At its core, a PTFE-coated O-ring is a high-performance sealing solution used across a wide range of demanding industries. Its adoption is driven by its unique ability to combine the flexibility of a standard elastomer O-ring with the superior chemical resistance, low friction, and temperature stability of Polytetrafluoroethylene (PTFE). Key sectors include chemical processing, aerospace, automotive, food and beverage, and pharmaceuticals.

The fundamental value of a PTFE coating is that it enhances the performance of a standard elastomer O-ring. It solves critical challenges related to chemical exposure, high friction, and extreme temperatures that would cause a standard O-ring to fail.

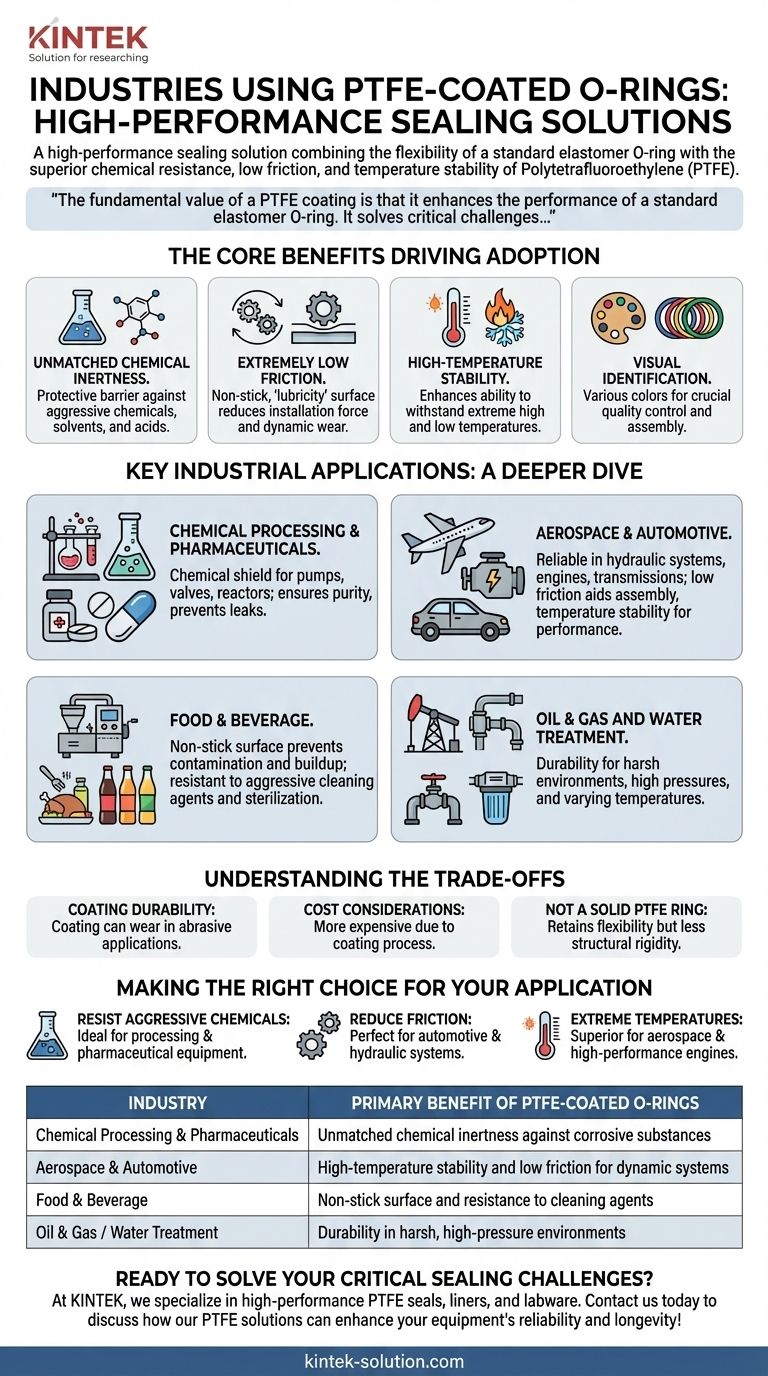

The Core Benefits Driving Adoption

The reason PTFE-coated O-rings are so prevalent is that the coating imparts specific, high-value properties to the underlying elastomer seal. Understanding these benefits clarifies why certain industries rely on them.

Unmatched Chemical Inertness

A PTFE coating acts as a protective barrier, making the O-ring resistant to a vast range of aggressive chemicals, solvents, and acids.

This property is critical in industries where seals are constantly exposed to harsh substances, preventing degradation and ensuring system integrity.

Extremely Low Friction

PTFE is famous for its non-stick, low-friction surface. This property, known as lubricity, is a primary driver for its use.

Coating an O-ring with PTFE dramatically reduces the force needed for installation, preventing tearing or damage. It also lowers friction in dynamic applications, reducing wear and extending the life of both the seal and the equipment.

High-Temperature Stability

The PTFE layer enhances the O-ring's ability to withstand extreme temperatures, both high and low, beyond the normal operating range of the base elastomer.

This makes it indispensable for applications like aerospace engines and automotive transmissions where temperature cycling is common and seal failure is not an option.

Visual Identification

PTFE coatings can be produced in various colors. This is not merely aesthetic; it serves as a crucial tool for quality control and assembly.

In complex systems like aerospace or automotive manufacturing, color-coding O-rings prevents mix-ups, ensuring the correct material is installed in the correct groove, which is vital for safety and reliability.

Key Industrial Applications: A Deeper Dive

While many industries use these seals, a few sectors depend on them for their most critical applications.

Chemical Processing & Pharmaceuticals

In this sector, equipment like pumps, valves, and reactors handle highly corrosive materials. A PTFE-coated O-ring provides a necessary chemical shield, ensuring process purity and preventing dangerous leaks.

Aerospace & Automotive

These industries demand absolute reliability under extreme conditions. PTFE-coated O-rings are used in hydraulic systems, engines, and transmissions. The low friction aids in assembly and performance, while the temperature resistance ensures the seal functions correctly from a cold start to peak operating temperatures.

Food & Beverage

Processing equipment in the food and beverage industry requires seals that are non-contaminating and can withstand aggressive cleaning agents. The non-stick property of PTFE prevents material buildup, while its chemical resistance holds up to frequent sterilization cycles.

Oil & Gas and Water Treatment

Equipment used in drilling, pumps, and filtration systems operates in harsh environments. The seals must resist chemicals, high pressures, and varying temperatures. PTFE coatings provide the durability required for these demanding applications.

Understanding the Trade-offs

While highly effective, PTFE-coated O-rings are a specialized solution with specific considerations.

Coating Durability

The PTFE layer is a coating, not the core material. In highly abrasive dynamic applications, the coating can eventually wear away, reverting the seal to the properties of its base elastomer.

Cost Considerations

These seals are more expensive than their uncoated counterparts. The additional manufacturing step of applying the coating adds cost, which must be justified by the performance requirements of the application.

Not a Solid PTFE Ring

It is critical to remember that a coated O-ring is not the same as a solid PTFE ring. It retains the flexibility and sealing properties of its elastomer core, which is an advantage, but it does not have the same structural rigidity as a solid seal.

Making the Right Choice for Your Application

Selecting the right seal depends entirely on the specific challenges of your operating environment.

- If your primary focus is resisting aggressive chemicals: A PTFE coating is an excellent choice to protect the elastomer core in chemical processing or pharmaceutical equipment.

- If your primary focus is reducing installation or dynamic friction: The inherent lubricity of the PTFE coating makes it ideal for automotive assembly or hydraulic systems.

- If your primary focus is performance in extreme temperatures: The thermal stability of the coating makes it a superior option for aerospace and high-performance engine applications.

Ultimately, choosing a PTFE-coated O-ring is a decision to invest in reliability and extend the performance limits of a standard seal for your most critical applications.

Summary Table:

| Industry | Primary Benefit of PTFE-Coated O-Rings |

|---|---|

| Chemical Processing & Pharmaceuticals | Unmatched chemical inertness against corrosive substances |

| Aerospace & Automotive | High-temperature stability and low friction for dynamic systems |

| Food & Beverage | Non-stick surface and resistance to cleaning agents |

| Oil & Gas / Water Treatment | Durability in harsh, high-pressure environments |

Ready to solve your critical sealing challenges with precision-engineered PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need custom prototypes or high-volume production, our expertise ensures reliable performance in the most demanding applications.

Contact us today to discuss how our PTFE solutions can enhance your equipment's reliability and longevity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications