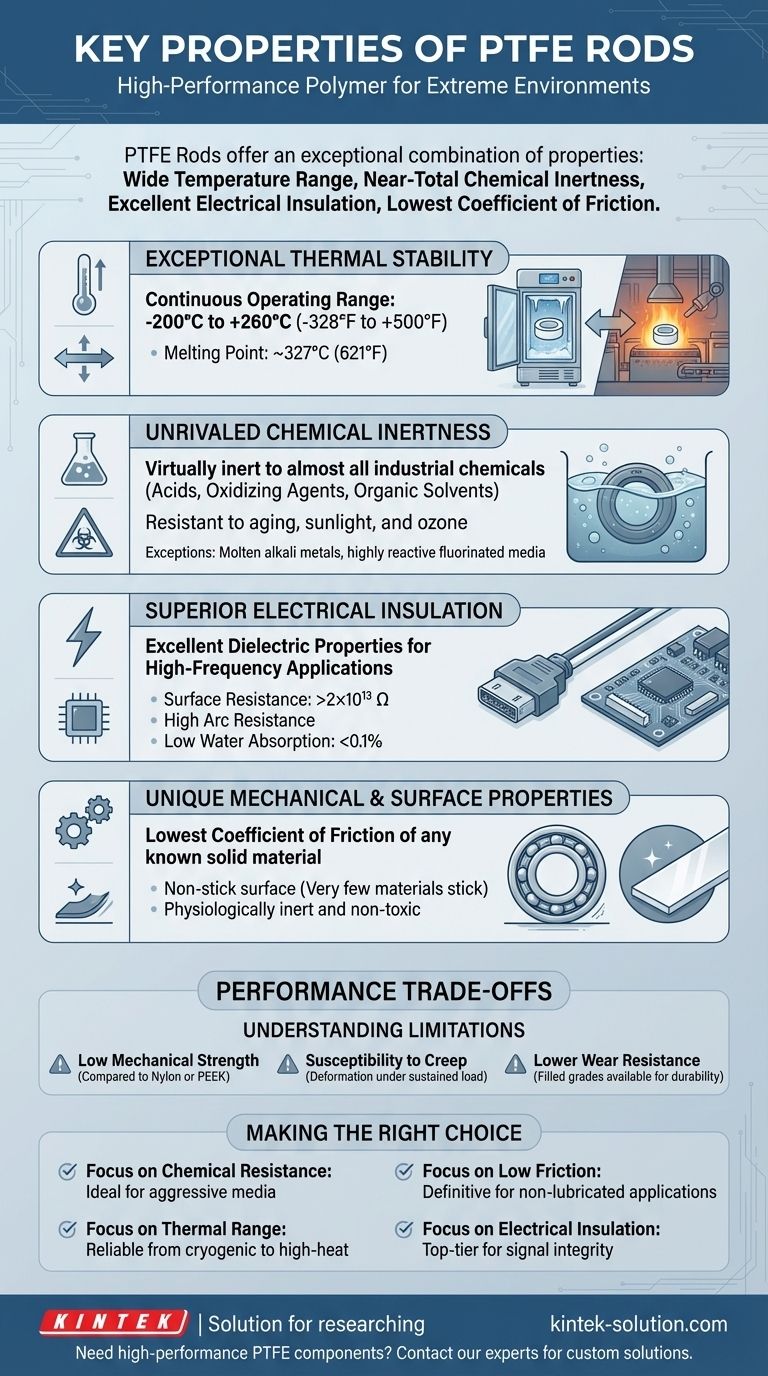

In short, PTFE rods are a high-performance polymer known for an exceptional combination of properties that make them suitable for extreme environments. Their primary characteristics include a very wide operating temperature range, near-total chemical inertness, excellent electrical insulation, and the lowest coefficient of friction of any known solid material.

PTFE, commonly known by the brand name Teflon®, is a problem-solving material. It is specified when components must operate in aggressive chemical environments, at extreme temperatures, or in applications demanding exceptionally low friction where other materials would fail.

Unpacking the Key Properties of PTFE

Polytetrafluoroethylene (PTFE) is a fluorocarbon-based polymer. Its unique molecular structure is the source of its remarkable and distinct performance characteristics, which can be grouped into four main categories.

Exceptional Thermal Stability

PTFE maintains its integrity across an incredibly broad temperature spectrum.

The material has a continuous operating temperature range from -200°C to +260°C (-328°F to +500°F). This allows it to be used in cryogenic applications as well as high-heat industrial processes.

Its melting point is approximately 327°C (621°F), providing a significant buffer for thermal excursions above its normal service temperature.

Unrivaled Chemical Inertness

PTFE is one of the most chemically resistant materials available.

It is virtually inert and resists attack from almost all industrial chemicals, including strong acids, oxidizing agents, and organic solvents. This makes it ideal for seals, gaskets, and linings in chemical processing.

The only known exceptions are molten alkali metals and highly reactive fluorinated media, which can degrade the material.

PTFE is also resistant to aging and does not degrade when exposed to sunlight or ozone, ensuring long-term stability in outdoor applications.

Superior Electrical Insulation

PTFE's electrical properties make it a first-choice material for demanding electronics.

It possesses excellent dielectric properties, meaning it is a highly effective electrical insulator. This is critical for high-frequency applications like connectors, insulators in cables, and printed circuit boards.

Its surface resistance is extremely high (greater than 2×10¹³ Ω), and it has a high arc resistance, preventing electrical breakdown.

Furthermore, PTFE exhibits very low water absorption (less than 0.1%), ensuring its electrical properties remain stable even in humid environments.

Unique Mechanical and Surface Properties

The surface and mechanical characteristics of PTFE are what make it famous.

Its most notable feature is the lowest coefficient of friction of any solid material. This creates an exceptionally slick, non-stick surface ideal for low-friction bearings, slide plates, and non-stick coatings.

This non-adhesive surface means that very few solid materials will permanently stick to it, simplifying cleaning and preventing material buildup.

Finally, PTFE is non-combustible in air and is physiologically inert and non-toxic, making it safe for use in food processing and medical applications.

Understanding the Performance Trade-offs

While its primary properties are exceptional, PTFE is not the ideal material for every situation. Understanding its limitations is critical for proper application.

Low Mechanical Strength

Compared to other engineering plastics like Nylon or PEEK, PTFE has a relatively low tensile strength and is softer. It is not suitable for high-load structural components.

Susceptibility to Creep

Under a sustained compressive load, PTFE can be subject to "creep" or cold flow. This means the material can slowly deform over time, which must be accounted for in sealing and gasket design.

Lower Wear Resistance

While PTFE has extremely low friction, its resistance to abrasive wear is relatively low. For high-wear applications, filled grades of PTFE (containing glass, carbon, or other fillers) are often used to improve durability.

Making the Right Choice for Your Application

Selecting PTFE is a decision based on needing its specific combination of elite properties to overcome a design challenge that other materials cannot.

- If your primary focus is chemical resistance: PTFE is an almost unbeatable choice for components exposed to aggressive acids, solvents, and corrosive media.

- If your primary focus is low friction: PTFE is the definitive material for non-lubricated bearings, slide surfaces, and non-stick applications.

- If your primary focus is thermal range: PTFE is one of the few polymers that performs reliably in both cryogenic and high-temperature environments.

- If your primary focus is electrical insulation: PTFE is a top-tier choice for high-frequency and high-voltage insulators where signal integrity and reliability are paramount.

Ultimately, PTFE is the go-to material for performance-critical applications where its unique strengths justify its selection over more conventional polymers.

Summary Table:

| Key Property | Performance Characteristic |

|---|---|

| Thermal Stability | Operating range: -200°C to +260°C |

| Chemical Inertness | Resistant to almost all industrial chemicals |

| Electrical Insulation | Excellent dielectric properties, high arc resistance |

| Coefficient of Friction | Lowest of any known solid material |

| Limitations | Lower mechanical strength, susceptible to creep |

Need high-performance PTFE components for your critical application?

KINTEK specializes in the precision manufacturing of PTFE rods, seals, liners, and custom labware. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering the unique benefits of PTFE—from superior chemical resistance to extreme temperature performance—in prototypes or high-volume orders.

Contact our experts today to discuss how our custom PTFE solutions can solve your most challenging design problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F