The key indicators of a failing PTFE expansion bellow are often visible or audible. Look for physical damage like cracks, evidence of leaks near the flanges, a noticeable loss of flexibility, or an increase in system noise and vibration. These signs signal that the component's integrity is compromised and it's time for a replacement.

While PTFE bellows have a typical lifespan, replacement should be dictated by tangible signs of degradation. Proactive inspection for cracks, leaks, and changes in system dynamics is the most reliable strategy to prevent catastrophic failure.

Why Bellows are Critical System Components

To understand why failure matters, it's important to recognize the primary function of a PTFE expansion bellow. They are not simple connectors; they are dynamic, engineered components.

Accommodating System Movement

The core purpose of an expansion bellow is to absorb movement in a piping system. This movement is typically caused by thermal expansion and contraction as temperatures fluctuate.

Without this flexibility, the rigid pipes would be subjected to immense stress, leading to potential cracks, flange failure, or damage to connected equipment.

Isolating Vibration and Noise

Bellows also act as dampers, absorbing mechanical vibration and noise from pumps, motors, or other equipment. This isolation prevents the transfer of harmful energy throughout the rest of the system.

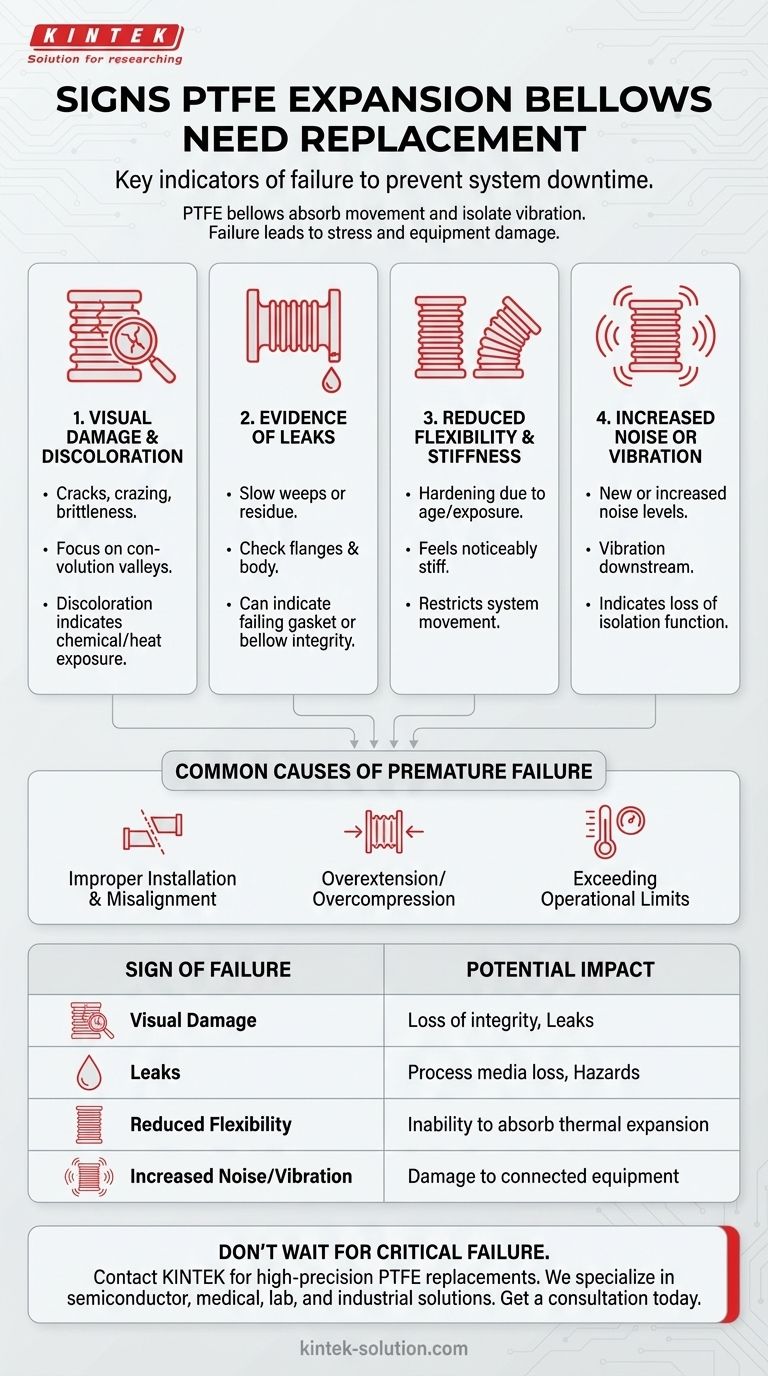

Key Indicators of Failure

A regular inspection schedule is the most effective way to identify a failing bellow before it causes a major issue. Focus your attention on these four distinct signs.

Visual Damage: Cracks and Discoloration

This is the most direct evidence of wear. Carefully inspect the entire surface of the bellow, especially in the valleys of the convolutions where stress is highest.

Look for hairline cracks, crazing, or any signs of brittleness. Discoloration can also indicate chemical attack or excessive heat exposure.

Evidence of Leaks

Leaks often begin as slow weeps before becoming catastrophic failures. Check the flange connections and the body of the bellow for any residue, drips, or signs of the process media.

A leak at a connection point can indicate a failing gasket, but it can also be caused by a loss of integrity in the bellow itself, which prevents a proper seal.

Reduced Flexibility and Stiffness

A healthy bellow should be pliable. Over time, due to age, chemical exposure, or temperature, the PTFE material can harden.

If the bellow feels noticeably stiff or appears to be restricting system movement instead of absorbing it, its service life is over. It is no longer performing its primary function.

Increased Noise or Vibration

A bellow that has become rigid will stop effectively isolating vibration. If you notice a new or increased level of noise or vibration downstream from the bellow, it is a strong indicator that the component has stiffened and needs replacement.

Common Causes of Premature Failure

While bellows have a typical service life of 5-10 years, certain conditions can drastically shorten this window. Understanding these causes is key to prevention.

Improper Installation and Misalignment

This is one of the most frequent causes of early failure. If the bellow is installed in a misaligned pipeline, it is subjected to constant lateral stress that it was not designed to handle.

Always ensure pipes are properly aligned before installing the bellow. The bellow should not be used to correct for pre-existing alignment issues.

Overextension or Overcompression

Every bellow has specified limits for movement. Stretching or compressing the unit beyond these manufacturing guidelines during installation or operation places extreme stress on the material, leading to premature cracking.

Exceeding Operational Limits

Operating the system at temperatures or pressures higher than the bellow's rating will accelerate material degradation. Similarly, using a bellow with a process fluid that is chemically incompatible with PTFE will cause it to break down rapidly.

Making the Right Replacement Decision

Your strategy for replacement should be proactive and aligned with your system's operational demands. A simple "run to failure" approach is rarely the correct one.

- If your primary focus is preventing unplanned downtime: Implement a regular inspection schedule and replace bellows at the first sign of cracking, stiffness, or leaking, regardless of age.

- If your primary focus is budget optimization: Plan for replacements based on the typical 5-10 year lifespan, but use visual inspections to prioritize the most stressed or critical units first.

- If you are commissioning a new system: Ensure meticulous adherence to manufacturer installation guidelines, paying close attention to alignment and torque specifications to maximize the bellow's service life from day one.

Ultimately, treating PTFE bellows as critical, inspectable assets rather than "fit-and-forget" components is the key to a reliable and safe system.

Summary Table:

| Sign of Failure | What to Look For | Potential Impact |

|---|---|---|

| Visual Damage | Cracks, crazing, discoloration on the bellow | Loss of integrity, leading to leaks |

| Evidence of Leaks | Residue or drips at flanges or bellow body | Process media loss, safety hazards |

| Reduced Flexibility | Bellow feels stiff, restricts movement | Inability to absorb thermal expansion |

| Increased Noise/Vibration | New or louder sounds from the system | Damage to connected equipment |

Don't wait for a critical failure.

If you're observing any of these warning signs, it's time for a reliable replacement. KINTEK specializes in manufacturing high-precision PTFE components, including custom expansion bellows for the semiconductor, medical, laboratory, and industrial sectors.

We ensure your new bellow is fabricated to exact specifications, from prototypes to high-volume orders, guaranteeing optimal performance and longevity for your specific application.

Contact KINTEK today for a consultation and let our expertise help you maintain a safe, efficient, and reliable system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials