At its core, Teflon industrial coating is a high-performance fluoropolymer that provides a unique combination of properties no other single material can match. It is primarily valued for its extreme low friction, non-stick characteristics, high resistance to chemicals and heat, and excellent electrical insulation. These traits make it an indispensable solution across aerospace, medical, automotive, and general industrial applications.

The true value of Teflon coatings isn't just one single property, but their ability to solve complex engineering challenges where multiple problems—like friction, corrosion, and high temperatures—exist simultaneously.

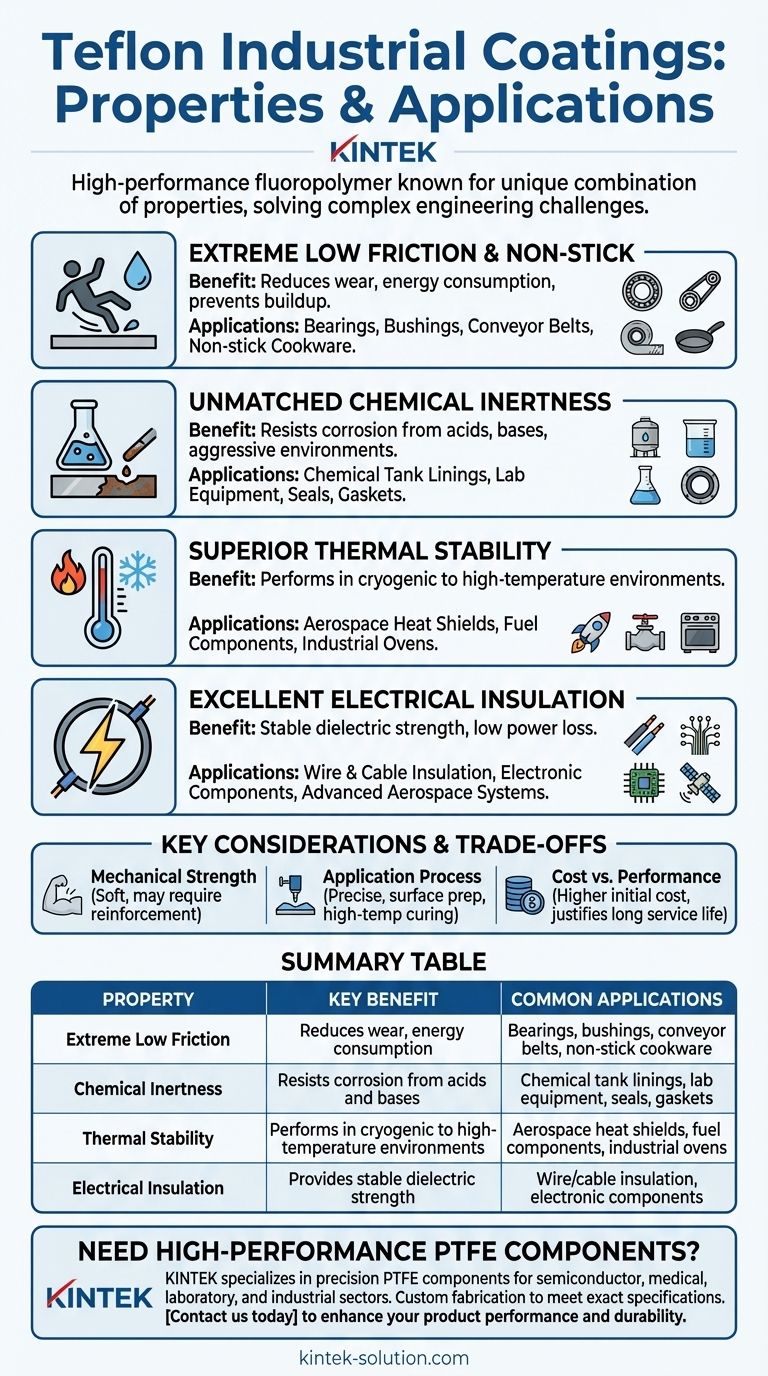

The Core Properties Driving Its Use

To understand where and why Teflon is used, we must first understand its fundamental characteristics. Each property addresses a specific set of industrial challenges.

Extreme Low Friction and Non-Stick Surfaces

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is also responsible for its famous non-stick, or hydrophobic, quality.

This property is critical for applications like bearings, bushings, and conveyor belts where it reduces wear, minimizes energy consumption, and prevents material buildup. It is also the defining feature for non-stick cookware.

Unmatched Chemical Inertness

Teflon coatings are exceptionally resistant to a vast range of chemicals, acids, and bases. They are non-reactive and do not corrode, even in highly aggressive environments.

This makes them the ideal choice for linings in chemical storage tanks and pipes, protective coatings for laboratory equipment, and durable seals and gaskets in the automotive and aerospace industries.

Superior Thermal Stability

These coatings can perform reliably across a wide and extreme temperature range. They maintain their integrity in both cryogenic conditions and at high operating temperatures where many other materials would fail.

This heat resistance is essential for parts used in aerospace applications, such as heat shields and fuel system components, as well as for various high-temperature manufacturing processes.

Excellent Electrical Insulation

Teflon is a superb electrical insulator with high dielectric strength and low power loss. Its properties remain stable across a wide range of frequencies and temperatures.

This makes it a primary material for insulating electrical wires, cables, and internal components in everything from consumer electronics to advanced aerospace systems.

Key Considerations and Trade-offs

While its benefits are significant, Teflon is not a universal solution. Understanding its limitations is key to successful application.

Mechanical Strength

Pure Teflon (PTFE) is a relatively soft material. While its low friction reduces wear in many cases, it can be susceptible to abrasion and deformation under high mechanical loads. For this reason, it is often applied as a coating or reinforced with other materials in composite structures.

Application Process

Applying an industrial Teflon coating is a precise process. It requires extensive surface preparation, specialized spray equipment, and controlled high-temperature curing to ensure proper adhesion and performance. It is not a simple paint-on application.

Cost vs. Performance

As a high-performance material, Teflon is more costly than conventional coatings. The investment is justified by its long service life and ability to perform in demanding conditions where other materials would fail quickly, preventing costly downtime and maintenance.

Making the Right Choice for Your Goal

Selecting Teflon is a decision based on solving a specific engineering problem. The coating you choose and how you apply it will depend entirely on your primary objective.

- If your primary focus is reducing friction and wear: Leverage Teflon for bearings, seals, and sliding mechanisms to improve efficiency and extend component life.

- If your primary focus is corrosion protection: Use Teflon as a liner or coating for equipment that handles aggressive chemicals, ensuring long-term integrity.

- If your primary focus is high-temperature performance: Apply it to components in engines, aerospace systems, or industrial ovens that must operate reliably in extreme heat.

- If your primary focus is electrical integrity: Specify Teflon for wire insulation and critical electrical components where signal loss or shorts are not an option.

Ultimately, Teflon's versatility makes it a powerful tool for solving some of the most difficult industrial challenges.

Summary Table:

| Property | Key Benefit | Common Applications |

|---|---|---|

| Extreme Low Friction | Reduces wear and energy consumption | Bearings, bushings, conveyor belts, non-stick cookware |

| Chemical Inertness | Resists corrosion from acids and bases | Chemical tank linings, lab equipment, seals, gaskets |

| Thermal Stability | Performs in cryogenic to high-temperature environments | Aerospace heat shields, fuel components, industrial ovens |

| Electrical Insulation | Provides stable dielectric strength | Wire/cable insulation, electronic components |

Need high-performance PTFE components tailored to your specific challenges?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise in custom fabrication ensures your components meet exact specifications for friction reduction, chemical resistance, thermal stability, or electrical insulation.

Contact us today to discuss how our PTFE solutions can enhance your product performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers