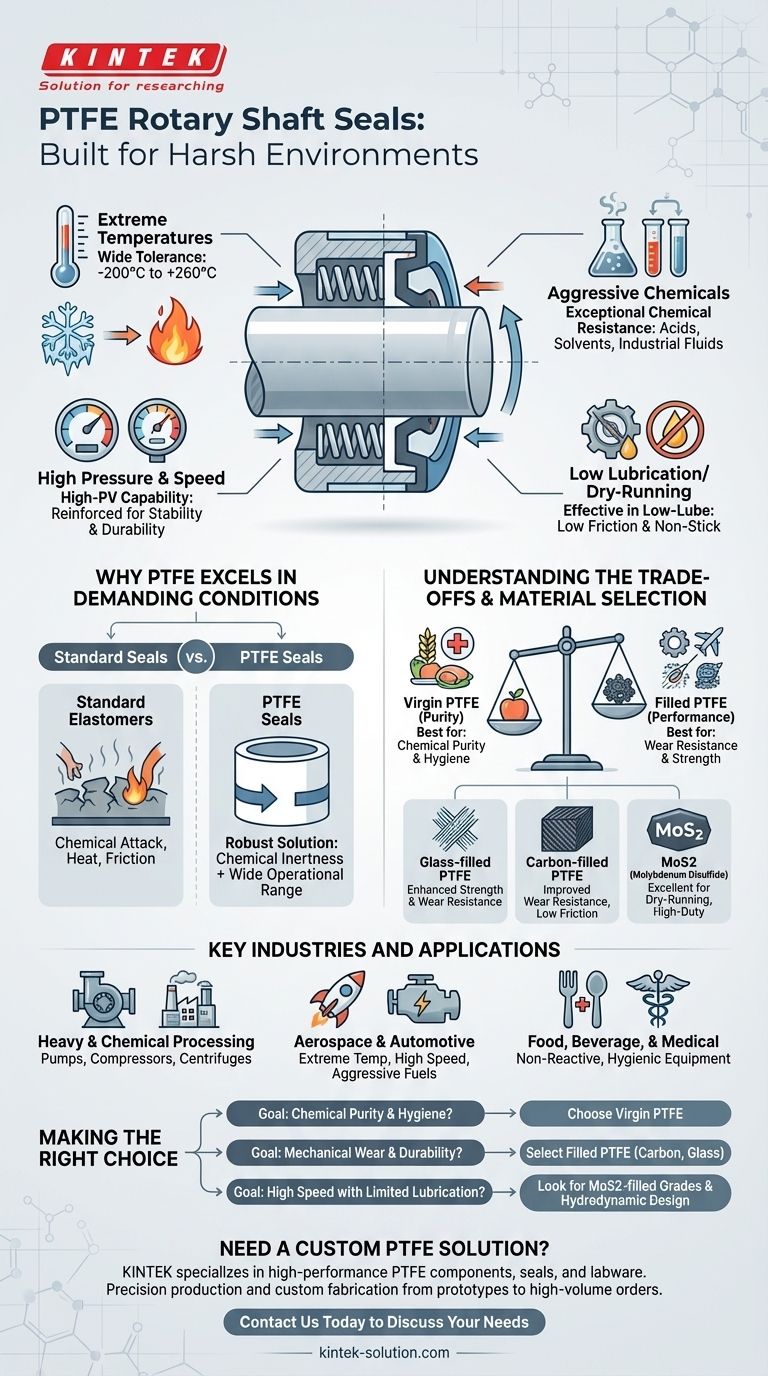

In short, PTFE rotary shaft seals are engineered for harsh operational environments where traditional elastomeric seals would quickly fail. They are the definitive choice for applications involving aggressive chemicals, extreme temperatures ranging from -200°C to +260°C, high rotational speeds, and significant pressures. Furthermore, their low-friction properties make them uniquely suited for conditions with insufficient lubrication or even dry-running scenarios.

The core problem these seals solve is ensuring equipment reliability under extreme operating conditions. While standard seals fail due to chemical attack, temperature degradation, or high friction, PTFE seals provide a robust and durable solution by combining chemical inertness with a vast operational range.

Why PTFE Excels in Demanding Conditions

The suitability of PTFE seals comes from the inherent properties of the material itself, which can be enhanced with specific fillers to meet precise application demands.

Exceptional Chemical Resistance

PTFE is one of the most chemically inert materials used in engineering. This makes it impervious to a wide range of aggressive media, including acids, solvents, and industrial chemicals.

This property is critical in industries like chemical processing, oil and gas, and pharmaceuticals, where seal integrity cannot be compromised by the processed fluids.

Wide Temperature Tolerance

PTFE seals maintain their structural integrity and sealing performance across an exceptionally broad temperature spectrum, from cryogenic lows of -200°C (-328°F) to highs of +260°C (+500°F).

This stability prevents the material from becoming brittle at low temperatures or degrading at high temperatures, a common failure point for rubber-based seals.

High-Pressure and High-Speed Capability

Standard seal materials can deform or wear rapidly under high-pressure and high-speed (high PV) conditions. PTFE, especially when reinforced with fillers, withstands these forces effectively.

Flexible lip designs, such as hydrodynamic return feeds, can be incorporated to further enhance performance at higher speeds, ensuring a stable and reliable sealing interface.

Effectiveness in Low-Lubrication Environments

The inherently low coefficient of friction of PTFE allows it to function effectively with minimal lubrication or in dry-running applications.

This non-stick characteristic prevents the seal from generating excessive heat and wear, significantly extending the service life of both the seal and the equipment in challenging conditions like screw compressors.

Key Industries and Applications

The unique combination of these properties makes PTFE rotary shaft seals essential components across a diverse range of high-stakes industries.

Heavy and Chemical Processing

In pumps, blowers, rotary compressors, and centrifuges, these seals handle corrosive fluids and high operational demands, reducing maintenance downtime and extending equipment life.

Aerospace and Automotive

Applications in aerospace and high-performance motorsports leverage PTFE's ability to withstand extreme temperatures, high speeds, and aggressive fuels or lubricants.

Food, Beverage, and Medical

The non-reactive and hygienic properties of certain PTFE grades make them ideal for food processing, dairy, and medical equipment where preventing contamination is paramount.

Understanding the Trade-offs and Material Selection

Choosing the right PTFE seal is not a one-size-fits-all process. The performance of the seal is highly dependent on the specific grade of PTFE and the seal design.

The Importance of Fillers

While virgin PTFE is excellent for its purity and chemical resistance, it can be mechanically soft. Fillers are added to enhance specific properties for more demanding applications.

- Glass-filled PTFE offers enhanced strength and wear resistance.

- Carbon-filled PTFE improves wear resistance without significantly increasing friction.

- MoS2 (molybdenum disulfide) is added to increase wear resistance and improve performance in high-duty or dry-running applications.

Virgin PTFE vs. Filled Grades

The selection between a virgin or filled grade is a critical trade-off. Virgin PTFE is typically used in slower, low-duty applications or where absolute chemical purity is required (food and medical).

Filled grades are necessary for applications involving high pressure, high speed, or abrasive media where durability and wear resistance are the primary concerns.

Seal Design and Configuration

Beyond the material, the physical design of the seal lip (e.g., plain, multi-lip, or hydrodynamic) can be tailored to the application's specific needs for containing pressure or providing tighter sealing at high speeds.

Making the Right Choice for Your Application

To select the appropriate PTFE rotary shaft seal, you must align the material and design with your primary operational goal.

- If your primary focus is chemical purity and hygiene: Choose a seal made from virgin PTFE to ensure no fillers can leach into the process media.

- If your primary focus is mechanical wear and durability: Select a filled PTFE, such as carbon or glass-filled, to provide the necessary strength for high-pressure or abrasive environments.

- If your primary focus is high speed with limited lubrication: Look for MoS2-filled grades and specialized hydrodynamic lip designs to minimize friction and manage heat generation.

Ultimately, selecting the correct PTFE seal is a critical step in engineering reliable and long-lasting industrial and high-performance equipment.

Summary Table:

| Environment/Challenge | PTFE Seal Capability | Key Benefit |

|---|---|---|

| Aggressive Chemicals | High chemical inertness | Resists acids, solvents, and industrial fluids |

| Extreme Temperatures | Stable from -200°C to +260°C | Prevents brittleness or degradation |

| High Rotational Speeds | Low friction, reinforced with fillers | Maintains integrity under high PV conditions |

| Low/No Lubrication | Effective dry-running performance | Reduces heat and wear in demanding applications |

Need a PTFE rotary shaft seal that can withstand your harshest operating conditions? KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a seal tailored to your exact chemical, temperature, and speed requirements.

Contact us today to discuss how our PTFE solutions can enhance your equipment's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry