The definitive answer is E-glass. This specific formulation, also known as electrical glass, is the only type of glass used as a reinforcement filler in Polytetrafluoroethylene (PTFE). It is selected for its excellent properties as an electrical insulator, which preserves one of the core benefits of the base PTFE material.

The core purpose of adding E-glass fibers to PTFE is to drastically improve its mechanical properties—specifically its resistance to wear and "cold flow" or creep—without sacrificing the material's inherent electrical insulation and chemical inertness. This creates a high-performance composite engineered for demanding applications.

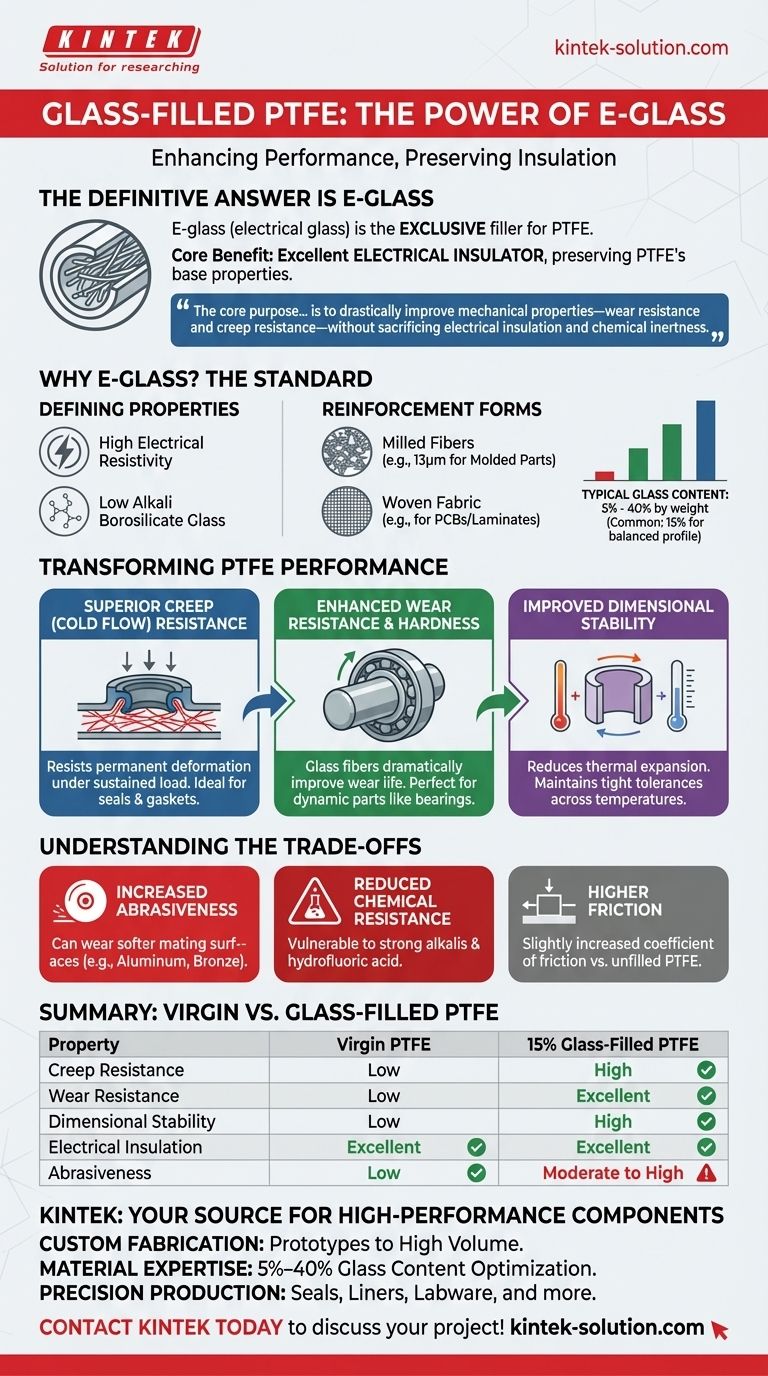

Why E-Glass is the Standard for PTFE

The choice of filler material in a polymer composite is never arbitrary. E-glass is used exclusively because its properties perfectly complement the strengths and weaknesses of virgin PTFE.

The Defining Properties of E-Glass

E-glass is a low alkali borosilicate glass. Its primary characteristic is its high electrical resistivity, which is why it's often called "electrical glass."

This property is critical because it means the resulting composite remains an excellent electrical insulator, a key reason many engineers select PTFE in the first place.

The Form of the Reinforcement

While E-glass is the only type of glass used, it can be incorporated in different forms. For molded parts like seals or bearings, it's typically added as milled fibers with an average diameter of 13µm.

For PTFE laminates, such as those used in printed circuit boards (PCBs), the E-glass is used as a woven fabric. These weaves come in various styles (e.g., 106, 1080) that offer different structural characteristics for the final sheet.

Typical Glass Content

The percentage of glass fiber added to PTFE typically ranges between 5% and 40% by weight. A common and versatile formulation is 15% glass-filled PTFE, which offers a balanced profile of enhanced properties. Higher percentages increase hardness and stability but can also increase abrasiveness.

How Glass Transforms PTFE's Performance

Adding glass fibers creates a composite material with mechanical capabilities that far exceed those of unfilled PTFE.

Superior Creep (Cold Flow) Resistance

Virgin PTFE has a tendency to deform permanently under sustained pressure, a phenomenon known as creep or cold flow. The glass fibers create an internal structural matrix that significantly resists this deformation, making it ideal for seals and gaskets under constant load.

Enhanced Wear Resistance and Hardness

The hardness of the glass fibers dramatically improves the material's resistance to wear. This makes glass-filled PTFE a superior choice for dynamic applications like bearings, piston rings, and other components involving friction and movement.

Improved Dimensional Stability

PTFE has a high coefficient of thermal expansion, meaning it changes size significantly with temperature. The inclusion of dimensionally stable glass fibers reduces this expansion, resulting in components that hold their tolerances better across a range of operating temperatures.

Understanding the Trade-offs

While highly beneficial, adding glass is not without its compromises. Acknowledging these trade-offs is crucial for proper material selection.

Increased Abrasiveness on Mating Surfaces

The hardness of the glass fibers can cause wear on softer mating surfaces, such as shafts made from stainless steel, aluminum, or bronze. For applications involving soft metals, a different filler (like bronze or carbon) may be a more appropriate choice.

Reduced Chemical Resistance (in Specific Cases)

While PTFE is famously inert, E-glass is not. The glass fibers can be attacked by strong alkaline solutions and hydrofluoric acid. In these specific chemical environments, unfilled PTFE remains the superior option.

Higher Coefficient of Friction

Glass-filled PTFE has a slightly higher coefficient of friction compared to its unfilled counterpart. While still a low-friction material, this minor increase can be a factor in highly sensitive applications.

Making the Right Choice for Your Application

Selecting the correct material hinges entirely on the primary demands of your design.

- If your primary focus is mechanical stability under load: Glass-filled PTFE is an excellent choice for seals, gaskets, and valve seats due to its superb creep resistance.

- If your primary focus is wear resistance in electrical components: The combination of E-glass reinforcement and PTFE's insulating properties is ideal for connectors, insulators, and bearings in electrical devices.

- If your application involves soft metal shafts or strong alkalis: You must carefully consider the abrasive nature and chemical limitations of glass-filled PTFE and evaluate alternatives.

Ultimately, understanding how E-glass modifies PTFE allows you to leverage the strengths of this composite for more durable and reliable components.

Summary Table:

| Property | Virgin PTFE | 15% Glass-Filled PTFE |

|---|---|---|

| Creep/Cold Flow Resistance | Low | High |

| Wear Resistance | Low | Excellent |

| Dimensional Stability | Low | High |

| Electrical Insulation | Excellent | Excellent |

| Abrasiveness on Mating Surfaces | Low | Moderate to High |

Need High-Performance Glass-Filled PTFE Components?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware, reinforced with E-glass for superior mechanical properties. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your components meet the highest standards for durability and performance.

We offer:

- Custom Fabrication: From prototypes to high-volume production runs.

- Material Expertise: Optimal selection of glass-filled PTFE formulations (5%-40% glass content) for your specific application.

- Precision Production: Components engineered for excellent creep resistance, wear resistance, and dimensional stability.

Contact KINTEK today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Parts Manufacturer Conductive Glass Substrate Cleaning Rack

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability