties remain stable and reliable even in corrosive environments where oils and greases would break down and metal washers would degrade.

Wide Temperature Stability

The material remains effective across an exceptionally broad temperature range, from as low as -275°C to as high as 327°C.

This stability ensures that its performance as a washer or seal does not degrade in applications involving extreme heat or cryogenic cold.

Resistance to Water and Contaminants

Teflon is hydrophobic, meaning it repels water, which helps prevent corrosion and rust on adjacent metal parts.

Its non-stick nature also prevents contaminants from adhering to its surface, ensuring the joint remains clean and moves freely.

Understanding the Trade-offs

While its advantages are significant, Teflon is not universally superior to other materials. Its unique properties come with clear limitations that are critical to understand.

Low Compressive Strength

Teflon is a relatively soft material and is not easily compressed in a uniform way.

Under very high clamping loads, it can deform, creep, or be squeezed out of a joint. For high-torque structural applications, a hard metal washer is a better choice.

Susceptibility to Abrasion

While it resists wear from smooth metal surfaces, Teflon can be damaged by sharp edges or abrasive particles.

In environments with significant grit, a harder material like phosphor bronze might offer better durability, even if it requires lubrication.

Making the Right Choice for Your Goal

Selecting the correct washer material depends entirely on the primary demand of your application.

- If your primary focus is a smooth, low-maintenance mechanical pivot: Teflon is an ideal choice due to its self-lubricating properties and kindness to metal surfaces.

- If your primary focus is sealing against chemicals or moisture: Teflon's chemical inertness and water resistance make it a superior sealing material in plumbing and industrial systems.

- If your primary focus is high-load structural fastening: A harder material like steel or bronze is necessary to handle the compressive forces without deforming.

Ultimately, choosing a Teflon washer is a decision for low-friction reliability in environments where traditional lubricated systems would fail.

Summary Table:

| Property | Benefit |

|---|---|

| Low Coefficient of Friction | Self-lubricating; eliminates need for external grease or oil |

| Chemical Inertness | Resists a vast range of chemicals, acids, and bases |

| Wide Temperature Stability | Performs reliably from -275°C to 327°C |

| Resistance to Water & Contaminants | Hydrophobic and non-stick, preventing corrosion and buildup |

| Reduced Wear on Mating Surfaces | Softer material acts as a sacrificial surface, protecting metal parts |

Need a reliable, self-lubricating solution for your application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom washers, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get parts that deliver consistent low-friction performance in even the harshest conditions—from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can enhance your product's reliability and reduce maintenance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials