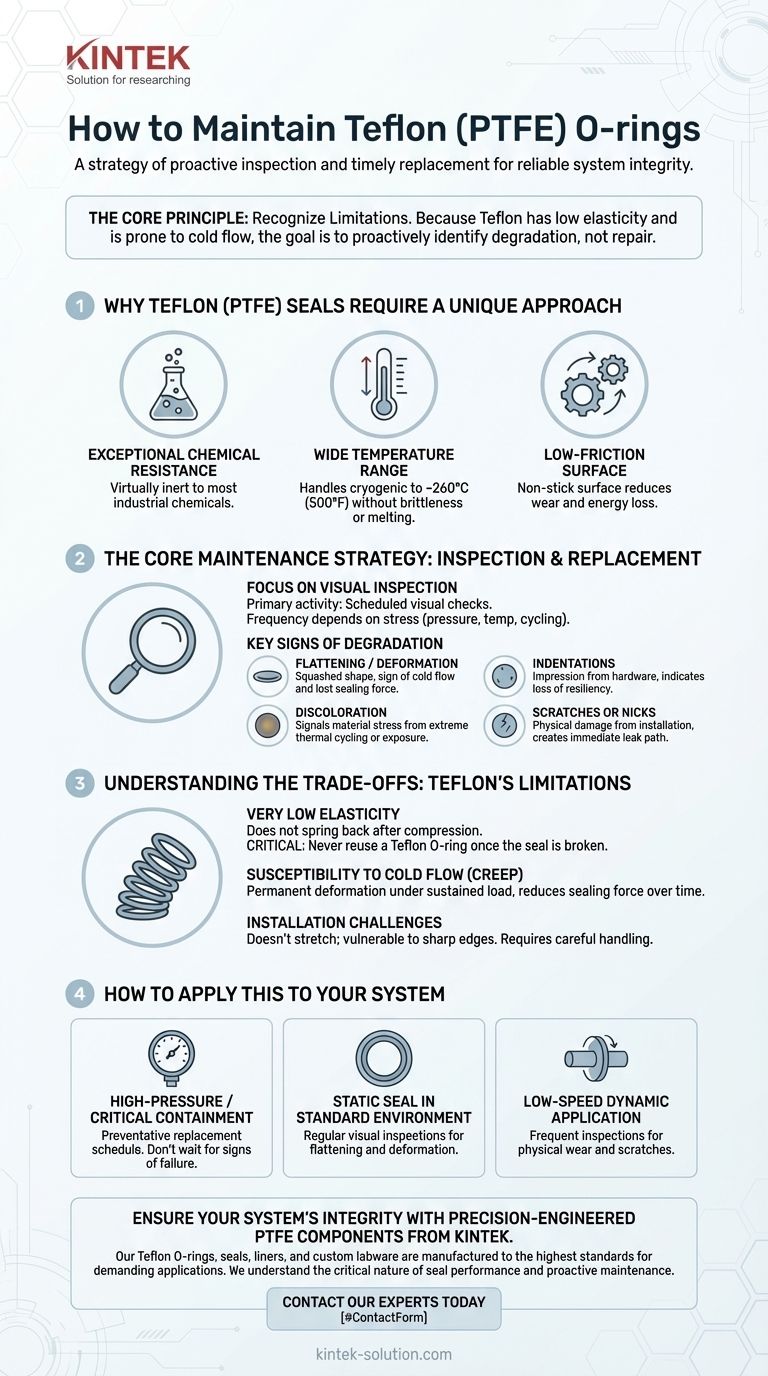

To properly maintain Teflon O-rings, you must focus on a strategy of proactive inspection and timely replacement. Unlike elastomeric (rubber) seals, Teflon (PTFE) O-rings are not repaired or reconditioned; their service life is determined by identifying signs of wear, deformation, or aging and replacing them before a failure occurs.

The core principle of Teflon O-ring maintenance is recognizing its limitations. Because Teflon has very low elasticity and is prone to permanent deformation ("cold flow"), the goal is not to fix the seal but to proactively identify signs of degradation and replace it to ensure system integrity.

Why Teflon (PTFE) Seals Require a Unique Approach

Understanding the material itself is the key to effective maintenance. Teflon is chosen for specific properties that also dictate its failure modes and maintenance needs.

Exceptional Chemical Resistance

Teflon is virtually inert to most industrial chemicals. This makes it an ideal choice for aggressive environments where a standard rubber O-ring would quickly degrade.

Wide Temperature Range

PTFE can handle a vast range of temperatures, from cryogenic lows to highs of around 260°C (500°F), without becoming brittle or melting.

Low-Friction Surface

Its famously non-stick surface means it is excellent for certain dynamic applications, reducing wear and energy loss.

The Core Maintenance Strategy: Inspection and Replacement

Because Teflon O-rings don't offer the same visual cues of decay as rubber (like cracking or becoming "gummy"), your inspection process must be meticulous.

Focus on Visual Inspection

The primary maintenance activity is a scheduled visual check. The frequency of this check depends entirely on the application's stress level—higher pressures, temperatures, and dynamic cycling require more frequent inspections.

Key Signs of Degradation

Look for specific indicators that a Teflon O-ring is nearing the end of its service life:

- Flattening or Deformation: The O-ring appears "squashed" in the groove. This is a classic sign of cold flow, where the material has permanently deformed under pressure and lost its sealing force.

- Indentations: Any impression on the O-ring surface from hardware indicates a loss of resiliency.

- Discoloration: While chemically stable, extreme thermal cycling or exposure can sometimes alter the O-ring's color, signaling material stress.

- Scratches or Nicks: Any physical damage, often occurring during installation, can create a leak path and is grounds for immediate replacement.

Understanding the Trade-offs: Teflon's Limitations

Trustworthy maintenance requires acknowledging the material's inherent weaknesses. These are not defects, but trade-offs for its unique benefits.

Very Low Elasticity

This is the most critical factor. Unlike rubber, a Teflon O-ring does not spring back to its original shape after being compressed. This is why a Teflon O-ring must never be reused once the seal has been broken.

Susceptibility to Cold Flow (Creep)

Under sustained compressive load, especially at elevated temperatures, Teflon will slowly and permanently deform. This creep reduces the sealing force over time and is a primary cause of eventual leaks in static seals.

Installation Challenges

Because it does not stretch, installing a Teflon O-ring can be difficult. It is more susceptible to being scratched or shaved by sharp edges on a shaft or in a groove, which necessitates careful handling during replacement.

How to Apply This to Your System

Your maintenance schedule should be dictated by the demands of the operating environment.

- If your primary focus is high-pressure or critical containment: Implement a schedule of preventative replacement. Do not wait for visual signs of failure, as the cost of a leak is too high.

- If your primary focus is a static seal in a standard environment: Schedule regular visual inspections, looking specifically for the flattening and deformation caused by cold flow.

- If your primary focus is a low-speed dynamic application: Inspect more frequently for signs of physical wear, scratches, and abrasion on the O-ring surface.

Ultimately, a proactive maintenance plan for Teflon O-rings is the foundation for a reliable and safe system.

Summary Table:

| Maintenance Activity | Key Focus | Signs of Degradation |

|---|---|---|

| Visual Inspection | Check for permanent deformation | Flattening, indentations, scratches |

| Replacement Strategy | Proactive, not reactive | Based on application stress (pressure, temperature) |

| Handling | Careful installation | Avoid nicks and shaving during replacement |

Ensure your system's integrity with precision-engineered PTFE components from KINTEK.

Our Teflon O-rings, seals, liners, and custom labware are manufactured to the highest standards of precision for demanding applications in semiconductor, medical, laboratory, and industrial settings. We understand the critical nature of seal performance and the importance of proactive maintenance.

Whether you need reliable standard components or custom-fabricated parts from prototype to high-volume production, KINTEK delivers the quality and consistency you need to prevent downtime and ensure safety.

Contact our experts today to discuss your specific requirements and receive a quote for high-performance PTFE solutions tailored to your application.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges