At its core, Polytetrafluoroethylene (PTFE) packing is a critical sealing solution used in a wide range of demanding industrial applications. It is most commonly found in pumps, valves, mixers, and other mechanical equipment within the chemical processing, food and beverage, pharmaceutical, and petrochemical industries due to its unique combination of properties.

The widespread adoption of PTFE packing stems from one fundamental reality: it provides a reliable seal in environments where most other materials would quickly degrade or fail due to chemical attack, extreme temperatures, or the need for purity.

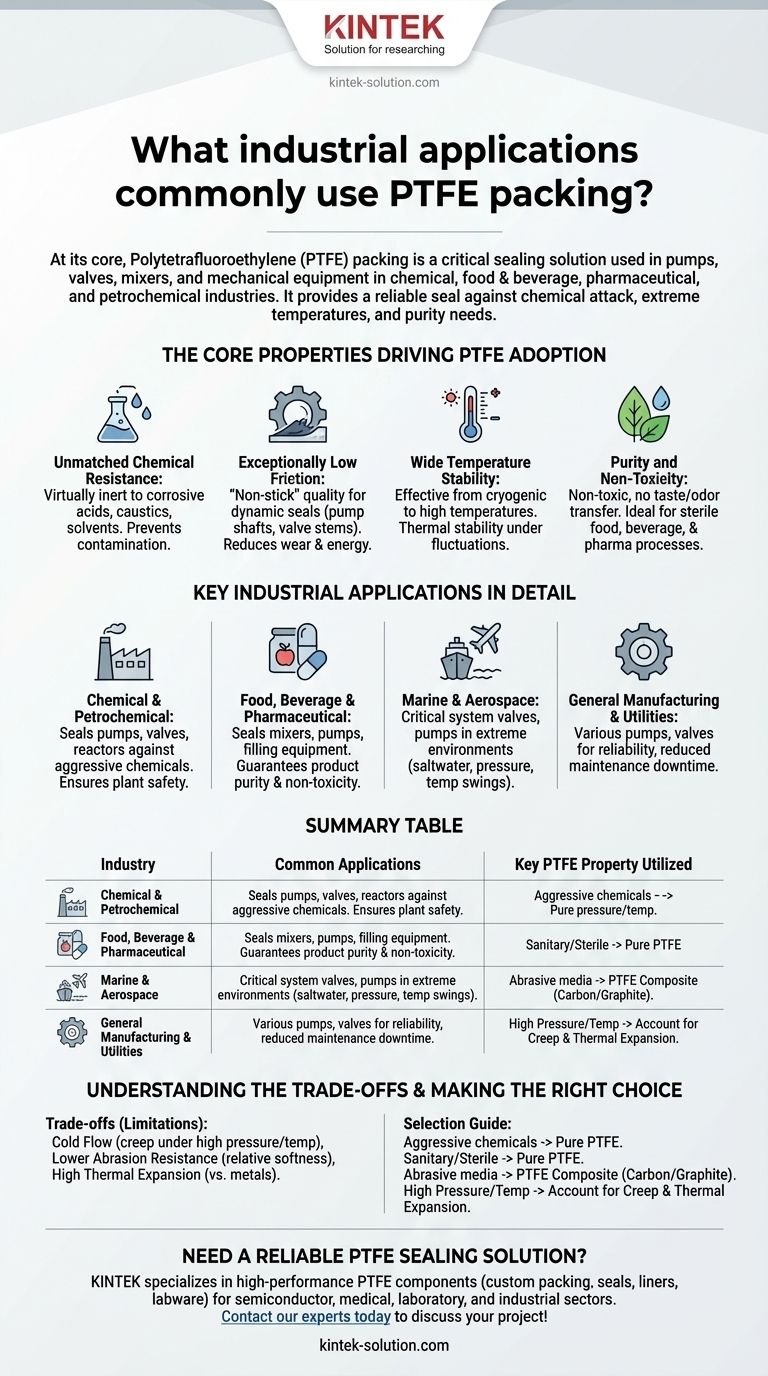

The Core Properties Driving PTFE Adoption

To understand where PTFE packing is used, one must first understand why it is chosen. Its utility is not based on a single feature but on a powerful combination of characteristics that make it uniquely suited for challenging operational conditions.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it an essential material for equipment that handles corrosive acids, caustics, and aggressive substances.

Its non-reactive nature ensures the integrity of the seal and prevents process contamination, which is critical in chemical reactors, mixers, and transfer pumps.

Exceptionally Low Friction

Often recognized by its brand name Teflon, PTFE has one of the lowest coefficients of friction of any solid material. This "non-stick" quality is vital in dynamic sealing applications like rotating pump shafts and reciprocating valve stems.

This low-friction surface reduces wear on moving parts, minimizes heat generation, and lowers the energy required to operate the equipment, extending its service life.

Wide Temperature Stability

PTFE packing performs reliably across an exceptionally broad temperature range. It remains effective in cryogenic applications as well as in high-temperature processes common in manufacturing and aerospace.

This thermal stability ensures the seal remains intact and effective despite significant fluctuations in operational temperatures.

Purity and Non-Toxicity

For industries like food, beverage, and pharmaceuticals, preventing product contamination is the highest priority. PTFE is non-toxic and does not impart taste, color, or odor to the materials it contacts.

This makes it an ideal choice for sealing processing equipment where sterile and sanitary conditions are legally and operationally mandated.

Key Industrial Applications in Detail

The unique properties of PTFE translate directly into its use across several key sectors where performance and reliability are non-negotiable.

Chemical and Petrochemical Processing

This is the primary domain for PTFE packing. It is specified for sealing pumps, valves, and fittings that manage a constant flow of corrosive chemicals, from aggressive acids to industrial solvents. Its resilience prevents costly leaks and ensures plant safety.

Food, Beverage, and Pharmaceutical Manufacturing

In these highly regulated industries, PTFE is used to seal mixers, pumps, and filling equipment. Its non-toxic and non-reactive properties guarantee that the final product remains pure and uncontaminated, meeting stringent health and safety standards.

Marine and Aerospace

Equipment in marine and aerospace applications faces extreme environmental stress, including saltwater corrosion, high pressures, and wide temperature swings. PTFE packing provides a durable, long-lasting seal that can withstand these harsh conditions in critical systems.

General Manufacturing and Utilities

Across general industry, including pulp and paper plants and power generation facilities, PTFE packing serves as a versatile sealing solution. It is used in a variety of pumps and valves to improve equipment reliability and reduce maintenance downtime.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations to ensure proper application.

Tendency for Cold Flow

Under high, continuous pressure, especially at elevated temperatures, PTFE can be prone to "creep" or cold flow. This means the material may slowly deform over time, which can potentially compromise the seal's integrity if not accounted for in the system's design.

Lower Abrasion Resistance

Compared to harder materials, PTFE is relatively soft. In applications involving abrasive slurries or high levels of particulate matter, pure PTFE packing may wear more quickly. In such cases, composite packings infused with carbon or graphite are often used to enhance durability.

High Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. Engineers must account for this during design to ensure that the seal remains effective as equipment heats and cools during operational cycles.

Making the Right Choice for Your Goal

Selecting the correct sealing material is a critical engineering decision that directly impacts operational safety, efficiency, and cost.

- If your primary focus is handling aggressive chemicals: PTFE's unparalleled chemical inertness makes it the default, most reliable choice.

- If your primary focus is a sanitary or sterile process: The purity and non-toxic nature of PTFE packing are essential for food, beverage, and pharmaceutical applications.

- If your equipment operates with abrasive media: Consider a PTFE composite packing reinforced with materials like carbon or graphite to improve wear resistance.

- If your application involves high pressure and temperature: Ensure the system is designed to accommodate PTFE's potential for creep and thermal expansion to maintain a long-term seal.

Ultimately, understanding the fundamental properties of PTFE allows you to leverage its strengths and design a more reliable and efficient industrial system.

Summary Table:

| Industry | Common Applications | Key PTFE Property Utilized |

|---|---|---|

| Chemical & Petrochemical | Pumps, Valves, Reactors | Unmatched chemical resistance |

| Food, Beverage & Pharmaceutical | Mixers, Filling Equipment, Pumps | Purity and non-toxicity |

| Marine & Aerospace | Critical System Valves, Pumps | Wide temperature stability, corrosion resistance |

| General Manufacturing & Utilities | Various Pumps, Valves | Low friction, reliability |

Need a Reliable PTFE Sealing Solution?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including custom packing, seals, liners, and labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We understand the critical role a perfect seal plays in your operation's safety, efficiency, and product purity. Whether you need a prototype for a new process or high-volume production, our custom fabrication expertise ensures you get a solution tailored to your specific chemical, temperature, and pressure requirements.

Let us help you enhance your system's reliability. Contact our experts today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance