To put it simply, compression molding is preferred for certain Polytetrafluoroethylene (PTFE) applications because the material's unique properties make it incompatible with common high-volume methods like injection molding. PTFE has an extremely high melt viscosity and is sensitive to shear forces, meaning it doesn't flow like a typical plastic when heated. Compression molding works around this by compacting PTFE powder under immense pressure and then sintering it, a process ideal for creating dense, simple shapes and enhancing the mechanical properties crucial for applications like dynamic fluid sealing.

The core issue is that PTFE's high-performance characteristics also make it difficult to process. Compression molding is not just a manufacturing workaround; it is a strategic method that leverages PTFE's nature to produce robust, machinable stock shapes with superior performance in specific directions.

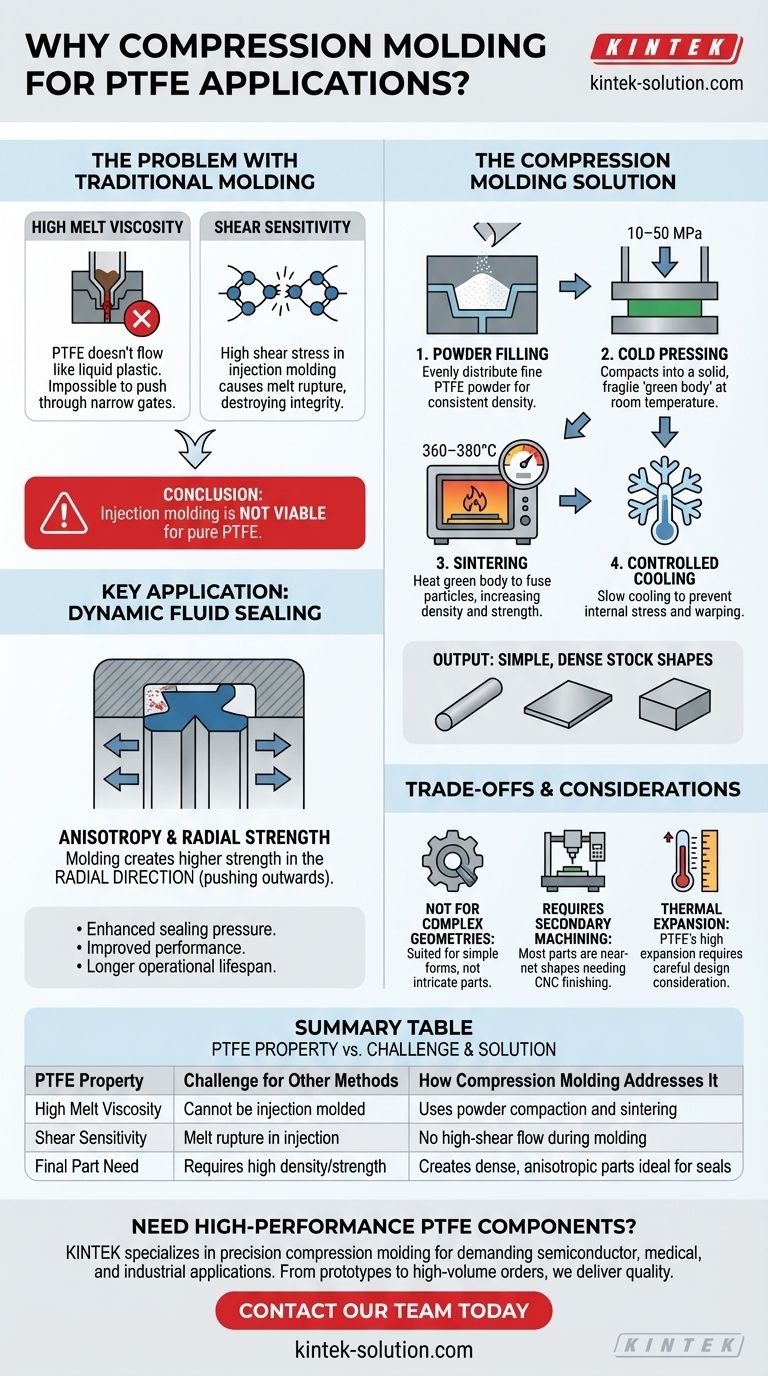

Why Traditional Molding Fails with PTFE

Before understanding why compression molding works, it is essential to grasp why more common methods are unsuitable for pure PTFE.

The High Melt Viscosity Problem

Unlike plastics that become liquid-like when heated, PTFE maintains an extremely high viscosity. It does not flow easily, making it impossible to push through the narrow gates and channels of an injection mold.

Sensitivity to Shear Stress

Attempting to force molten PTFE through a nozzle, as required in injection molding, creates high shear stress. This stress can cause melt rupture, a phenomenon where the polymer structure fractures, destroying its integrity and mechanical properties.

The Inevitable Conclusion

Because of these fundamental properties, injection molding and similar melt-processing techniques are simply not viable for manufacturing parts from pure PTFE.

The Compression Molding Process: A Strategic Fit

Compression molding is a multi-step process perfectly suited to PTFE's characteristics, transforming powder into a solid, high-density form.

Step 1: Powder Filling

The process begins by evenly distributing fine PTFE powder into a mold cavity. This ensures the final part has a consistent density.

Step 2: Cold Pressing

High pressure, typically between 10–50 MPa, is applied to the powder at room temperature. This compacts the particles into a solid but fragile pre-form, often called a "green body."

Step 3: Sintering

This is the most critical step. The green body is heated in a precisely controlled oven to a temperature between 360–380°C, just above PTFE's melting point. The particles fuse together, significantly increasing the part's density and strength.

Step 4: Controlled Cooling

The part is then cooled slowly and carefully. This final step is crucial for preventing the buildup of internal stresses that could cause cracks or warping.

The Output: Simple, Dense Shapes

This method excels at producing bulk, simple shapes—often called stock shapes—such as rods, thick sheets, gaskets, and blocks. These serve as the raw material for final parts.

Key Application: Dynamic Fluid Sealing

The benefits of compression molding are most apparent in high-performance applications like seals.

Anisotropy and Radial Strength

The pressure applied during molding creates a part with anisotropic properties, meaning its mechanical strength is not the same in all directions. For seals, this process results in significantly higher mechanical properties in the radial direction (pushing outwards from the center).

Why This Matters for Seals

A dynamic seal's primary function is to exert constant outward pressure against a housing to prevent fluid leaks. The enhanced radial strength imparted by compression molding directly improves sealing pressure, performance, and operational lifespan.

Understanding the Trade-offs

While effective, this process has clear limitations that define its use cases.

Not for Complex Geometries

Compression molding is fundamentally unsuited for creating intricate or complex parts directly from the mold. The process is designed to produce simple, solid forms.

The Need for Secondary Machining

The vast majority of compression-molded PTFE parts are considered near-net shapes. They require secondary CNC machining to achieve the final, precise dimensions and features required by the application. This makes it a two-step manufacturing process.

Thermal Expansion

PTFE has a high coefficient of thermal expansion, which must be accounted for during the design of precision parts. This property, combined with the need for machining, requires careful engineering consideration to ensure dimensional stability in the final operating environment.

Making the Right Choice for Your PTFE Application

Understanding this process allows you to align your manufacturing choice with your end goal.

- If your primary focus is creating robust seals or gaskets: Compression molding is the superior method because it enhances the critical radial mechanical properties required for sealing performance.

- If your primary focus is producing large stock shapes (rods, sheets, blocks) for machining: Compression molding is the industry-standard and most effective manufacturing process for PTFE.

- If your primary focus is high-volume, complex parts: Pure PTFE is likely the wrong material choice; investigate filled PTFE grades or alternative high-performance polymers that are suitable for injection molding.

Ultimately, selecting the right manufacturing process means choosing the one that best complements the material's intrinsic properties to achieve your desired outcome.

Summary Table:

| PTFE Property | Challenge for Other Methods | How Compression Molding Addresses It |

|---|---|---|

| High Melt Viscosity | Cannot be injection molded | Uses powder compaction and sintering |

| Shear Sensitivity | Melt rupture in injection | No high-shear flow during molding |

| Final Part Need | Requires high density/strength | Creates dense, anisotropic parts ideal for seals |

Need high-performance PTFE components? KINTEK specializes in precision compression molding of PTFE for seals, liners, and custom labware. Our expertise ensures your parts have the superior radial strength and density required for demanding applications in the semiconductor, medical, and industrial sectors. From prototypes to high-volume orders, we deliver the quality you need. Contact our team today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the benefits of PTFE with Carbon-Graphite? Achieve Superior Wear Resistance and Low Friction

- Why is understanding material limits important when choosing PTFE seals? Avoid Premature Failure

- How do PTFE and NBR oil seals compare in terms of temperature resistance? Choose the Right Seal for Extreme Heat

- What are the tensile strength and elongation properties of PTFE O-rings? Key Metrics for Demanding Seals

- How might nanotechnology improve PTFE seal performance? Achieve Unmatched Durability and Efficiency

- What are the key properties of PTFE Bellows? Achieve Unmatched Chemical & Thermal Resilience

- In which industries are PTFE diaphragms commonly used? For Superior Chemical Resistance and Purity

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech