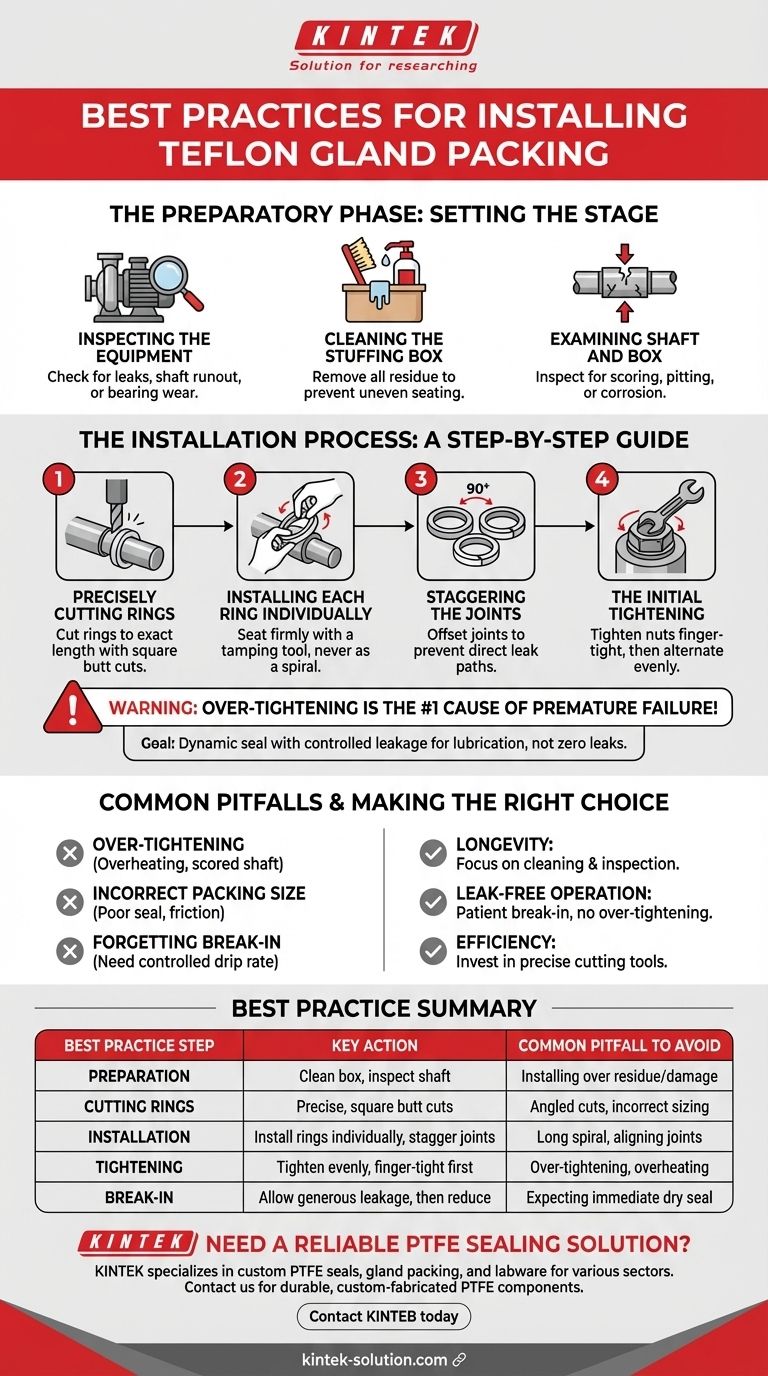

The best practice for installing Teflon gland packing is a precise, methodical process focused on cleanliness and correct compression. It involves meticulously cleaning the stuffing box, accurately cutting each packing ring, installing them one at a time with staggered joints, and tightening the gland follower just enough to control leakage without strangling the shaft.

The primary goal of gland packing installation is not to completely eliminate leaks through brute force, but to create a dynamic seal that allows for minimal, controlled leakage for lubrication. Over-tightening is the single most common cause of premature packing and equipment failure.

The Preparatory Phase: Setting the Stage for Success

Proper preparation is responsible for more than half of a successful installation. Skipping these steps ensures that even the highest quality packing will fail prematurely.

### Inspecting the Equipment

Before removing the old packing, carefully inspect the pump or valve. Check for any existing leaks, shaft runout, or bearing wear. New packing cannot fix underlying mechanical problems.

### Thoroughly Cleaning the Stuffing Box

Once the old packing is removed, the stuffing box and shaft must be cleaned completely. Any remaining residue, scale, or grit will cause the new packing to seat unevenly and can score the shaft.

### Examining the Shaft and Box Condition

Inspect the shaft or stem for scoring, pitting, or corrosion. A damaged surface will quickly shred new packing. Likewise, check the inside of the stuffing box for any wear or damage that could compromise the seal.

The Installation Process: A Step-by-Step Guide

Precision and patience during the installation itself are critical. Rushing this stage will lead to rework and unnecessary downtime.

### Precisely Cutting the Packing Rings

Each packing ring must be cut to the exact length required. Use a dedicated packing cutter and a mandrel of the exact same diameter as the shaft to ensure a clean, square butt cut. Angled or "skive" cuts are not recommended for most applications.

### Installing Each Ring Individually

Never install packing as one long spiral. Each pre-cut ring must be installed individually. Open the ring with a twisting motion to avoid damaging its structure, place it over the shaft, and seat it firmly at the bottom of the stuffing box using a tamping tool or a split bushing.

### Staggering the Ring Joints

Install subsequent rings one at a time, ensuring the joint of each new ring is offset by at least 90 degrees from the previous one. This staggering prevents a direct leak path from forming along the shaft.

### The Initial Tightening Sequence

After the final ring is installed, bring the gland follower down evenly. Tighten the nuts finger-tight first. Then, use a wrench to tighten each nut one or two flats at a time, alternating between them to ensure the follower remains parallel to the stuffing box face.

Common Pitfalls to Avoid

The difference between a long-lasting seal and a quick failure often comes down to avoiding a few common mistakes.

### The Dangers of Over-Tightening

This is the most critical error. Over-compression prevents the packing from receiving necessary lubrication from the process fluid, causing it to overheat and harden. This leads to a glazed packing surface, a scored shaft, and ultimately, catastrophic leakage.

### Using Incorrectly Sized Packing

Using packing with a cross-section that is too small will make it impossible to achieve a proper seal. Packing that is too large will be difficult to install and will generate excessive friction and heat once compressed.

### Forgetting the Break-In Period

Newly installed packing requires a short break-in period. Start the equipment and allow for a generous leakage rate. Gradually tighten the gland follower nuts in small increments (e.g., one-sixth of a turn) over the first hour of operation until leakage is reduced to a controlled drip rate suitable for lubrication.

Making the Right Choice for Your Goal

Your approach to installation can be fine-tuned based on your primary objective for the equipment.

- If your primary focus is maximum equipment longevity: Prioritize meticulous cleaning and a thorough inspection of the shaft and stuffing box before you begin.

- If your primary focus is leak-free operation: Resist the urge to over-tighten on startup; instead, commit to a patient break-in and adjustment period to achieve a stable, minimal drip rate.

- If your primary focus is operational efficiency: Invest in precise cutting tools and sizing mandrels to ensure every ring is perfect, enabling a faster and more reliable installation every time.

Ultimately, a successful installation transforms Teflon gland packing from a simple component into a high-performance, reliable sealing system.

Summary Table:

| Best Practice Step | Key Action | Common Pitfall to Avoid |

|---|---|---|

| Preparation | Thoroughly clean stuffing box & inspect shaft for damage. | Installing packing over old residue or a scored shaft. |

| Cutting Rings | Use a mandrel and cutter for precise, square butt cuts. | Using angled cuts or incorrect sizing. |

| Installation | Install rings individually, staggering joints by 90+ degrees. | Installing as one long spiral or aligning joints. |

| Tightening | Tighten gland follower evenly and gradually, starting finger-tight. | Over-tightening, which causes overheating and failure. |

| Break-In | Allow generous leakage at startup, then gradually reduce to a drip. | Expecting a completely dry seal immediately. |

Need a Reliable PTFE Sealing Solution?

Proper installation is critical, but it starts with high-quality, precision-manufactured PTFE components. KINTEK specializes in custom PTFE seals, gland packing, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our commitment to precision ensures a perfect fit and superior performance.

Contact KINTEB today to discuss your specific application and get a quote for durable, custom-fabricated PTFE components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the advantages of using PTFE Lip Seals in high-speed rotary applications? Achieve Superior Speed and Reliability

- How do PTFE and NBR oil seals compare in terms of chemical resistance? A Guide to Superior Seal Performance

- What are the unique properties of PTFE that make it suitable for CNC machining? Master Machining for Superior Components

- What types of fluids can PTFE O-Rings repel? The Ultimate Guide to Chemical Resistance

- Why is 5-axis CNC machining commonly used for Teflon? Master Complex PTFE Parts with Precision

- What are the benefits of PTFE's flexibility compared to rigid plastics? Superior Sealing in Dynamic Applications

- What are the properties of 10% PEEK-filled PTFE bushings? Enhance Wear Resistance & High-Temp Performance

- How do PTFE expansion bellows contribute to pollution control systems? Enhance System Integrity & Safety